HTV-X1 Rewires ISS Supply Lines and Sets Sights on Gateway

Japan’s next‑gen cargo ship launched on H3, delivered on schedule, and keeps flying for months as a testbed—tightening the ISS supply chain today and training for Gateway tomorrow.

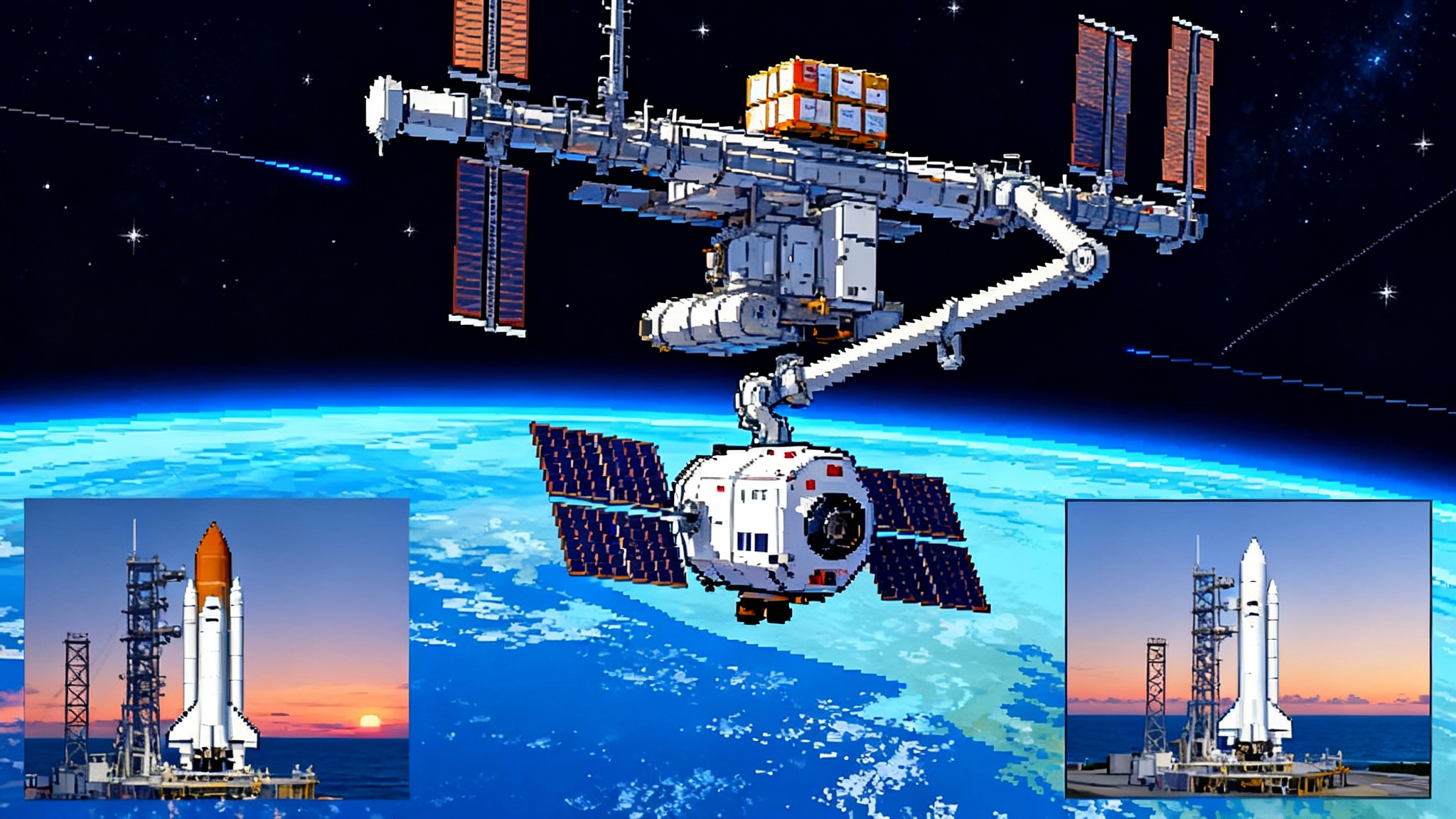

The cargo ship that arrived right on time

On October 26, 2025 in Japan Standard Time, a bright column of flame lifted Japan’s first HTV-X cargo ship into orbit aboard an H3 rocket from Tanegashima. Four days later, on October 30 in Japan Standard Time, the spacecraft was captured by Canadarm2 and berthed to the Harmony module. The grab was executed from inside the station by Japan Aerospace Exploration Agency astronaut Kimiya Yui, closing out a clean first approach for a brand new vehicle. For a milestone this precise, the source is not gossip. It is official. See the timeline in JAXA’s berthing report.

