Flight 11 and Block 3: The Turn to Operational Reuse

Starship Flight 11 closes the Block 2 era and points to a practical Block 3. Catching the booster, hardening the heat shield, and proving propellant transfer could compress costs and make monthly cislunar runs routine.

The hinge flight that changes the script

Call this the moment the practice game became the season opener. With Flight 11, the giant stainless steel rocket crossed a boundary that felt less like another test and more like a pivot. Block 2 was about proving that the world’s largest launcher can light, fly, and survive. Block 3 is about running it as a system. That means catching the booster, keeping tiles on through brutal heating, and moving propellant in orbit with the reliability of a fuel hose at a truck stop. If those three threads come together, the price of deep space tonnage bends down fast, schedules compress, and a monthly cislunar cargo rhythm moves from talk to timetables.

Here is why Flight 11 matters. It is the last clear snapshot of the Block 2 architecture before the company locks in the operational changes of Block 3. Two years from now we may look back on this flight the way aviation historians look at early jetliners that still wore the habits of propellers. The airframe was familiar, the intentions were different. After Flight 11, the intention is operational reuse.

What Block 3 sets out to change

Block 3 is not a paint job. It is a rebalancing of the entire risk and cost stack around three pillars: tower catches for the booster, a more robust thermal protection system, and early in‑orbit propellant transfer that stops being an experiment and starts being a checklist. Each is a lever. Together they change the economics.

- Catching the booster trims the time and money now spent protecting and recovering a stage from the sea, and it eliminates much of the refurbishment that salt water loves to create. It also shortens the distance between landing and liftoff, because the stage returns directly to the launch mount, not a barge or a dockyard.

- A tougher heat shield reduces tile work and the latent risk of carbonization and hot gas ingest during reentry. It moves the ship from flying demonstrations to dependable returns with consistent turnaround time.

- Propellant transfer in orbit is the key that unlocks heavy payloads beyond low Earth orbit without building an even bigger first stage. It creates a depot mindset, where tanker flights fill a tank up top, and the mission vehicle leaves when the gauge reads full.

