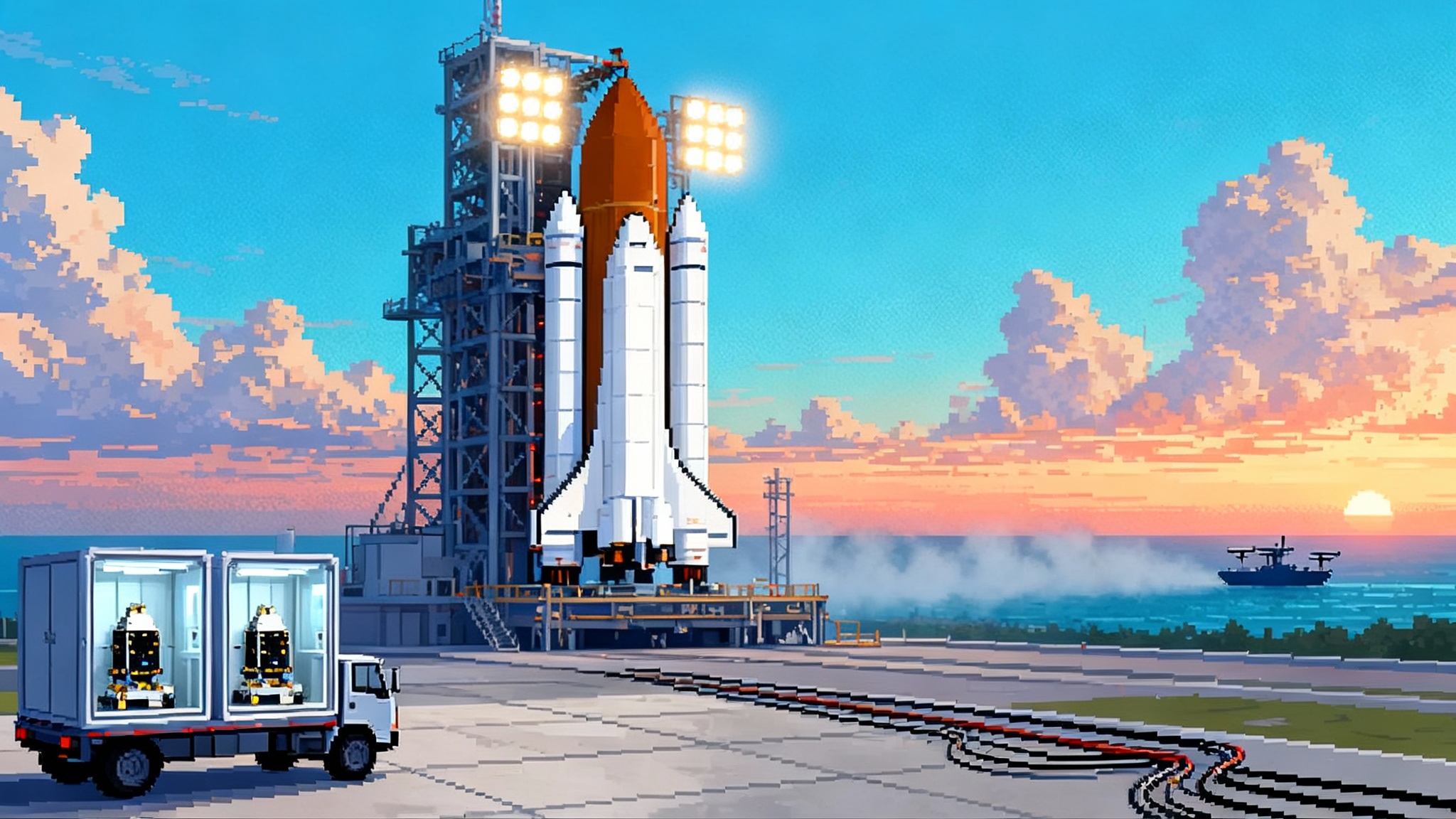

Dragon’s trunk boost kit gives the ISS a new lifeline

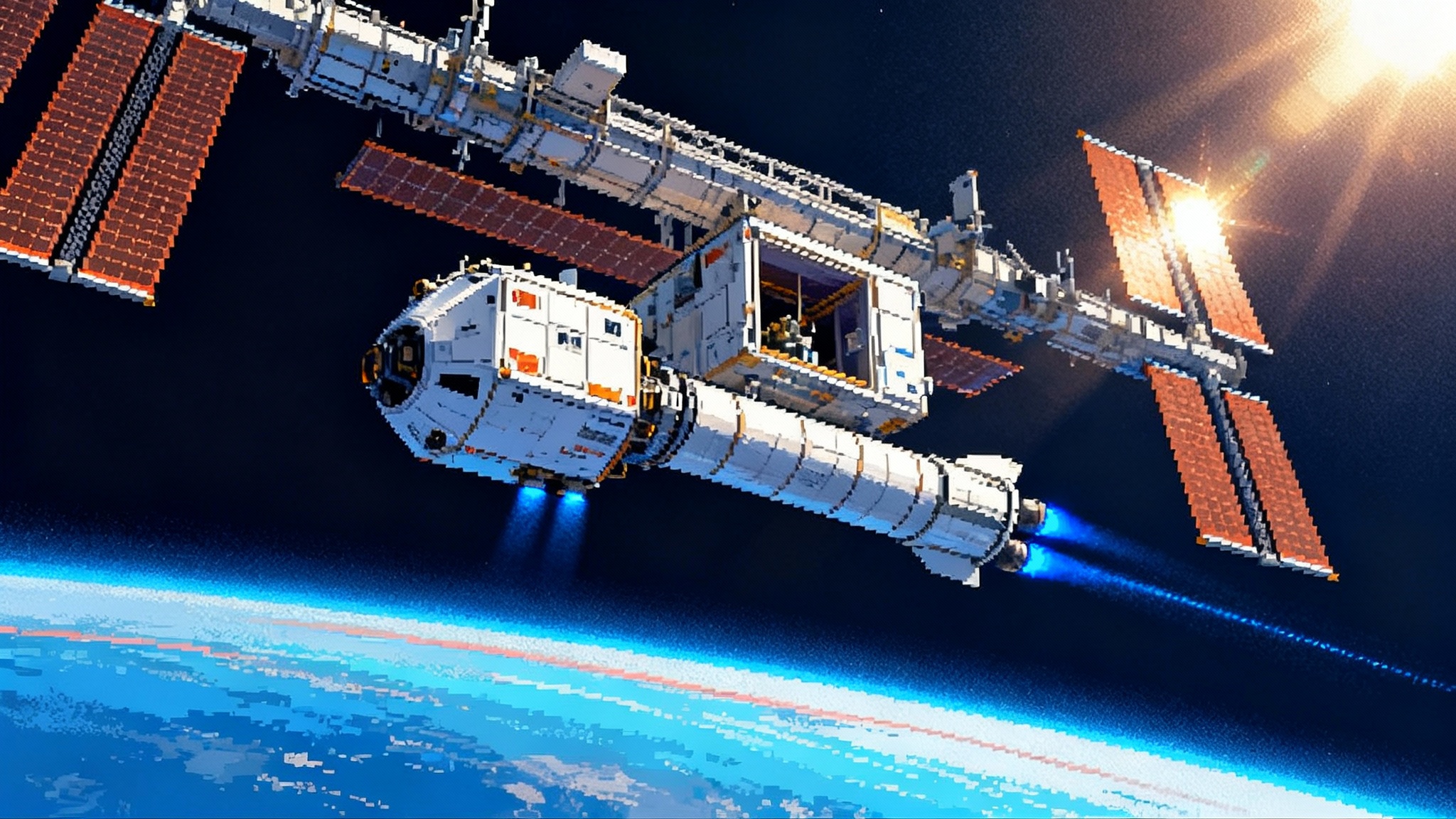

SpaceX just turned Dragon into an orbit‑maintenance tug. With a trunk mounted kit running on its own propellant, Dragon lifted the ISS and opened a new playbook for operations, cost, and governance through the end of the decade.

A small burn with big consequences

For the first time, a SpaceX Dragon arrived at the International Space Station carrying more than cargo and solar arrays in its trunk. It brought a reboost kit. On September 3, 2025, controllers commanded two trunk mounted Draco engines to fire for five minutes and three seconds, nudging the station’s perigee up by about a mile and leaving it in a 260.9 by 256.3 mile orbit. NASA called it the initial test of a new capability that will continue with a series of longer burns through the fall of 2025. The milestone is not just another thruster firing. It is a structural change in how the ISS stays aloft and who gets to keep it there. NASA’s post on the test burn has the numbers.

What exactly is in Dragon’s trunk

Think of Dragon’s trunk as a customizable utility bay. For this mission it carries a compact propulsion package that is completely independent from the capsule’s own propellant tanks and plumbing. The kit includes:

- Two Draco thrusters aligned to push along the docking axis and the ISS velocity vector.

- A dedicated set of storable hypergolic propellant tanks with their own helium pressurant.

- Valves, lines, and avionics that tie into Dragon’s command and telemetry without touching the capsule’s life critical propulsion loops.

