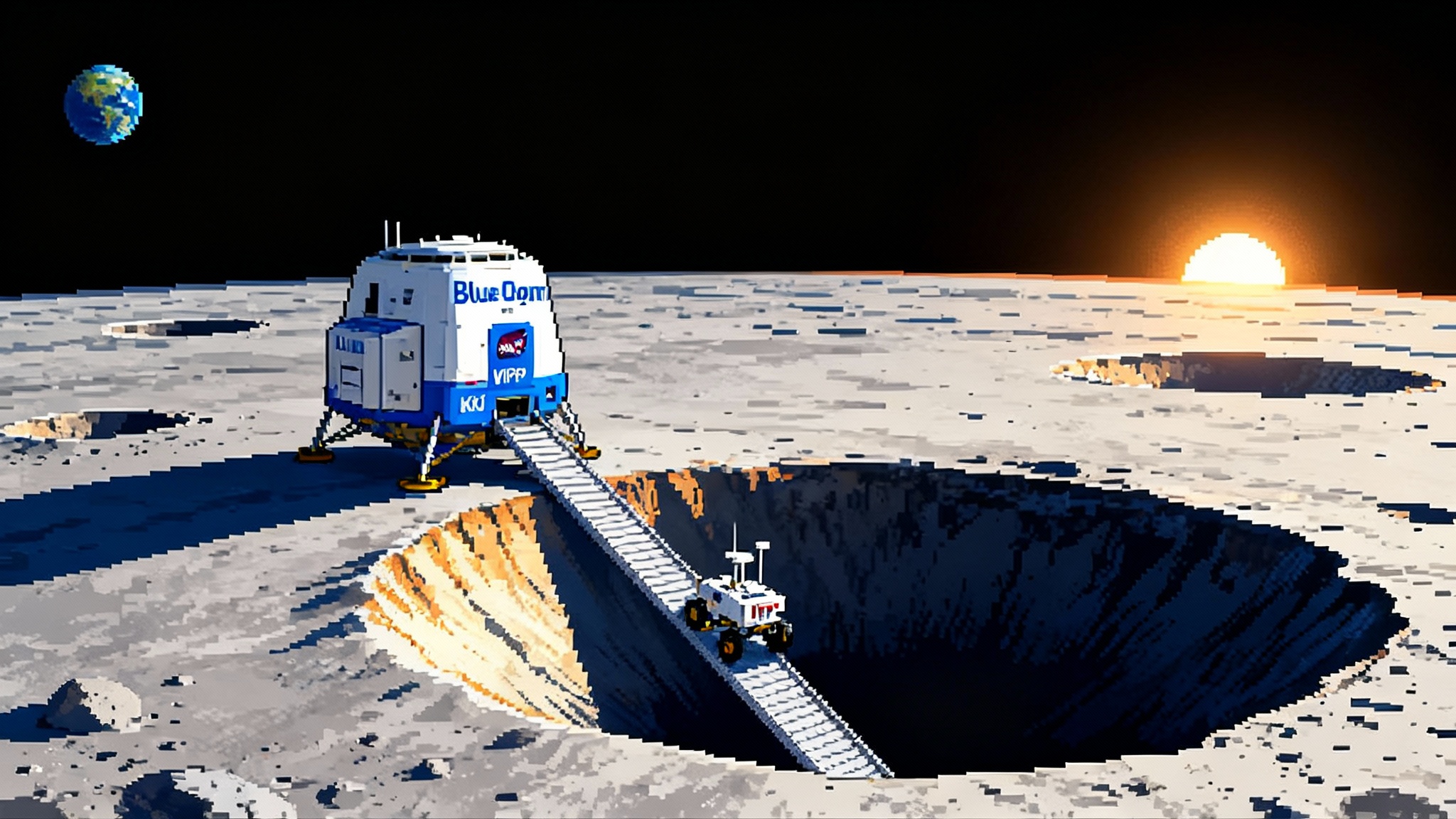

VIPER is back: Blue Origin set for 2027 south pole delivery

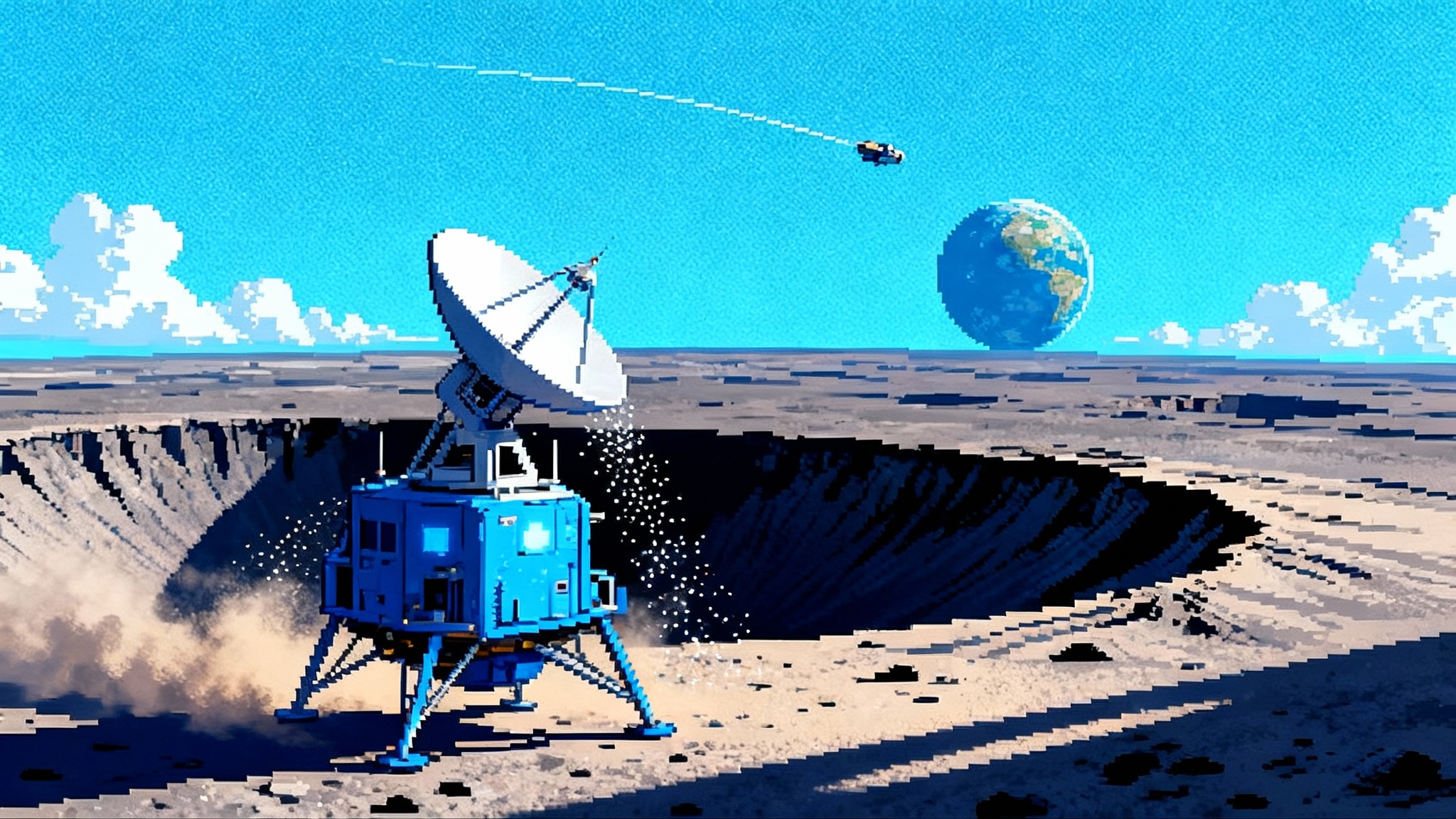

NASA restored the VIPER rover in September 2025 with a conditional ride on Blue Origin’s Blue Moon MK1. If the demo lander touches down by late 2025, VIPER heads for a late 2027 south pole delivery to drill for accessible lunar water ice.

A surprise revival with a clear gate

NASA closed out September 2025 by reviving a mission many had already eulogized. The Volatiles Investigating Polar Exploration Rover, better known as VIPER, is back on the manifest under a conditional task order within the agency’s Commercial Lunar Payload Services program. The deal is simple and strict. Blue Origin must first complete a demonstration landing of its Blue Moon MK1 cargo lander by late 2025. If that touchdown succeeds, the green light turns on for a late 2027 VIPER delivery to the Moon’s south pole.

That structure is more than a contract term. It is a design philosophy for the Artemis era. A milestone gate focuses attention on the few events that truly matter, allows NASA to manage risk without freezing innovation, and gives industry a chance to turn capability into cadence. The CLPS model that let Blue Ghost made the Moon commercial is the same framework now steering VIPER back toward the surface.

