Japan’s Ship Railgun Signals a New Cost-Per-Shot Era

Japan quietly took a railgun to sea and hit a real target ship. The milestone points to a future where magazine depth is measured in megawatts and machined slugs, not missile cells, reshaping the economics of naval defense.

The shot that changed the equation

In early summer 2025, Japan’s Acquisition, Technology and Logistics Agency quietly took a prototype electromagnetic railgun to sea aboard the test ship JS Asuka. In September 2025, the agency revealed that the gun had not only fired, but had engaged a real vessel used as a target during the trials. This matters less for the spectacle than for what it says about maturity. A railgun that can be aimed from a rolling deck, synchronized with ship sensors, and fired repeatedly without tearing itself apart marks a shift from laboratory curiosity to fleet candidate. Public reporting confirmed the shots and imagery from the trials, establishing the milestone as the first time a ship-mounted railgun fired at a real ship at sea (ATLA’s sea test confirmed).

The headlines were about firsts, but the subtext was cost and depth. Kinetic interceptors launched with electricity promise per-shot costs measured in thousands of dollars instead of hundreds of thousands or millions. They also promise to replace the fragile idea of a magazine filled with missiles that can run out in one tense evening with the sturdier idea of a magazine that is the ship’s power system and an inventory of inert slugs.

Why now: pulsed power meets GaN-class switching

Electromagnetic railguns have always been a power problem first and a metallurgy problem second. The shot begins with a rapid charge of an intermediate energy store, then a very short, very intense discharge through the rails. Three enabling pieces have matured enough for sea trials to look practical this decade:

-

High energy density pulse capacitors. Modern pulse capacitors store more energy per kilogram than designs from a decade ago and can be arranged in modular banks. That makes it possible to tuck meaningful megajoule capacity into hull spaces that used to carry auxiliary equipment. Japan’s test gear visibly used containerized modules, a clue that the charging and discharge banks are now truly modular rather than bespoke science projects.

-

Solid-state switches that can take a beating. The move from older silicon devices to silicon carbide and gallium nitride has changed the switching game. Gallium nitride devices turn on and off faster with lower losses, which improves overall efficiency and shot-to-shot reliability. Silicon carbide prefers higher voltages and can handle heat better. In a practical ship system, you mix and match. GaN drives the fast edge for precise pulse shaping; SiC handles medium voltage stages and helps keep the thermal budget under control.

-

Smarter pulse-forming controls. A railgun’s pulse is not a simple on-off blast. It is a shaped surge that must keep the armature in the sweet zone between blowoff and stall, while preventing catastrophic rail erosion. Advances in digital control and measurement make that shaping more repeatable. On Asuka’s deck photos, you can spot the supporting cast: muzzle velocity radar, electro-optical aids, and cabling that betrays segmented banks. These are not gimmicks; they are the instrumentation that keeps currents and wear within limits.

Think of the system like a rechargeable power tool scaled up to skyscraper size. The ship’s turbines or diesels trickle energy into a rack of batteries and capacitors. Solid-state switches act as the tool’s trigger and governor, delivering an exact burst when commanded. Better switches and better capacitors mean you can squeeze more useful work out of each charge without overshooting and cracking the tool.

What magazine depth means when your magazine is power

For a missile ship, magazine depth is a count of cells. When those cells are gone, the ship is done until it reloads. For a railgun ship, magazine depth is a function of available electrical power, the recharge rate of the pulse bank, and the physical stack of inert projectiles. That is a different kind of math.

A notional medium-caliber railgun firing a few megajoules per shot may need on the order of megawatts of charging power for a modest rate of fire. On an escort with 8 to 12 megawatts of service power in reserve, the ship can allocate a few megawatts to keep a pulse bank topped off while still keeping sensors, pumps, and hotel loads alive. If it must surge, it can pause other loads and rapidly recharge. The constraining factors become thermal management, rail wear, and fire-control dwell time, not the count of tubes on day one of a deployment.

