Blue Alchemist Clears CDR, Bringing Lunar Factories Near

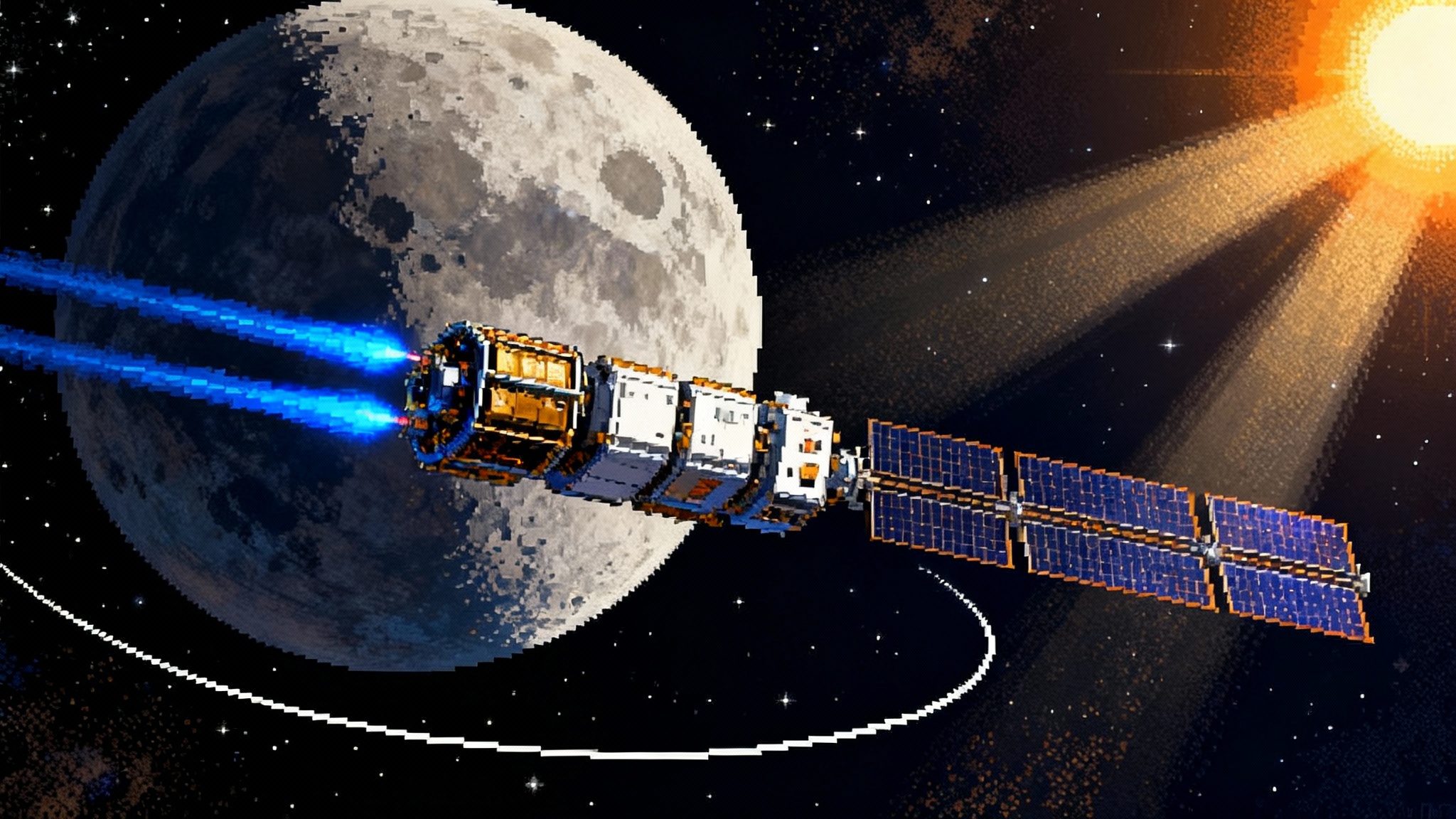

Blue Origin’s Blue Alchemist has passed Critical Design Review, moving molten regolith electrolysis from pitch deck to practice. Here’s how a 2026 autonomous demo could unlock lunar oxygen, metals, and locally made solar power for Artemis.