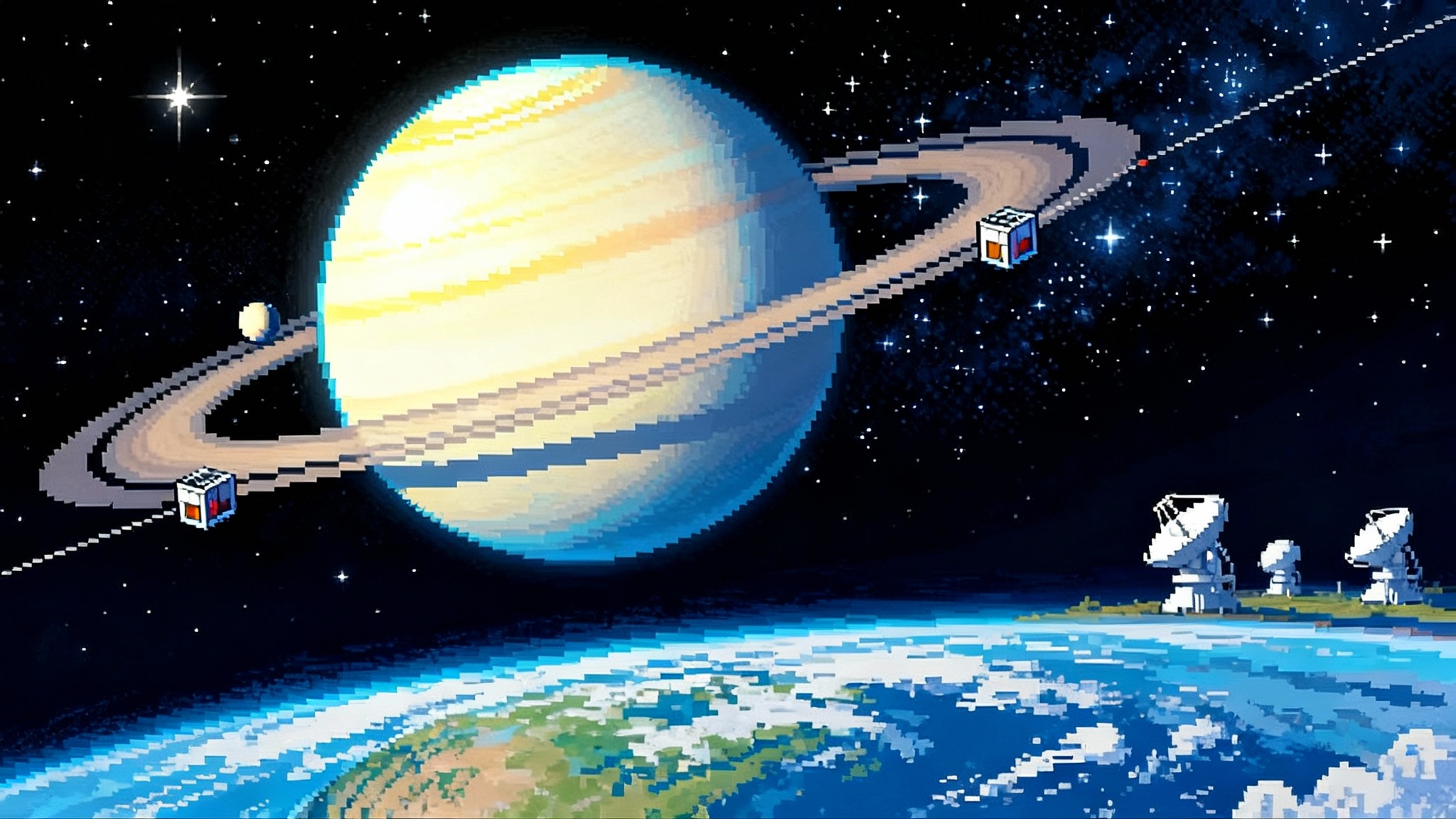

SpaceX has telegraphed all three ideas for years, including the plan to catch the Super Heavy booster with the launch tower arms, often nicknamed chopsticks, set into a structure the company calls Mechazilla. The company’s public materials explain the catch as a way to improve turnaround and lower cost per launch, and they have tested precision guidance and grid fin control for it in earlier flights. For readers new to the program, the SpaceX Starship overview lays out the basic architecture.

The catch: turning a stunt into a service procedure

Catching a stage with tower arms seems theatrical until you model it as a materials and logistics problem. Ocean recovery adds corrosion risks to a structure that is part plumbing and part engine bell. Even when the booster lands on a barge, it rides back at ocean speeds, sometimes in poor weather, which stretches the post‑flight calendar. By contrast, a tower catch is like a factory receiving dock. You set the time, you know the address, and the part arrives at the workstation that will prep it for the next job.

The mechanism is simple to describe and demanding to execute. Grid fins steer the booster to the vertical corridor above the pad. Thrusters and engines adjust the final meters per second. Computer vision and radar confirm position and velocity. The arms close around two reinforced points on the booster structure and accept the load. If the ship is a flying refinery, that tower is the gantry crane that makes the refinery profitable.

The real gains are not in acrobatics but in the removal of steps. No barge transit, no crane at sea, no port scheduling, no salt spray on heat exchangers, fewer fasteners that need retorquing. Shorter critical path means more launches per month with the same hardware. If Block 3 makes catches routine, the operational tempo that leadership has described moves from ambition to arithmetic.

For context, think about airline ground operations. A plane that spends two extra hours waiting for a gate is not just late. It costs the airline a cascade of crew, fuel, and maintenance penalties that ripple across the day. The tower catch is the equivalent of guaranteeing your gate every time. You eliminate the tail of random delays that quietly murder cadence.

The heat shield: from survival to schedule

Starship’s heat shield tiles must do more than keep the structure cool. They must be installed and removed without turning every turnaround into a tile‑by‑tile inspection project. Early flights showed where shock, acoustic loads, and thermal gradients wanted to pry and rattle tiles loose. Block 3 hardens the tile mounts, rationalizes the gap fillers, and protects vulnerable edges with better carrier panels and fasteners. The aim is simple. Make the belly a piece of industrial equipment, not a mosaic that demands an artisan’s hand every time.

Thermal protection is a reliability game as much as a thermal one. When a tile departs, it often creates local heating that can propagate damage. When tiles stay put, they also protect surrounding tiles, mounts, and sensors. The result is a ship that reenters with its underside intact, making landing and post‑flight checks shorter and more predictable. Predictability is the fuel of operations.

Think of it like a fleet of delivery vans. If a certain model has a weak door latch, you do not just train drivers to shut doors more carefully. You fix the latch. The heat shield changes in Block 3 are the latch fix.

Propellant transfer: the missing plumbing

Propellant transfer in orbit is the enabler for missions beyond low Earth orbit without a larger rocket. Liquid methane and liquid oxygen are cryogenic fluids that must be kept cold, settled, and flowing in microgravity. The company has already practiced tanker rendezvous profiles during past flights, but Block 3 places this capability on the near horizon as an operational goal. The process demands chilldown of lines, precise pressure management, and control of fluid slosh using attitude thrusters. None of this is science fiction. All of it is engineering that must behave like a gas station, because mission vehicles will rely on it for every serious destination beyond low Earth orbit.