The cost curve tilts just as importantly. A missile interceptor involves seekers, actuators, and a rocket motor. It is complex by design and pricey by necessity. A railgun shot is a slug and a pulse of electricity. Even with a smart projectile or a sabot and sabot discard, unit cost remains closer to industrial machining than aerospace avionics. In a world where air and missile raid sizes are growing faster than defense budgets, that difference does not just save money; it makes defense sustainable night after night. For context on how strike inventories are shifting, see the discussion of JASSM-XR and lower-cost missiles.

What Japan proved at sea

Japan did not prove that railguns are ready to replace missiles. It proved that the hardest integration hurdle is now manageable. The gun fired while coupled to a ship’s motion and a ship’s sensors. The fire-control stack kept up. Instrumentation captured data for improvements. No one test answers questions about barrel life, efficiency, or the lethality envelope against complex threats. But a sea trial that hits a real target ship says this is past the point of speculation.

Japan has been laying groundwork for this moment for years. The prototype lineage has included a 40 millimeter barrel and multi-megajoule energy storage, with demonstrated projectile velocities in the hypersonic range. Industry that matters to pulsed power and rails sits close to home. Japan Steel Works has gunmaking pedigree. Mitsubishi Heavy Industries integrates complex ship systems. Electronics suppliers like ROHM, Toshiba, Renesas, and Murata make the switches and capacitors that turn equations into hardware. That concentration shortens the time between lessons learned on Asuka and a version that fits under a stealthy gunhouse on an operational escort.

Integration paths: power modules, fire control, ship classes

Power modules and placement. Practical railguns will live in modular racks that combine chargers, capacitors, and switchgear. These modules should be sized to standard shipboard handling envelopes so they can be moved and replaced without cutting steel. Designers will likely place the pulse banks as close to the mount as possible to minimize resistive losses, then route cooling and service power from existing trunks. Machinery spaces that once hosted auxiliary boilers or legacy converters become prime real estate for power modules. The most successful designs will be those that can scale from a few megajoules per shot for drone and small missile defense to higher energy for anti-ship strikes by adding racks rather than redesigning the ship.

