Commercial Moon Landings Grow Up in 2025: Blue Ghost and IM-2

Two March 2025 touchdowns turned promise into process. Firefly’s Blue Ghost executed a clean surface sprint, while Intuitive Machines’ IM-2 reached the south polar highlands and revealed hard lessons in stability, power, and polar lighting.

March 2025 reset the lunar playbook

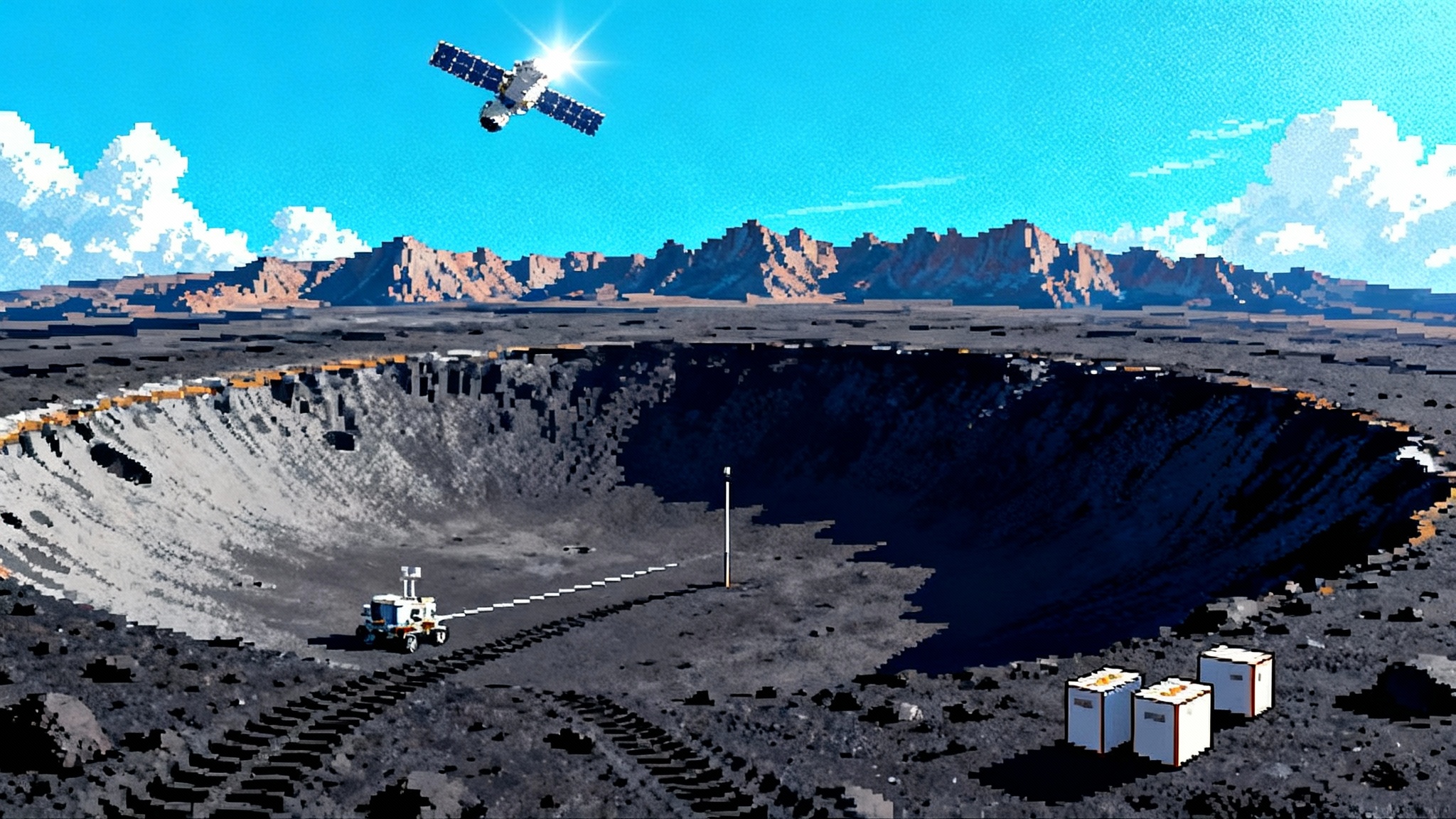

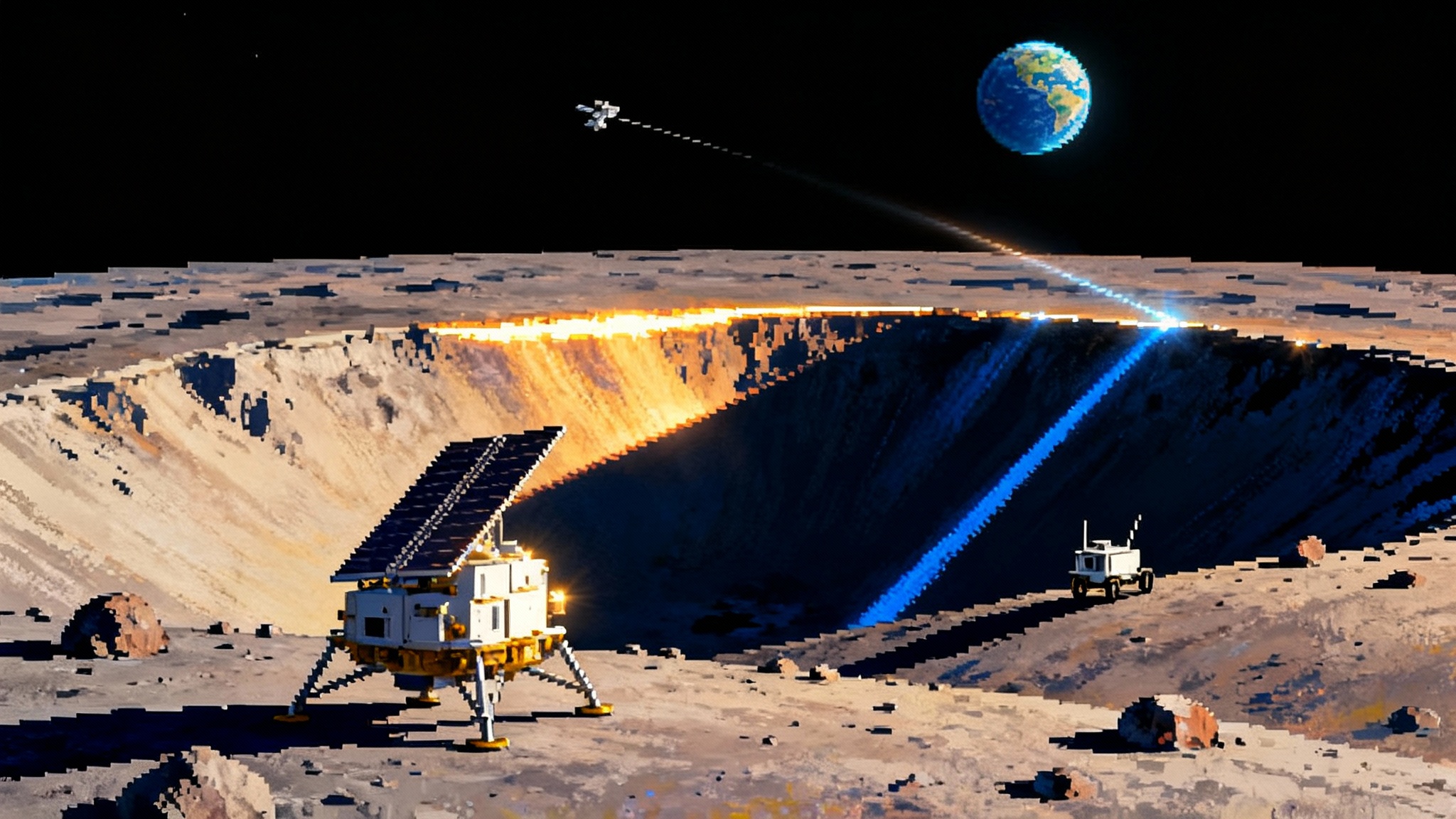

Two landings, four days apart, turned the promise of commercial lunar delivery into a working blueprint with clear to‑do items. On March 2, 2025, Firefly Aerospace’s Blue Ghost touched down on the Moon’s near side and quickly moved into payload operations, proving that a private lander can arrive, work, and close out a mission on schedule. On March 6, Intuitive Machines’ IM‑2 Athena reached the Mons Mouton region near the lunar south pole but came to rest on its side inside a crater, cutting operations short. NASA confirmed the landing and the early end of mission after teams squeezed in initial runs of the PRIME‑1 ice prospecting suite. NASA’s post‑landing update captured the bittersweet moment: a historic polar arrival that immediately illuminated what must improve for the next wave.

If 2024’s IM‑1 showed that a private lander could survive the trip and reach the surface, March 2025 matured the idea. Blue Ghost delivered a clean, methodical surface day. IM‑2 aimed for the most scientifically valuable real estate on the Moon, where the terrain and lighting punish tall, top‑heavy machines. Together they reset expectations for Artemis‑era exploration: move faster, aim harder, and design for the pole’s peculiar physics.