NASA describes the kit as using existing Draco hardware and a separate propellant system to fuel two engines in the trunk, with periodic burns planned through the fall. That design choice is important. It quarantines risk. A leak or valve issue in the kit cannot propagate into the capsule systems that Dragon needs for safe undocking, deorbit, and splashdown. It also lets SpaceX tailor how much propellant to fly based on the reboost share NASA wants Dragon to shoulder on a particular mission. NASA laid out this plan in its mission overview for CRS 33, which also notes the first demonstration of ISS reboost capability back on November 8, 2024. NASA’s mission overview for CRS 33 is the reference.

How the trunk kit works

-

Propellants and thrusters: Draco thrusters are pressure fed bipropellant engines that burn a hypergolic pair in the hydrazine family with nitrogen tetroxide. Each Draco delivers roughly 400 newtons of thrust with high reliability and many restarts. The kit’s two Dracos are mounted in the trunk and pointed so their thrust passes cleanly down the docking axis.

-

Thrust line and loads: Dragon docks to an International Docking Adapter on NASA’s Harmony module, so the thrust line runs through the docking system into the U.S. segment structure. Reboost thrusting looks gentle, but the loads are real. The plan stays within the docking system’s axial load limits, and attitude control is coordinated so the control moment gyros keep torques tidy while the burners are lit.

-

Fire control: SpaceX commands the burns from the ground with NASA’s Flight Control Room in the loop. The kit’s avionics report pressures, temperatures, and thrust performance separately from the capsule’s own telemetry. If anything drifts out of limits, the kit can shut down without affecting Dragon’s primary systems.

-

Delta v: Two Dracos provide about 800 newtons combined. The ISS complex with a docked Dragon is near 450 metric tons, giving a tiny acceleration close to 0.0018 meters per second squared. Over 303 seconds, that is about 0.5 meters per second of delta v. At roughly 400 kilometers altitude, that is the right order of magnitude to lift perigee by around a kilometer without stressing hardware.

-

Plume and thermal: Thruster plumes need clear line of sight. Mounting in the trunk puts exhaust safely away from radiators, arrays, and sensors. Burn timing avoids thermal extremes and keeps star tracker fields clear of bright Earth limb or the Sun.

What the first burns tell us

Two data points matter: the November 8, 2024 demonstration and the September 3, 2025 trunk kit test.

-

The 2024 demo showed that Dragon could safely impart momentum to the ISS without the trunk kit. It proved the docking interface, Dragon’s control, and ISS attitude management could handle the choreography.

-

The 2025 trunk kit test added the dedicated hardware. The five minute burn produced a measurable orbit change and validated the independent propellant system. The duration and modest perigee lift match a cautious first light to keep margins high while verifying thermal, structural, and attitude behavior.

From a program standpoint, this proves that Dragon can contribute meaningful station keeping with hardware that does not consume the capsule’s own propellant reserves. It also proves that crews do not have to reconfigure anything inside. The entire sequence is run from the ground while the crew continues daily science and maintenance.

Why this changes day to day ISS operations

-

Fuel logistics: Until now, most altitude maintenance was done by Russian Progress vehicles, with Northrop Grumman’s Cygnus demonstrating and then providing limited reboost capability in recent years. Dragon’s kit adds a third path. Mission planners can now spread the annual drag budget across Progress, Cygnus, and Dragon.

-

Scheduling flexibility: Reboost windows must avoid spacewalks, dockings, robotics sessions, and vibration sensitive payloads. With another vehicle able to reboost, controllers can schedule shorter, more frequent burns that tuck into smaller gaps on the calendar and make debris avoidance maneuvers easier to plan.

-

Redundancy and fault tolerance: If one vehicle family is delayed or has a propellant constraint, the others can pick up the slack. That is exactly what you want when solar activity and atmospheric density spike.

-

Risk posture: The independence of the trunk kit removes a major coupling. A propellant or valve issue in the kit does not threaten Dragon’s ride home. If a kit fails in place, Dragon can still undock and the trunk will dispose safely on reentry.

-

Attitude and power housekeeping: Reboost burns slightly change how arrays track the Sun and how the control moment gyros handle momentum storage. With an extra provider, planners can choose burn times that reduce momentum dumps and keep power positive.

For broader context on how new launch cadence reshapes planning, see our New Glenn ESCAPADE preview.

The cost and geopolitics through the 2030s

This is not just an engineering footnote. It is a governance shift.

-

Autonomy: NASA intends to operate the ISS through at least 2030. Having U.S. visiting vehicles with certified reboost capability means the U.S. Operating Segment can maintain altitude even if Progress availability becomes constrained. That reduces a single point of dependence.