A milestone that moves lunar industry from pitch deck to playbook

On September 10, Blue Origin announced that Blue Alchemist, its in‑situ resource utilization system, cleared Critical Design Review. The company framed the CDR as the last major gate before an autonomous demonstration in a simulated lunar environment in 2026. If Blue Alchemist performs as advertised, it could turn lunar soil into solar arrays, structural metals, and oxygen for crews and propellant. That is the difference between hauling everything from Earth and bootstrapping a supply chain on the Moon. The claim is significant enough to start here, with the source in hand: Blue Alchemist’s CDR announcement on Sept. 10.

For broader context on how ISRU is reshaping lunar planning, see our look at the Chang’e‑6 lunar ISRU strategy.

What molten regolith electrolysis actually does

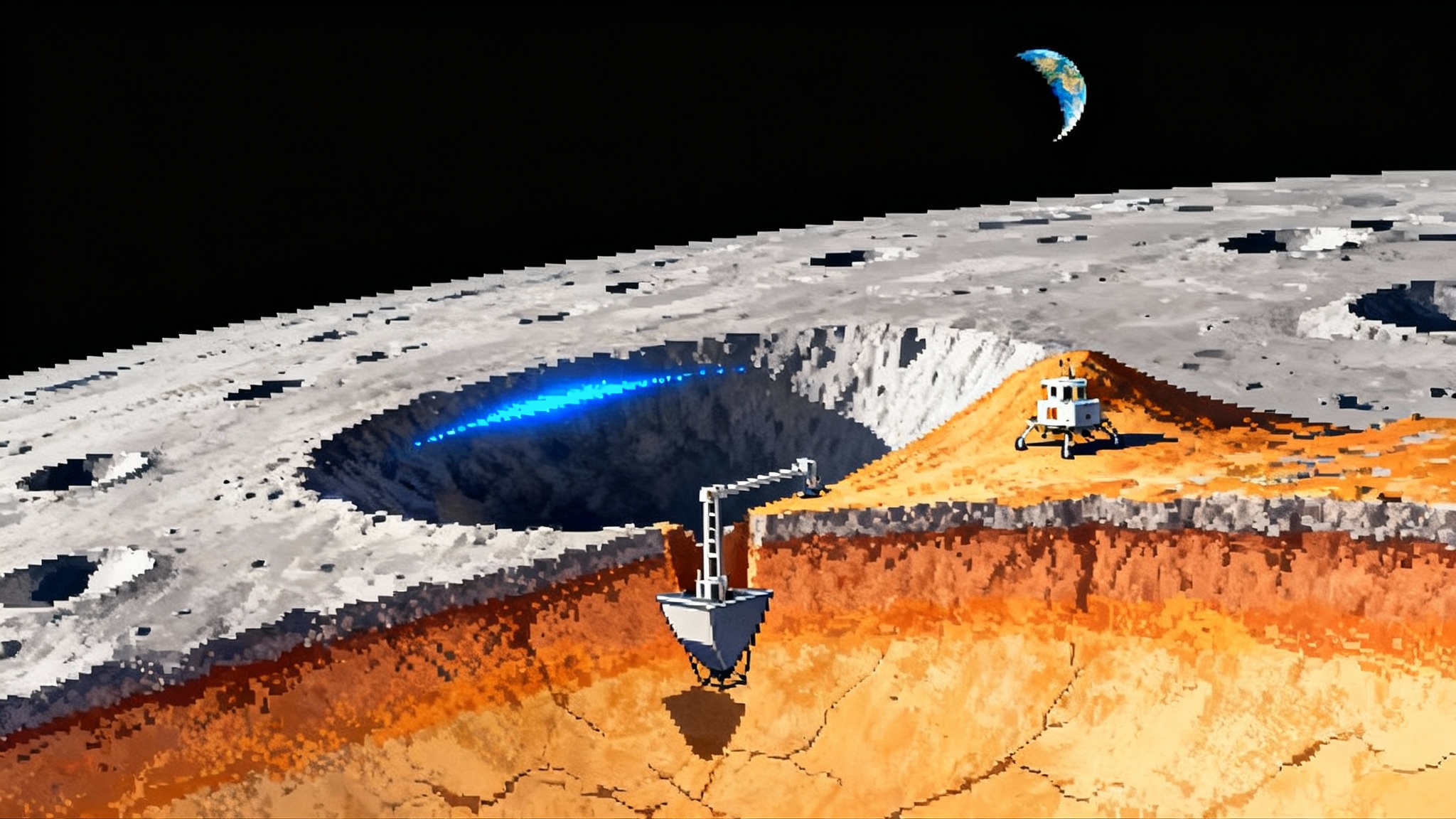

Molten regolith electrolysis, or MRE, is a high temperature process that takes the jumbled oxides inside lunar soil and separates them into oxygen and metals by running current through a molten bath. Lunar regolith is rich in oxygen bound into compounds like silicates and metal oxides. In plain language, the process melts the dirt, pushes electrons through it, and frees oxygen at one electrode while leaving a mix of metals and metalloids at the other. With the right reactor geometry, electrodes, and separations steps, that metal mix can be sorted into iron, aluminum, and silicon. Silicon can then be refined further into feedstock for photovoltaic cells. Oxygen can support life support, fuel cells, or become oxidizer for landers.

The beauty of MRE is what it does not need. There is no water feedstock to mine and purify, no imported hydrogen to regenerate, and no carbon-based reagents to ship from Earth. The output map matches exactly what early lunar infrastructure craves. Metal for frames and radiators. Silicon for solar cells and glass. Oxygen for tanks and habitats. The process produces these in one integrated thermal and electrical system that, once started, grows the local power and materials base.