Why the south pole matters now

There is water on the Moon, but not in the way we find it on Earth. At the lunar south pole, sunlight skims the terrain at a shallow angle. Mountains and crater rims bask in near constant light while deep craters never see the Sun at all. Inside these permanently shadowed regions, temperatures plunge far below minus 200 degrees Celsius. Molecules of water that migrate across the surface can become trapped there as ice, potentially for billions of years. Recent results suggest that farside rocks rewrite the Moon’s water map, sharpening the case for targeted prospecting.

For exploration, that ice is not just a scientific curiosity. It could be feedstock for a supply chain. Split water into hydrogen and oxygen and you have propellant. Liquefy oxygen for life support and store hydrogen for fuel cells and rocket stages. The trick is turning ghost-cold frost and buried deposits into reliable, daily inventory. That requires information at a level of detail you can only get by going there with the right tools, sampling at depth, and mapping not just where ice is, but how it is mixed into the regolith and how hard it is to extract.

VIPER’s tool kit and what it can actually tell us

VIPER was built for this exact job. It carries a one meter drill known as TRIDENT, short for The Regolith and Ice Drill for Exploring New Terrain. TRIDENT is designed to bite through crusty, cemented soils and powder-fine dust alike, pull up cores from successive depths, and deliver those samples to a suite of spectrometers.

Three instruments work together to turn those cores and the surrounding terrain into a three-dimensional map of volatiles:

- A neutron spectrometer system senses hydrogen in the ground beneath the rover, offering a fast, wide-area indicator of potential ice before drilling. Think of it as a metal detector for water.

- A near infrared spectrometer peers at disturbed soil and core samples to identify frosts and hydrated minerals and to estimate the grain size and cleanliness of any ice it sees. The distinction matters, because clean, coarse ice is far easier to harvest than ice locked inside fine grains or mixed with salts.

- A mass spectrometer analyzes gases released as samples warm, measuring how much water and other volatiles are actually present. It is the ground truth step that converts hints into numbers.

Together, these instruments can answer four questions that matter for in situ resource utilization, often shortened to ISRU. First, how deep do you need to dig before you hit meaningful concentrations. Second, how patchy are those deposits across a rover-scale traverse. Third, how tightly is the ice bound in the soil, which affects energy per kilogram to extract. Fourth, how much non-water volatile contamination you should expect in the process stream.

VIPER is not a refinery and it is not a pilot plant. It is a geologist, prospector, and scout rolled into one. Its product is data, the kind of data engineers can use to design miners, hoppers, heaters, and condensers that have a fighting chance of working in polar night.

The conditional path from 2025 to 2027

The timeline set out with the September 2025 decision is blunt. Blue Origin must complete a Blue Moon MK1 demo landing by late 2025 to convert the paper plan into a delivery schedule. If the demo succeeds, the VIPER task order under Commercial Lunar Payload Services transitions from conditional to active. From there, the team has roughly two years to integrate, test, and deliver. That pacing is aggressive but grounded in what matters most.

- 2025 demo as the reliability gate: Blue Moon MK1 must demonstrate the key risk reducers for a heavy cargo delivery. That includes precision landing, engine throttling and plume control near the surface, autonomous hazard avoidance in rugged polar terrain, and a payload deployment sequence that puts a rover on the ground without drama.

- 2026 integration as the compatibility gate: VIPER’s mobility system, avionics, power, and thermal design must be synchronized with the lander’s mechanical interfaces, ramp geometry, and environmental controls. Thermal management will be a particular focus; the rover must survive local cold traps and shadowed traverses while the lander’s proximity and shadowing do not over-cool or over-warm key components.

- 2027 delivery as the operational gate: Surface operations at the south pole are constrained by illumination windows, communications geometry with Earth or with orbiting relays, and the safe traverse corridors between sunlit ridges and shadowed science targets. The delivery must hit a window that allows commissioning, scouting, and drilling in the same season of light.

This gated model is a quiet revolution. Instead of dictating detailed design choices up front, NASA is paying for capability proven in flight. If Blue Moon MK1 does not complete the demo, the mission does not advance. If it does, the incentive is to turn a working lander into a repeatable service. That is the Commercial Lunar Payload Services idea at its most focused.

What success looks like on the surface

Imagine the first week of operations in late 2027. VIPER rolls down a ramp onto crunchy regolith, its wheels engineered to keep traction in loose dust and to climb slopes without digging in. The neutron spectrometer starts sniffing for hydrogen-rich patches. When the count rises, the rover stops and uses TRIDENT to take a shallow core. As the core warms inside a small oven, the mass spectrometer notes a spike in water vapor and a whisper of other gases. The near infrared spectrometer finds water ice grains larger than a few hundred microns mixed with fines.