-

Economics: Progress flights bundle cargo and propulsion services. A trunk kit lets NASA buy a known amount of storable propellant and a few planned burns inside a commercial resupply mission it already procures. That is a cleaner marginal cost than building a dedicated propulsion module and a simpler contract line item than a separate tug.

-

Risk and insurance: Multiple reboost providers lower program risk. Lower risk often translates to smaller contingency reserves and fewer last minute replans when debris avoidance and drag spikes collide with the visiting vehicle schedule.

-

Signals to industry: NASA is telling providers that propulsion as a service is valuable. The kit is modest. The message is not. If a small, self contained package can carry a third of the station’s annual altitude keeping, the market for modular, visiting vehicle powered propulsion is real.

Engineering breakdown: numbers that matter

-

Thrust: about 800 newtons total from two Dracos. Small compared to a Progress main engine or Cygnus’s gimbaled engine, but more than enough for gentle, prograde station keeping when applied for several minutes.

-

Delta v per burn: the initial trunk kit burn’s order of magnitude was roughly 0.5 meters per second. Follow on burns can be longer and will layer in additional delta v until the kit’s tanks are spent.

-

Total contribution: NASA indicates that the 2025 campaign will include a series of longer burns. Combined, they are designed to shoulder a meaningful fraction of the annual drag budget while Dragon is docked. The remaining fraction will still be shared with Progress and Cygnus as needed.

-

Propellant: the kit flies storable hypergols compatible with Draco hardware. Hypergols ignite on contact, work across a wide temperature range, and tolerate many short pulses and restarts without turbomachinery.

-

Guidance and control: during reboost the ISS holds a steady attitude, the docking system remains loaded mostly in compression along its axis, and the control moment gyros trim residual torques. If the gyros approach momentum limits, planners schedule a momentum unload later using the Russian segment’s attitude thrusters.

What the next scheduled burns mean

NASA says a series of longer burns will run periodically through the fall of 2025 while this Dragon is docked. Operationally, that does three things at once:

-

It proves repeatability. One carefully choreographed burn can be a demo. Several burns across weeks begin to look like a service with predictable performance and consumables accounting.

-

It quantifies cost. With multiple burns you can track kilograms of propellant per meter per second of station delta v across different solar and atmospheric conditions. That lets managers compare the marginal cost of a Progress reboost, a Cygnus reboost, and a Dragon kit reboost on a common basis.

-

It exercises governance. Planning, commanding, and verifying a string of burns with U.S. hardware makes the U.S. segment operationally autonomous for basic orbit keeping.

How this informs future commercial stations

Look past the ISS and you see a template forming. Future commercial stations will pick from three propulsion patterns:

- Integrated: a built in service module with large tanks and thrusters. Simple but mass heavy.

- Visiting vehicle powered: short, periodic reboosts when a cargo ship is present. Lower mass on the station side and shifts propellant logistics to vehicles that are coming anyway.

- Plug in kits: attachable propulsion pallets that ride up inside or under resupply ships, then operate for months and are disposed on reentry.

The Dragon trunk kit is option three. It keeps thrust outside the pressurized volume, avoids recertifying the capsule, and fits within existing envelopes for launch and docking. For a parallel shift in surface operations, see our Moon landings 2025 lessons. For an example of how international programs can reshape architectures, read our Chang’e‑6 far side samples.

The pragmatic bottom line

- It works. A small, independent kit in a cargo trunk lifted the station’s perigee on command.

- It scales. More propellant and longer burns add more delta v that is easy to buy and plan as part of a cargo manifest.

- It changes incentives. With reboost no longer tied to one country’s vehicle, NASA can optimize for cost, schedule, and risk. That makes a 2030 plus lifetime more credible.

- It teaches the next generation. Commercial stations now have a live example of visiting vehicle powered reboost. Expect to see plug in propulsion pallets on design trades and RFPs.

What to watch next

- The cadence and length of the next burns through late 2025. Longer burns will show how much of the annual drag budget the kit can cover while Dragon is docked.

- Consumables accounting. Watch for NASA to publish or discuss total delta v delivered and propellant remaining when Dragon departs.

- Cross provider coordination. How often the program alternates between Dragon, Cygnus, and Progress for routine reboost will signal the target steady state.

- Structural margins and operations. As confidence grows, burns may inch longer while staying inside docking system load envelopes and crew timeline constraints.

The ISS has always been a partnership in steel and in paperwork. With Dragon’s trunk kit now contributing real impulse, that partnership gets a little more flexible. It is a small push that could keep the laboratory in its lane for the rest of the decade and teach industry how to build the next ones smarter.