Why CDR is a pivotal gate, not just a press release line

Most space hardware marches through a sequence of design gates. Preliminarily you define what the system must do. You trade architectures and size subsystems. You test materials in the lab and learn where the contaminants hide. A Preliminary Design Review checks that the concept can close on paper. A Critical Design Review is different. CDR is where the design is baselined across interfaces, manufacturing methods, test plans, and safety margins. It is the point where drawings are release-grade, parts lists are real, vendors are chosen, and the team can start building with traceable configuration control. Getting through CDR means a program is ready to spend most of its money on hardware rather than on slides and breadboards. It is also the point where hidden coupling risks are forced into the open, because everything from power converters to thermal straps to autonomy software must close together.

What happens next in 2026

Blue Origin says the next step is an autonomous demonstration in a simulated lunar environment in 2026. That phrase matters. Simulated lunar environment is more than a sandbox. It implies vacuum or reduced pressure, thermal swings representative of the lunar day, abrasive dust simulants, and power constraints that mimic lunar operations. It implies continuous runs long enough to encounter corrosion, slag buildup, and electrode degradation. It implies autonomy that can start, steady, and safely shut down the reactor without a person in the loop. If Blue Alchemist can show stable oxygen production, metal extraction with repeatable purity, and a closed-loop thermal balance under these conditions, it will validate not just a chemistry set, but a factory cell.