The quick facts matter because HTV-X1 is not just another supply run. It is the first member of a new logistics class designed by the Japan Aerospace Exploration Agency and built with industry partners to do two jobs at once. First, upgrade the flow of cargo to the International Space Station. Second, train the systems and operations that will push the same architecture outward to the lunar Gateway and to commercial stations. That is a big claim, so let us unpack what is actually new, how it works, and why it accelerates the path from low Earth orbit to the Moon’s neighborhood today rather than in some distant 2030s future.

The two-minute drill before liftoff

If you run a lab that ships fragile experiments, you know the dread of a long countdown. In the old flow for Japan’s previous cargo ship Kounotori, the final chance to load time sensitive items came roughly 80 hours before launch. HTV-X shrinks that window to as little as 24 hours. Think of it as a cold chain courier arriving late the night before the truck leaves, not three days earlier. That single change reduces spoilage risk, allows more flexible ground schedules, and lets scientists finish last minute prep for biological samples without blowing the manifest.

A shorter late-load window also helps operations managers. The closer you can get cargo acceptance to the launch clock, the fewer moving parts you must freeze for days in advance. That makes manifests easier to replan when weather pushes the date. For programs that live and die by coordination among multiple agencies, less time locked in concrete is a quiet revolution. This focus on fast turns mirrors the tempo seen in Starship’s 2025 pivot to payloads.

A powered cold chain in flight

Kounotori was a workhorse, but it could not supply power to cargo during transit. HTV-X can. That means refrigerators and powered experiment racks ride to orbit while actually running. The difference is like shipping vaccines in a humming medical fridge, not a box of ice packs. For life sciences, food quality checks, and time critical materials for the Japanese Experiment Module, it turns the flight from a stressful gap into a controlled part of the protocol.

Why this matters today: Space stations have become on orbit factories for bio-tech, advanced materials, and microgravity processes. Many of those require temperature control to preserve viability or to keep growth at a target rate. With power flowing to payloads from the moment the fairing opens to the moment hatches swing wide, HTV-X makes the whole end to end experiment more predictable and reduces the number of workarounds crews must do after arrival.

Bigger and more flexible cargo

HTV-X increases useful volume and makes it simpler to use by adopting standard rack structures in the pressurized module and a stronger mount for external payloads on the top of the service module. The pressurized section accepts a denser arrangement of racks than before. The unpressurized section can host bulky items that ride outside, from platforms to replaceable components.

Two effects follow. First, crews can unpack like warehouse staff pulling from a well labeled pallet rack rather than a mixed crate. Second, project teams can plan larger one piece deliveries and avoid expensive multi flight assembly. A single mission that carries both inside and outside cargo also reduces coordination costs with robotics teams and with spacewalk schedulers.

Berthing now, docking later

If you watch video of the arrival, you see a familiar choreography. HTV-X holds, approaches, and is then captured by Canadarm2 for berthing to a Common Berthing Mechanism port. That is the safest option for a maiden flight and it fits the way the International Space Station has treated many cargo vehicles for years.

What changes next is the path to autonomous docking. Japan’s roadmap includes demonstrations of an International Docking System Standard compatible hardware set so that future flights can dock on their own when the station is ready to receive that capability. Docking removes the need for a robotic capture window and frees up crew time. It is also required for destinations that may be uncrewed for long stretches, which is the case for lunar Gateway operations.