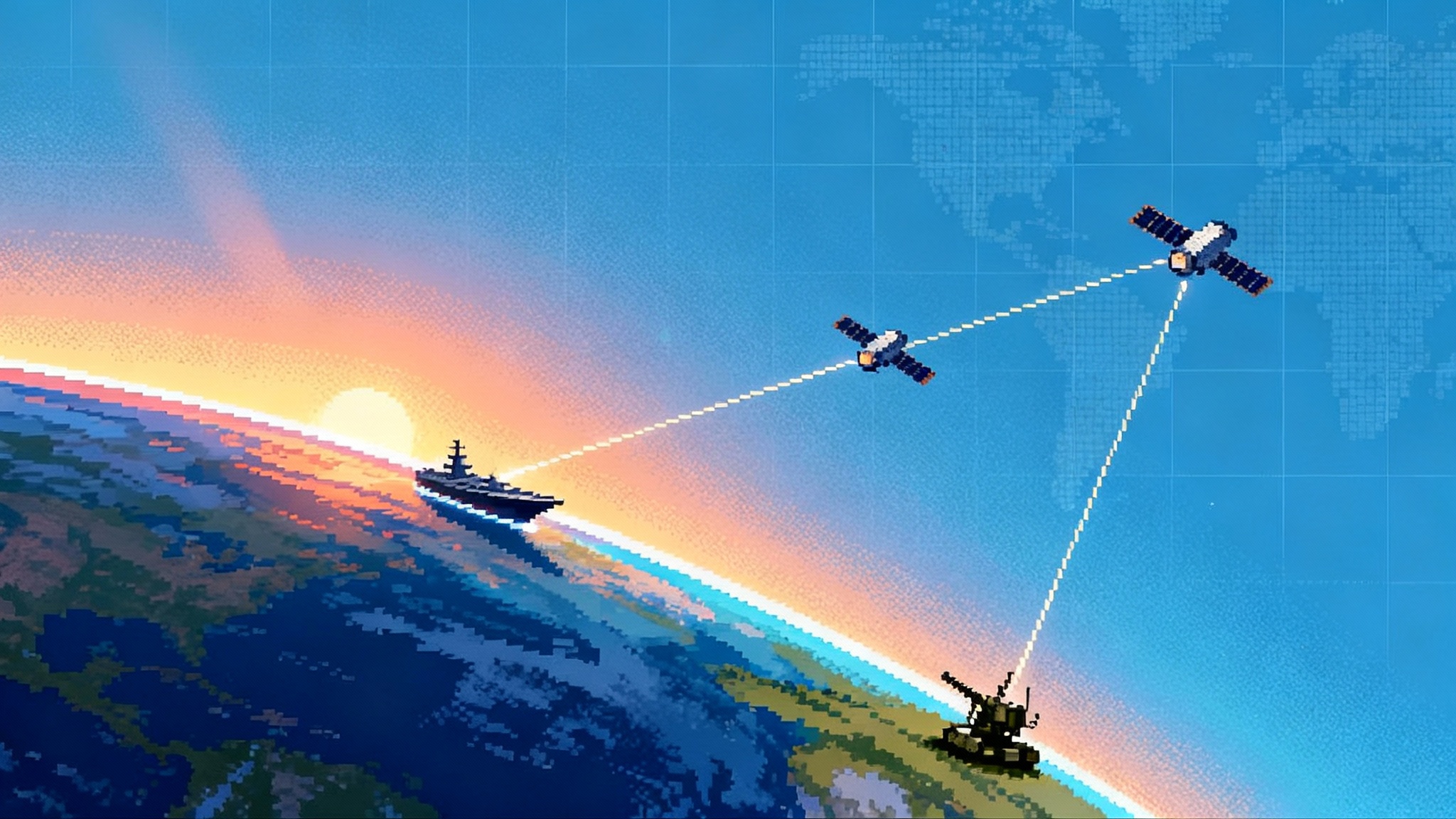

Fire control and the kill chain. A railgun shot must be cued, assigned, and timed with more precision than a shell from a powder gun. The kill chain will lean on the same radar and combat system used to assign surface-to-air missiles, with a few extra twist knobs. Muzzle velocity radar calibrates each barrel’s current state. Electro-optical sensors and compact tracking radars validate impacts and refine aim point for follow-on shots. Data must flow quickly enough to allow a short burst of shots to walk into a maneuvering target. Networked sensing, including space-based tracking akin to the SDA LEO kill web system, will further tighten cueing and engagement windows. That means a deep integration with Aegis or its local equivalent rather than a standalone console bolted to a bulkhead.

Ship classes and probable first adopters. In Japan, the pragmatic path runs through three hull types:

- The Mogami-class frigate, which already emphasizes modular payloads and reduced crew. Its efficient power plant and open architecture make it a likely early host for a low-to-medium energy railgun intended for drone and slow missile defense.

- The Maya and Atago classes of Aegis destroyers, which have the power margins and combat system integration to employ a higher energy variant and to support the sensor and computing demands that go with it.

- The Akizuki and Asahi classes, where a containerized or deckhouse-mounted demonstrator could backfit without a multi-year yard period.

Shore batteries are not glamorous, but they are smart proving grounds. A land-based railgun at a strait or port defense site lets crews learn the rhythms of charging, cooling, and barrel maintenance while the fleet waits for hulls to cycle through modernization.

How the cost math plays out at sea

Consider a night where a surface action group faces a mixed raid of drones and subsonic cruise missiles. With missiles alone, the group’s commander must balance certainty of kill against the finite number of cells remaining for the next night. Interceptors with seekers and rocket motors cost hundreds of thousands to millions per round, and long shipping queues make reloads uncertain. With a railgun in the mix, the commander can assign the railgun to drones, to leakers inside the last engagement zone, and to hard-kill shots that help a laser’s soft-kill attempts. Each railgun shot consumes electricity and a machined slug. The per-shot cost is small compared to a guided missile. That change allows commanders to conserve high-end interceptors for the threats that truly demand them and still keep up with the volume of raids.

The other cost is opportunity. Charging a pulse bank consumes power that might otherwise drive a radar or a combat system surge. That is why pulse management and shot doctrine matter. Trained operators will learn to stagger charges, pre-charge during quiet windows, and hold partial charges for snap shots. The design goal is simple: give the commander knobs to trade power, heat, and magazine depth without ever emptying the tank.