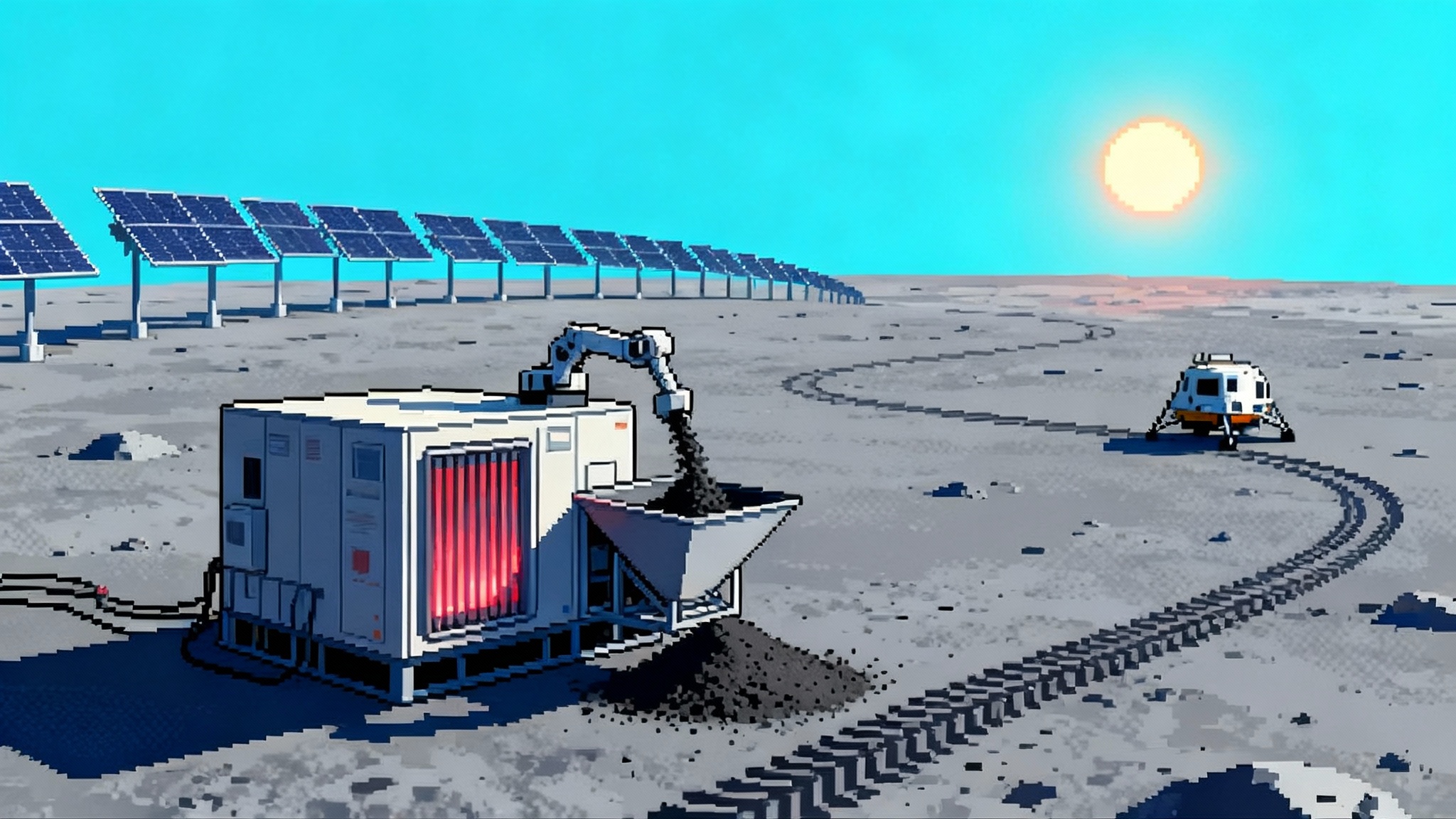

The company’s stated ambition reaches beyond oxygen toward photovoltaic manufacturing. Producing silicon cells on the Moon removes a massive fraction of the mass of solar power systems from launch manifests. If the demo can print or assemble even small strings of cells on glass and integrate them into ruggedized panels, that would be a landmark.

The bottleneck everyone worries about first is power

Every industrial process on the Moon starts with a power budget, and MRE is energy hungry. Early operations will rely on delivered power systems, then transition to locally built arrays or to nuclear. This is where the broader Artemis ecosystem matters. NASA is maturing fission surface power concepts at the 10 to 40 kilowatt scale, with the intent to operate continuously through night and shadow. If even one such unit is available as a bootstrap power plant, it could feed an MRE line that in turn fabricates solar panels to expand the grid. Readers who want the official context can start with NASA’s Fission Surface Power program.

Artemis planning also depends on forecasting radiation storms and power-safe operation. For that angle, see how the L1 Trio space weather for Artemis could change surface tempo and safety margins.