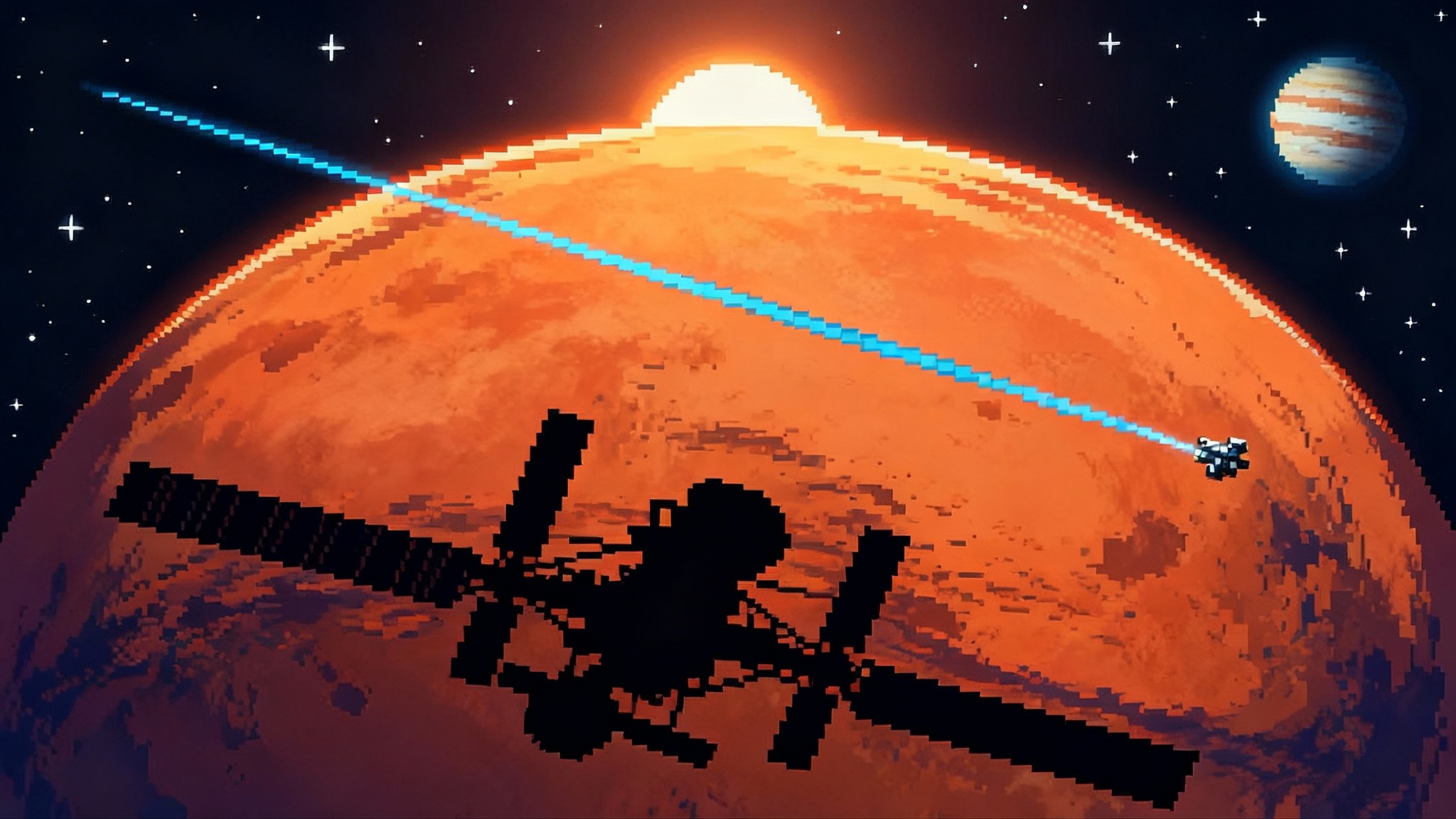

Months of post station free flight

Here is the feature that most obviously points past the International Space Station. After unberthing, HTV-X is designed to keep operating as an independent spacecraft for months. In the first mission, the plan calls for a three month free flight technology demonstration. The platform is set up to test deployable structures, power technologies, advanced antennas, and to release a small satellite from a higher orbit than the station. Those details are not academic. They are exactly the kinds of systems that a future cislunar logistics craft must carry when it acts as both courier and testbed. Europe’s Proba-3 artificial eclipses in orbit show how free flyers can retire risk for precision formations and novel hardware.

Keeping the service module healthy for months after the primary cargo job is not trivial. It demands robust power margins, high reliability thermal control, and a communications system that can support long dwell times without constant human babysitting. The payoff is twofold. Users gain an in space lab for risky demos without paying for a dedicated spacecraft. And the vehicle team gathers real data on wear, power budgets, and autonomy that feeds directly into deep space versions.

Why it upgrades today’s supply chain

Viewed through a logistics lens, HTV-X1 gives ground teams three new levers.

- Time to launch: Late loading to 24 hours cuts buffer inventory and schedule risk.

- Condition on arrival: Powered cargo means fewer recovery procedures and faster transfer from hatch to operation.

- Utilization after delivery: Months of free flight turn a single mission into two, stretching the value of each launch slot.

Those levers translate into fewer scrubs that force cargo swaps, fewer waste streams from spoiled samples, and a better return on the most precious resource of all in orbit, crew hours. When you add in the ability to combine interior racks and exterior payloads on one flight, you get a cleaner manifest with fewer hidden dependencies.