This is also the piece NASA cares about for Artemis. Human landing system missions need a lot of propellant at the right time in the right orbit. That is why cryogenic transfer is a named requirement and a funded milestone in the lunar architecture. For an accessible overview of the government side, see the NASA Artemis program, which explains the need for a lander that can be fueled in space and why that creates a service market for tankers and depots. For related lunar payload context, revisit our VIPER reboot and landing.

How the three levers collapse cost

Catching the booster cuts ground time and ocean operations. A tougher heat shield cuts post‑flight inspection hours and parts attrition. Propellant transfer creates a product, which is propellant in a destination orbit, that can be sold repeatedly without building new first stages. Together they change the cost per delivered kilogram in two ways at once: by reducing the denominator, which is refurbishment time and overhead per flight, and by increasing the numerator, which is revenue‑producing mass delivered per calendar month.

Here is a simple model. Suppose a Block 2 style operation can turn a booster around in 30 days after a barge recovery and port processing, and suppose a Block 3 catch reduces that to 10 days on average. That is a threefold improvement on that line item. Add a heat shield improvement that reduces ship rework from 500 labor hours to 150. Add an operational propellant transfer that allows the same combined hardware set to support two mission vehicles per month instead of one. These are illustrative numbers, not official targets, but the direction is clear. When an asset that once spent most of its life waiting can fly three times as often, unit cost falls even before you count lower refurbishment bills. Frequency is a discount.

The economic punchline is the compounding effect. If Block 3 enables two or three completed tanker stacks per month and one mission stack per month, a service profile emerges: tanker flights during most weeks, a refueled mission vehicle that departs roughly monthly, a booster and tower cycling through a steady rhythm of fuel, fire, catch, and prep. The fixed costs of the pad, the tower, and the workforce are spread over many more flights. The marginal cost of each additional mission declines with cadence.

The two‑year picture: cislunar shipping as a schedule, not a slogan

The angle that matters is the calendar. A monthly cislunar cargo run means that if you miss a window, you are not waiting seasons. You are waiting a few weeks. That is how supply chains are born. The path to such a cadence is not mystical. It has five steps:

- Lock in tower catches for the booster so the turnaround is measured in days and weeks, not weather and sea states.

- Stabilize heat shield performance so a ship returns in a known condition and goes back to the factory floor with routine inspections rather than detective work.

- Demonstrate propellant transfer between a tanker and a receiver in low Earth orbit, then repeat until it looks boring.

- Build a small depot habit, even if the depot is nothing more than a tanker that loiters with partial propellant for days without excessive boiloff.

- Commit to a monthly beat with a simple cargo destination, likely near rectilinear halo orbit, and ship standard payload pallets and pressurized drums until the dockworkers at the receiving end can predict the incoming mass with their eyes closed.

If that sounds like maritime logistics, it is meant to. Cislunar space is a sea lane. You need a port near low Earth orbit, a mid‑ocean transfer station, and a reliable day boat that runs the route. In this analogy the tower is the quay crane, the depot is the mid‑ocean rig, and the mission ship is the day boat. Once the route exists, cargo finds it.

What changes for Artemis

A service that can put dozens of tons into near rectilinear halo orbit every month changes NASA’s program math. Spare tanks and replacement pumps can ride along even when they are not strictly necessary. Lunar surface missions can carry more margin and more science instruments. The Gateway modules can be assembled and upgraded with less drama. Most importantly, risk management shifts. When the next shipment is weeks away, you plan differently.

NASA also gains contracting leverage. If cislunar transport becomes a commercial service with published performance, the agency can procure capacity as needed rather than locking in bespoke launches for each mission. That does not eliminate the need for careful integration and safety reviews, but it lowers the premium that uncertainty usually imposes. In budget terms, a monthly cargo rhythm lets mission planners treat transport as a service line item rather than a bespoke project.

The new commercial space economy beyond the Moon

Reliable tonnage to cislunar space is the doorway to private interplanetary missions. Not because a Starship needs to go everywhere, but because a reliable way to fuel and stage in high Earth or lunar orbits lowers the barrier for companies and universities to send physics experiments, small landers, sample return missions, and even solar power prototypes. A startup that once pitched a one‑ton asteroid miner as a decade‑long project can instead plan for a hosted payload on a cislunar cargo flight next spring, with a dedicated departure later that summer. The same cadence pressures will reshape sample‑return timelines, as explored in Mars samples return outlook.

This is the same pattern that powered digital startups when cloud computing replaced owned servers. When capacity is on tap, imagination is less gated by capital expenditure. Expect companies to appear whose entire product is a piece of the cislunar supply chain: cryogenic docking rings, depot thermal blankets, propellant quality sensors, autonomous inspectors, and insurance products priced per delivered kilogram to a specific orbit.