There is a virtuous circle on the table. Imported nuclear power makes the first MRE silicon and oxygen. That silicon expands solar capacity. More solar feeds more MRE, which makes more structures, which mount more arrays. Eventually oxygen production supports long duration landers and tankers, which start closing the logistics loop. That is how a site stops acting like a one-off expedition and starts behaving like a base.

Artemis logistics through an ISRU lens

Launch capacity to lunar surface is precious. Tanks and batteries are heavy. Oxygen is the heaviest part of many propellant mixes. Structures for arrays and radiators do not care how smart the rocket is; mass is mass. If oxygen and metals can be produced on site, uncrewed cargo flights can be retasked from hauling commodities to hauling specialized equipment that cannot be made locally yet. Habitat modules can arrive without their full complement of consumables and still be safe because the local plant will fill them. Tankers can land nearly dry and leave full. Surface crews can use oxygen for fuel cell regeneration during the long lunar night rather than consume it from a ship manifest.

Even with ISRU, there is an optimization dance between delivered power, delivered spares, and the output rate of the plant. The first generation will likely run as a pilot line with careful duty cycles and frequent inspections. But every kilogram of oxygen and metal produced on site compounds into future missions. Over a campaign of years, that compounding dominates.

Why solar made on the Moon changes the equation

Solar arrays are attractive on the Moon because they are simple and scalable. They also suffer from the lunar night and low Sun angles near the poles, and they need careful dust mitigation. Making arrays locally does not solve night, but it does solve replenishment and growth. If a panel is abraded, replace the glass. If a string fails, print another. The heavy items become the specialized tools, dopants, and control boards rather than the glass and silicon slabs. A site with a functioning MRE-to-solar pipeline can trade time for mass and slowly build acreage to feed power-hungry processes like electrolysis, metallurgy, and ice mining.

Two other knock-on effects matter. First, on-site glassmaking enables robust windows, habitats with hardened viewports, and mirrors for concentrated solar thermal systems. Second, metal byproducts enable everything from cable trays to radiator fins to regolith-handling buckets. None of these will look like Earth factory outputs at first, but they do not have to. They have to be good enough in lunar gravity to do work and survive dust.

The competitive and collaborative landscape

Blue Origin’s push arrives in a field that is suddenly active. Several teams are chasing oxygen from regolith using carbothermal reduction or molten salt electrolysis. Others focus on water ice extraction and purification, which taps different physics and different geologies. A few are exploring solar-thermal extraction or direct sintering of regolith into bricks. On the power side, commercial and national teams are competing to deliver fission surface power units and high voltage distribution. Lander providers are racing to become routine carriers of heavy cargo to the surface. Robotics firms aim to be the muscle that moves regolith, loads reactors, and places arrays with millimeter precision.

Competition will be healthy here because no one method fits all latitudes and mission phases. Carbothermal routes may suit certain mineralogies. MRE may thrive where feeder power is reliable and silica content is favorable. Ice extraction dominates where volatiles are accessible. Over time, a mature base will likely mix all three. The real contest is not process versus process, but which stack can be fielded, maintained, and expanded with the least crew time and the lowest spare parts burden.

Key technical risks to watch

- Startup power and thermal control. MRE likes steady, high temperature operation. Getting there without cracking crucibles or spiking power lines is nontrivial. A bootstrap sequence needs to be robust, repeatable, and safe after interruptions.

- Electrode and crucible lifetime. Molten oxide baths are chemically aggressive. Consumable parts that erode faster than expected can kneecap availability. Long duration coupon tests and in situ inspection will tell the truth.

- Materials handling in one-sixth gravity. Regolith is abrasive, charged, and eager to infiltrate bearings and seals. Conveyors, feeders, and separators must work without clogging. Gentle handling often conflicts with throughput.

- Purity versus throughput. Photovoltaic-grade silicon is a high bar. The plant must hit purity targets predictably, not just in one-off laboratory runs. If purity slips, solar efficiency drops and the acreage needed to hit power goals grows.