What worked

1) Navigation that leans on multiple senses

Blue Ghost demonstrated that lunar navigation can start to look more like modern aviation than deep‑space dead reckoning. The mission recorded the first use of Global Navigation Satellite System signals on the lunar surface, leveraging faint GPS and Galileo transmissions as an additional, autonomous source of position. That milestone, documented by NASA’s Space Communications and Navigation program, suggests future landers can blend star trackers, optical terrain matching, Doppler radar, and weak but usable Earth‑origin signals to keep their bearings from cruise to touchdown. NASA’s GNSS confirmation matters because autonomy scales. Every algorithm that reduces ground intervention cuts timeline friction and increases the number of tasks a small team can operate in parallel.

Think of it like adding extra landmarks to a pilot’s chart. A single lighthouse helps, but a web of beacons lets you fly tighter patterns in bad weather. On the Moon, where communication light‑time is seconds, each independent cue is time back in the operations bank.

2) Communications that prioritize usable data early

Both missions showed a disciplined focus on the first hours after landing. Blue Ghost moved quickly to commission payloads and downlink the most perishable data. IM‑2’s team, facing a lander on its side in a hostile crater, accelerated PRIME‑1’s initial sequences to capture scans before batteries chilled past the point of recovery. This mindset is the right one for commercial cadence: assume every minute on the surface is precious, build playbooks around short bursts of high‑value operations, and plan to close experiments in that first shift. This emphasis on high‑value bits echoes the trajectory highlighted in deep‑space laser links finale.

A practical example: prioritize low‑latency thumbnails and quick‑look science over large, lossless data products on day one, then backfill when the system proves it can survive to day two. The habit forces payload teams to design for progressive disclosure of value, which is exactly how iterative lunar work will scale.

3) Rapid surface ops with pre‑baked autonomy

Where Blue Ghost shined was the speed from landing to action. Preplanned sequences, straightforward mechanisms, and conservative surface timelines kept complexity in check. This is the approach that enables multiple flights per year. Treat the first lunar day like a sprint, with daily goals that can stand on their own if the mission ends early.

What failed, and why

1) Lander stability in sloped, blocky terrain

IM‑2’s tip‑over is the clearest signal yet that the south pole punishes tall landers. Low Sun, long shadows, and local slopes can trick hazard cameras and make footpad placement uncertain. A slender vehicle with a high center of gravity is like a loaded pickup parked on a gravel embankment. One footpad hits a hidden rock, another sinks into porous regolith, and the torque at touchdown does the rest.

Contributing factors likely included small boulders, soft soil layers, and limited ability to sense and reject micro‑hazards in the last tens of meters. The lesson is not subtle: design squat, land wider, and sense finer. The pole will not cut you any slack. For broader lunar context on where the volatiles and rocks may guide missions next, see Chang'e‑6 lunar samples.

2) Power and thermal in shadowed craters

Athena’s resting pose inside a crater put its solar panels at the wrong angle and its radiators in a deep freeze. Permanently or seasonally shadowed regions behave like open cryogenic freezers. The airless environment offers no convective warmth, so anything that is not sunlit plummets toward the background temperature of space. Once batteries drop below operating thresholds, heaters and transmitters cannot help without new power. The mission’s brief life after landing is a direct reminder that power margin and heater placement must be sized specifically for polar lighting geometry, not for equatorial missions.

Even daytime surface work at the pole is tricky. Sunlight skims the horizon, which means small rocks cast long, cold shadows. Instruments need thermal tents, landers need panel tilts or deployable booms that reach into sunlight, and cables must be routed for both hot and cold extremes.

The 12 to 24 month playbook

The next two years can convert these lessons into a durable operating model. Here is the concrete plan that NASA Commercial Lunar Payload Services and its contractors can execute now.

1) Tougher south‑pole targeting, staged by difficulty

- Define graded landing zones by slope, boulder density, and Sun elevation. Start with zones that offer several hours of line‑of‑sight to the Sun each day and gentle grades, then move stepwise toward sites that flirt with permanent shadow.

- Tie milestone payments to difficulty tiers, not just landing. Paying more for harder targets will pull hazard‑avoidance tech and polar‑specific power systems forward.

- Require mission designs to demonstrate a plan for the last 500 meters. That is where most of the polar risk lives.

2) Hazard‑avoidance upgrades that see and decide faster

- Add a flash lidar or scanning lidar to resolve ankle‑high rocks and subtle micro‑ridges in the final descent. Optical terrain relative navigation is good for the hundred‑meter scale. The last step needs range data.

- Train descent classifiers on polar lighting using hardware‑in‑the‑loop labs. Simulated sunlight at grazing angles, high dynamic range cameras, and regolith bins with embedded boulders will expose perception failures before flight.