Expect universities to field entire classes that build payloads sized to a standard pallet, akin to CubeSat standards but aimed at cislunar destinations.

The competition will adapt

Space is a big market, and competitors do not sit still. Blue Origin will push hard on its own heavy architecture as it matures, and United Launch Alliance will emphasize precision and reliability for payloads that value a particular orbit or timeline. International providers will court national space agencies with integrated packages that include launch, operations, and data return. For a broader look at private heavy‑lift momentum, see our New Glenn to Mars briefing. All providers will also look for partnership slots in the cislunar logistics chain, because even rivals will want regular, low‑cost access to a depot if it becomes the default on‑ramp to the Moon.

The larger point is that Block 3 pressures everyone to think in services, not flights. If your vehicle is optimized for bespoke missions with long lead times, you will be asked how your design plugs into a world where there is a fuel dock upstairs and a ship leaving for lunar orbit every month.

Risks that still matter

Three things can slow the pivot.

- Catch reliability: The first booster catches must work not once but repeatedly. Even a single bad day can reset confidence and schedules.

- Tile attrition: If heat shield improvements do not translate into lower maintenance hours, the calendar gains will be eaten by the belly of the ship.

- Transfer complexity: Propellant transfer can suffer from sensor noise, thermal transients, and unexpected slosh dynamics. The cure is iteration, but iteration requires a steady drumbeat of flights.

Regulation and range operations are the fourth wildcard. A monthly cadence means predictable windows, strong coordination with the Federal Aviation Administration and the range, and infrastructure that can handle more frequent closures without burning community goodwill. That implies more investment at the pad and more automation across the countdown and recovery steps.

A practical roadmap from Flight 11 forward

Think of the next 24 months as four seasons of work.

- Season 1: Close out Block 2 lessons. Validate the new booster hardware for catching with extended hover capability, tuned guidance, and reinforced hardpoints. Begin ground rehearsals with the tower arms that simulate dynamic capture without committing to a full catch.

- Season 2: Attempt the first live catches under bounded conditions, such as a slightly lighter booster and a conservative wind limit. In parallel, fly a ship with a fully updated tile set and document the work hours needed after landing.

- Season 3: Conduct propellant transfer demos that focus on repeatability. Start with small volumes, progress to mission‑relevant quantities, and include boiloff measurements over days, not hours. Set a depot availability target and meet it three months in a row.

- Season 4: Declare a standing route to near rectilinear halo orbit. Publish booking guidance for standard cargo pallets and offer integration kits that reduce one‑off engineering. Keep the price simple and reward regular customers with priority windows.

By the end of that sequence, the difference between Block 2 and Block 3 will be obvious. Block 2 proved that a giant rocket can work. Block 3 would prove that a giant rocket can be run.

What to do now if you are a stakeholder

- NASA program leads: Write task orders that assume monthly cislunar lift. Ask vendors to design payload interfaces that can sail on a tanker stack without custom harnesses. Tie milestone payments to delivered mass in a specific orbit.

- Startups: Put a cislunar pallet on your next seed deck. Define a payload you could field in nine months, then a larger one for month eighteen. Partner with a thermal analysis group now so your hardware is depot and loiter ready.

- Insurers: Build a product priced per cislunar kilogram with discounts for payloads that meet standard handling and interface rules. The first to price this cleanly will define the risk curve for everyone else.

- Universities: Stand up a shared cislunar lab course. Teach guidance, cryogenics, and radiation test skills in one studio and graduate teams that can deliver flight‑ready hardware every semester.

- Policymakers and port authorities: Prepare for higher pad throughput. That means road closures with better communication, lightning‑safe shelters for residents and workers, and fast crane access for tower maintenance.

The takeaway

Flight 11 was the hinge. Block 3 is the door. The catch makes the booster a factory part, not a traveler. The heat shield turns the ship into a reliable truck, not a prototype. Propellant transfer makes orbit a service station, not a destination. When you combine those three, cadence and cost bend together.

Two years from now, the most interesting thing about this rocket may not be its size or flame. It may be its schedule. A ship that leaves for lunar orbit every month is not spectacular. It is normal. And in space, normal is new. When normal arrives, the rest of the economy shows up. That is the operational turn that Flight 11 announced, and that Block 3 must deliver.

If you want a deeper sense of how routine access reshapes exploration, compare this pivot with our New Glenn to Mars briefing and the lunar tempo discussed in VIPER reboot and landing. For newcomers to the vehicle, the SpaceX Starship overview is a helpful primer.