The engineering headwinds that still count

Barrel life. Each shot drags an armature down the rails with colossal current. Wear is not a small problem. Expect designs that use replaceable liners, segmented rails, and coatings that trade small efficiency losses for longer life. The maintenance concept will look like modern naval gun upkeep, just with more electrical checks and fewer powder hoists.

Thermal management. Heat is the silent killer of rate of fire. Designers must overbuild cooling loops and make sure hot spots can be reached and serviced at sea. What looks compact in a lab must breathe in a machinery space.

System efficiency. Converting ship power to muzzle energy involves losses at each stage. Better switches, better conductors, and tighter pulse shaping are not features; they are the difference between a practical weapon and a science fair. Expect sea trials to spend as much time measuring voltages, temperatures, and timing jitter as measuring range.

Lethality across the envelope. Slugs that are perfect for drones may not be optimal against hardened missiles or surface targets. Guidance that makes sense for one mission may add cost and complexity for little gain in another. A mature program will field a family of projectiles that share sabot and interface geometry but customize nose shape, guidance, and fusing for the job.

How railguns fit with lasers and missiles

This is not a winner take all fight. Lasers excel at dazzling, burning, and attriting low-cost threats when the air is clear and the geometry is right, as illustrated by the Leonidas 49 drone swarm. Missiles reach far and bring seekers to complex, maneuvering targets. Railguns add the brute-force middle layer. They hit hard inside the last tens of kilometers, they scale by adding power modules and racks of slugs, and they free expensive interceptors for what only missiles can do. The U.S. Navy’s program pause in 2021 reflected reasonable concerns about barrel life and integration, and Congress later focused oversight on lasers while archiving prior railgun work for reference (CRS synopsis of the pivot). Japan’s sea test does not erase those concerns, but it does show how far the enabling tech has moved.

What the U.S. and allies should accelerate next

- Standardize power modules. Publish open interface standards for pulsed power racks so navies can buy chargers, capacitors, and switchgear from multiple vendors. Do the same for health monitoring so a destroyer’s maintenance console can see the railgun like any other plant equipment.

- Fund joint GaN and SiC switching. Back high-current, high-repetition switches. The return on investment shows up across railguns, high power microwave systems, and next-generation radars. Prioritize thermal design and lifetime under shock and salt fog.

- Build a common projectile family. Define a baseline sabot, guidance interface, and data link that lets slugs be tailored to mission without changing the gun. Encourage Japan, the United States, the United Kingdom, and Australia to share range time and lethality data.

- Create shore-based railgun sites. Put batteries at straits and ports where long dwell shots against drones and slow missiles have high payoff. Use those sites to train crews and burn in hardware while ships cycle through upgrades.

- Make combat system integration first class. Give Aegis and other combat systems real-time hooks for pulse state, barrel state, and predicted time to next shot, so the system can assign railgun shots like any other effector.

- Treat barrel life as an industrial problem. Fund rail materials, liners, and coatings the way navies fund propellant research for powder guns. Reward designs that make barrels fast to swap and easy to diagnose at sea.

- Test railgun plus laser playbooks. Practice layered engagements where a laser blinds and slows, then a railgun finishes. Write doctrine that conserves power and mass across the entire self-defense stack.

The near horizon

Japan’s shot at sea is not a silver bullet, but it is a line crossed. Pulsed power no longer looks like an anchor that keeps railguns in the pier-side lab. GaN-class electronics have changed how cleanly, quickly, and repeatably a ship can throw a megajoule. The practical questions left are the kind that yield to engineering discipline and time at sea: how long rails last, how fast crews can swap modules, how integration looks on a 5,000 ton frigate instead of an instrumented test ship.

If the next two years bring a railgun under a proper gunhouse on a Mogami or an Aegis destroyer, the conversation will shift from whether this works to how best to use it. When that happens, the price and pace of defense will bend. Commanders will plan around power budgets rather than cell counts. Navies will replenish slugs by the pallet rather than fly in rare interceptors. And adversaries will face a defender that can keep shooting after the first wave, and the next one, and the one after that. That is what a new cost-per-shot era looks like in practice.

The lesson is simple and concrete: keep pushing pulsed power and integration, not as a science project but as a ship system. The countries that make that mental shift fastest will own the next decade of naval defense.