The path from HTV-X to HTV-XG

The bridge to the Moon is not marketing. The United States and its partners are building a small space station in lunar orbit called Gateway to support Artemis missions. As part of that program, Japan committed to deliver an evolved logistics vehicle, known as HTV-XG, for a Gateway resupply mission no later than 2030. That pledge sits on NASA’s official pages. Read it on NASA’s Gateway contributions page.

The technical delta from International Space Station flights to a Gateway run is significant but manageable. The hardware must trade berthing systems for an autonomous International Docking System Standard interface. The mission profile must shift from a few hundred kilometers above Earth to a near rectilinear halo orbit around the Moon. That requires higher performance propulsion and tighter navigation. Communications must ride deep space networks instead of the near Earth links used today. Radiation shielding and consumables must be planned for longer cruise times and for an outpost that is often uncrewed. All of those challenges are addressable through the same modular service module that powers HTV-X1 today. In other words, the engineering scaffolding is already in flight.

What it means for commercial stations

Operators planning private stations in low Earth orbit want quick turns on cargo, reliability, and cost control. HTV-X checks each box in ways that scale. Late load is a cost control tool because it cuts the waste of freezing manifests too early. Powered cargo enables new product lines in orbit, from pharmaceuticals to food science, because companies can align the cold chain with Earth standards. The free flight phase creates a shared orbital test range so that suppliers of deployable antennas, sensors, and even small satellite dispensers can validate their hardware without chartering a full mission. You can see the same industrial pattern in our look at industry fast track to the 2030s.

The commercial angle extends back down the supply chain in Japan. Mitsubishi Heavy Industries builds the H3 and is involved in the vehicle hardware. Japanese electronics and materials firms gain a platform to trial components off Earth. That ecosystem effect matters because it builds industrial depth ahead of the bigger prize, regular cislunar logistics.

Comparison with other vehicles

It is helpful to see HTV-X in context. Russia’s Progress is reliable, but it does not provide a powered cold chain in the same way and it cannot perform long post mission free flight as a demo platform. Northrop Grumman’s Cygnus can carry significant pressurized cargo and uses berthing, but it does not offer the same late load and extended demo phase as a baseline offering. SpaceX’s Dragon brings cargo back to Earth, which is valuable for return samples, yet it does not combine return with a months long free flight test mission after departure. HTV-X slots into this mix by optimizing prelaunch flexibility, in flight power, and post mission utility.

None of this is a knock on any other system. It is a recognition that the station needs a diverse fleet. HTV-X puts Japan in the role of the flexible operator that can run a cargo mission and then keep flying as a test platform. That niche complements return capable and high cadence services already on the manifest.

The network effect from low Earth orbit to lunar orbit

Logistics only become powerful when they form a network. With HTV-X1 berthed and working, a path emerges:

- Near term: repeat HTV-X flights build muscle memory for late load, powered payloads, and mixed interior exterior missions.

- Mid term: demonstrate autonomous docking hardware and procedures, so that the vehicle can service uncrewed destinations reliably.

- Cislunar: field HTV-XG with deep space propulsion and communications to haul cargo to Gateway on schedules aligned with Artemis surface sorties.

Run that play a few times, and you have the beginnings of a freight network where low Earth orbit stations, free flying testbeds, and a lunar outpost share hardware, operations staff, and suppliers. The benefit is not abstract. It shows up as faster integration of new tech in space and fewer one off spacecraft designed for single use.

What to watch next

- How well the powered cold chain performs door to hatch. Expect users to report on sample viability and on the time from arrival to experiment start.

- The mix of pressurized and unpressurized cargo on follow on flights. That will reveal how operators are exploiting the flexible volume.

- The length and content of HTV-X1’s free flight demo phase. Payloads like deployable antennas and advanced solar cells will indicate where near term commercial interest is strongest.

- A docking demonstration campaign. When hardware that matches the International Docking System Standard flies and proves out, the Gateway readiness story becomes concrete.

The bottom line

HTV-X1 is a logistics upgrade you can measure in hours saved before liftoff, watts delivered to cargo en route, and months of extra value after unberthing. It gives the International Space Station a smarter supply line now and seeds the exact technologies a lunar resupply ship must carry later. The result is a single architecture that works inward for today’s needs and outward for tomorrow’s ambitions. Japan did not just send up a cargo ship in late October. It launched a supply chain that already stretches from a clean room near the loading dock to an outpost in lunar orbit. That is how a freight network begins.