- Precompute divert options for the last 50 meters, with fuel reserves explicitly protected in guidance budgets. If the vehicle cannot step sideways to avoid a rock the size of a suitcase, it should not fly a polar profile.

3) Lower center‑of‑gravity lander designs

- Shorten the bus, widen the legs, and lengthen the crushable stroke in landing gear. A lower belly, soft legs, and wide stance reduce tip‑in torque at first contact.

- Introduce deployable outriggers or footpad skirts that increase effective area without heavy legs. Think of a backcountry snowshoe that spreads load on soft snow.

- Package tall payloads sideways, then hinge them upright after landing. This keeps the mass low for touchdown and only raises it once the vehicle is stable.

4) Resource‑prospecting payloads that trade depth for certainty

- Pair drills with down‑looking thermal and neutron instruments to target the most promising patches before cutting. A shallow scout pass can prevent wasting drill time in dry soil.

- Use short‑throw hoppers and micro‑rovers to dip into a shadowed swale and pop back into sunlight. A 200‑meter hop can sample a thermal boundary without risking the lander.

- Plan for sample heating, gas analysis, and repeat scans in the first shift. If the lander fails on night one, the science still tells a complete story about volatiles and soil structure.

5) A polar relay network, small and soon

- Seed two to four small relay satellites in frozen polar orbits with line of sight into key craters. The goal is not a perfect telecom constellation, it is a dependable link during the first lunar day.

- Equip relays with store‑and‑forward for bursty science and simple ranging beacons for last‑mile navigation. Even a basic timing signal helps descent solutions converge.

- Cross‑support with existing Earth networks to reduce ground staffing. The right software can let one shift of operators run multiple landers and relays with playbook automation.

6) Faster CLPS cadence with deliberate risk

- Fly more, smaller missions. Monthly or bimonthly launches create a learning loop that no paper review can match. When a design choice is wrong, you fix it on the next vehicle, not in two years.

- Adopt block upgrades. Freeze a baseline lander for three to four flights, then roll in a batch of changes together. Operators learn repeatable behavior while engineers move the design in visible steps.

- Buy landing opportunities in pairs. Send a pathfinder to map hazards and prove the power geometry, then follow within one lunar day with the primary science lander.

The point is not to court failure. It is to lower the cost of learning so the south pole becomes routine by 2027. Iteration is the only way to get enough at‑bats to master a place where sunlight skims the rim and the ground tries to push you over.

How March 2025 reshapes Artemis operations

Artemis crews will benefit directly from what these missions taught. The south polar plateau is a logistical challenge wrapped in scientific promise. To turn it into a worksite where astronauts can safely move, drill, and deploy infrastructure, commercial landers must master three things.

-

Consistent, precise landings within walking or rover range of targeted deposits. This demands the hazard sensors and divert logic listed above, plus descent profiles that protect fuel for last‑second choices.

-

Robust power through the polar day. That means panels that tilt or extend to catch low Sun, batteries with thermal conditioning that matches the actual crater microclimate, and heater placement validated in polar‑lighting labs, not equatorial stand‑ins.

-

Stable platforms with low centers of gravity. A tipped vehicle is not just a short mission, it is a hazard. Crews and robots cannot rely on landers that fall over when the soil surprises them. Squat designs and wider legs need to be de‑risked now.

For NASA, the near‑term policy shift is clear. Reward missions that take on harder polar sites, not just any soft landing. Fund polar relay pathfinders that provide two‑way links into shadow. Prioritize instruments that tell us where ice actually sits at decimeter scales, because that is the resolution that matters for boots and drills. These decisions tie into the broader logistics chain that will connect to Gateway, as explored in HTV‑X1 sets sights on Gateway.

For industry, the engineering shift is equally clear. Move mass down, move sensors forward, and move operations earlier in the surface day. Build payloads that produce a usable result in the first shift, then improve it if the vehicle survives to shift two.

A pragmatic acceleration to 2027

Blue Ghost showed that a commercial lander can arrive, work, and wrap up on time. IM‑2 showed that the polar rules are different and unforgiving. Together they point to a strategy that is both faster and safer. Fly often, accept bounded risk, and route every lesson into the next design without waiting for perfect answers.

By early 2026, we should be seeing squat landers putting down on graded sites near the pole, running playbooks that front‑load science, and talking to small polar relays overhead. By 2027, the community can be operating on tougher slopes, taking short hops into the cold, and delivering resource maps at the meter scale. That is what sustainable polar operations actually looks like: a tempo that turns unknowns into routines.

The Moon did not change in March. We did. Two landings, one textbook and one humbling, gave us the new rules of exploration.