That single sequence would already be a turning point. A clean signal near the surface means less excavation and lower energy per kilogram. A noisy, volatile-laced signal at depth would mean more heating and more filtration. A patchwork of small, rich pockets might favor a mobile miner with short hops and a staging hopper, while broad, moderate deposits might favor a stationary harvester with a longer residence time. Either way, the engineering conversation changes from guesses to trade studies.

Over two or three months, VIPER could stitch together a practical map. Not just a pretty picture, but something like a field manual: where to dig, how deep, how much energy to budget, how to handle contaminants, where to stage power and communications, and which routes are safe for wheeled or legged haulers. That manual would ripple outward into Artemis planning, informing where to place power stations, where to cache cryogenic storage, and how to schedule crewed excursions around robot activity.

From prospecting to propellant: the missing middle

There is a seductive idea that water ice equals rocket fuel on tap. The truth sits in a demanding middle layer where prospecting meets processing. Converting ice-bearing regolith into useful mass requires solutions to five linked problems.

- Excavation and conveyance. Polar regolith can behave like talcum powder in one layer and like cemented gravel in the next. Hardware must resist abrasive wear, tolerate pebble-sized clasts, and keep moving at minus 150 degrees Celsius. Designs that use enclosed augers, gentle vibratory feeders, and dust-tolerant bearings stand a better chance.

- Thermal extraction. Getting water out of dirt takes heat. If the ice is clean and near the surface, solar thermal concentrators might do the job. If it is deeper and mixed with fines or salts, resistive heating or microwave dielectrics could be more efficient. VIPER’s measurements of depth and mixing are the difference between megawatts and kilowatts in the energy budget.

- Gas handling and purification. Water released from cold regolith carries other volatiles along for the ride. A workable plant needs cold traps and zeolite beds sized for the actual mix. Again, the mass spectrometer’s profiles tell you whether to pack more filters or more heaters.

- Electrolysis and liquefaction. Splitting water into hydrogen and oxygen is well understood, but doing it in a dusty environment at lunar gravity introduces new failure modes. Cooling the gases into cryogenic liquids requires long-duration sinks and smart sun-shielding. Ice maps that keep processing plants in the light and delivery routes short reduce boil-off losses.

- Storage and distribution. Liquid hydrogen wants to escape. Super-insulation, vapor-cooled shields, and boil-off re-liquefaction cycles all compete for mass and power. A south pole supply chain will likely combine local liquefaction near high ground with frequent small transfers, not rare huge ones, to keep losses manageable.

VIPER cannot solve these problems by itself, but it can trim the uncertainty that makes early systems heavy, power-hungry, and unreliable. A ten percent improvement in certainty about ice depth and cleanliness can remove tons of thermal hardware and hours of night-time churn out of a pilot plant design.

Why a milestone-gated commercial model matters

A conditional task order does something politically and practically valuable. It turns risk into a sequence of public, verifiable events. Did the lander fly when promised. Did it land where planned. Did the payload deploy and work. Each step earns the next.

For NASA, this creates a way to buy outcomes instead of prescribing every bolt. It reduces overhead while keeping a tight grip on mission-critical milestones. For companies, it aligns survival with execution. Succeed on the demo and you open the door to revenue that supports a real product line. Fail and the system encourages competitors to take the next shot.

The pacing also forces discipline in interfaces. To hit a 2027 delivery, VIPER has to mate to standard payload mounts, accept standard power and data connections, and respect standard mass and volume envelopes. These are not just paperwork wins. They are the standards that let future rovers, drills, and processors ride whichever lander can make the next window. That cross-compatibility is how cadence forms.

Finally, the gate ties mission risk to private capital where it makes sense. A company will only put its own money behind a demo it believes it can execute. When it does, the upside is a service that can fly again and again, turning the Moon from destination to workplace.

The moment to watch

Between now and the end of 2025, the key moment is that Blue Moon MK1 descent. A clean landing will not guarantee an easy road to 2027, but it will finally align three forces that rarely arrive together in spaceflight: a paying customer with a clear need, a vehicle designed to deliver heavy cargo to the right address, and a payload built to answer the questions that unlock a market.

If those forces line up, the south pole will stop being a place on a map and start being a place with schedules. VIPER will be the first foreman on shift. And if it does its job, the next vehicles to roll down a ramp will not just be explorers. They will be the first machines in a lunar economy.