- Dust and thermal cycling. Day to night swings and sharp shadows can punish structures and seals. Dust can coat radiators and panels, raising temperatures and dropping output. Cleaning and passive dust control are as critical as core chemistry.

- Autonomy and fault management. The demo promises autonomous operation. That implies a control stack that can detect off-nominal conditions, gracefully back down, and recover without human intervention. A lunar plant must be a good citizen on a shared power bus and radio network.

- Integration with landers and power grids. Oxygen, metals, and panels are useful only if they tie into storage tanks, fabrication jigs, and distribution systems. Interfaces with landers, tankers, and grid controllers need to be defined early and tested.

Risk is not failure. Risk is a to-do list. The right tests convert these unknowns into engineering margins and maintenance procedures.

What success looks like in the 2026 demo

Engineers will watch for specific signatures. Oxygen production should be stable within a narrow band without runaway temperature oscillations. Metal separation should produce repeatable compositions that match the control logic in the plant. Thermal balance should show radiators and insulation keeping the reaction in its sweet spot without bleeding power. Power draw should plateau at a planned value rather than hunting. On the autonomy side, the software should gracefully handle feedstock changes and staged shutoffs, then restart without technician tricks.

If solar cell fabrication is included, the metrics change from chemistry to performance. The key indicator is cells that hit target efficiency and survive thermal cycling without cracking or browning. A small panel that produces stable wattage under realistic illumination and dust exposure will be worth more than a glossy wafer on a lab bench.

How this could reshape Artemis pacing and priorities

If Blue Alchemist proves practical, Artemis mission planners gain an option they have not had since the program’s inception. They can plan on a ramp curve of local oxygen and power rather than treating these as static deliveries. That enables new mission types. Tanker sorties that lift off the Moon full, not empty. Long stay crews with generous life support reserves. Prospecting robots that roam farther because recharge points multiply. Construction activities that schedule around growing power windows rather than tight battery budgets. The difference between a site that can manufacture its own arrays and oxygen and a site that cannot is the difference between a camp and a settlement.

The change will not be overnight. Power, spares, and crew time are still scarce. Operations will be conservative and methodical. But as months turn into years, the incremental gains stack. A reactor that runs for thousands of hours and a panel line that keeps growing acreage are compounding assets. In the late 2020s and early 2030s, the programs that compound will own the surface tempo.

The bigger idea hiding in plain sight

Space industry has learned that the decisive advantage often comes from logistics, not thrust. Starship class lift, lunar landers with precision touchdown, and surface nuclear power are all logistics revolutions. Blue Alchemist is a proposal to add one more. If the Moon can make some of its own power, metals, and oxygen, then surface operations scale with time spent on the Moon rather than with how many rockets leave Earth each year. That is the kind of scaling that enables boring, daily work. Daily work builds roads and habitats, not just headlines.

What to watch between now and first dust in the reactor

- Evidence that the demo rig is built to flightlike interfaces. The closer the ground demo is to a surface-ready package, the less rework later.

- Signs of partnership with power providers and lander teams. If Blue Alchemist shows up with defined connectors, mounting points, and tankage interfaces, integration risk drops.

- Data on run hours and maintenance intervals. Lifetime curves will tell whether the first plant is a lab queen or a field hand.

- A credible plan for dust management, including coatings, electrostatic mitigation, and vacuum-friendly cleaning.

- Early validation of cell performance if panel manufacturing is part of the demo. A few square meters producing stable power in a harsh chamber will be a strong signal.

Bottom line

Blue Alchemist clearing CDR is a real step. It sets the stage for a 2026 autonomous demo that can answer the only questions that matter now. Can MRE run steadily under realistic conditions. Can the plant make oxygen and metals at rates that justify their power draw. Can those outputs be turned into arrays and structures that stand up to lunar heat and dust. If the answers are yes, Artemis gains a flexible lever on the hardest part of space exploration, which is not how to get somewhere, but how to stay. A Moon that can make its own oxygen and power is not just a destination. It is a workshop where the next decade of spaceflight learns how to live off the land.