Project Pele’s Truckable Microreactor Reaches Reality

2025 marks the turn from drawings to metal for Project Pele. A truck-movable, containerized microreactor delivering 1 to 5 megawatts could free Indo-Pacific outposts from risky fuel convoys and power radar, laser defense, and autonomous systems. Here is the roadmap, rules, and risks.

The year the boxes arrive

For years, military microreactors were a promise on slides. In 2025, the U.S. Department of Defense moved shovels and steel. The Strategic Capabilities Office broke ground at Idaho National Laboratory and set assembly in motion, describing a reactor that travels in four standard 20‑foot containers and delivers one to five megawatts of electric power. “We are thrilled to move beyond the era of PowerPoint advanced reactors,” said Project Pele manager Jeff Waksman when the plan was announced. The signal was clear. This is no longer a study. It is hardware on a clock. DoD’s ground‑breaking release captured the pivot.

That pivot matters most in the Indo‑Pacific, where distance makes energy a vulnerability. Every gallon of diesel dragged by barge or convoy to an island base is a target, a schedule constraint, and a drain on combat power. A truck‑movable reactor that runs for years without refueling changes the math.

Why the Indo‑Pacific needs portable nuclear now

Think of energy at a forward outpost as the oxygen for operations. When the oxygen arrives by ship and tanker, adversaries do not need to suffocate you directly. They can just squeeze the supply line. In a theater defined by narrow straits and long sea lanes, fuel convoys are predictable and exposed. Weather delays, port capacity, and contested logistics make every refuel a roll of the dice.

A microreactor on site turns supply stairs into an elevator. Instead of repeating shipments of liquid fuel, commanders bring in a sealed energy core that runs for several years, then ship it out for defueling and inspection. The difference is not subtle. Remove recurring bulk fuel deliveries and a base can operate through air and maritime interdictions that would otherwise turn off radars, reduce sortie generation, ground counter‑UAS lasers, and starve autonomous systems of charge.

What one to five megawatts unlocks

One to five megawatts of continuous electrical power falls short of a city but is transformational for a remote outpost. Here is what that level buys in practical terms:

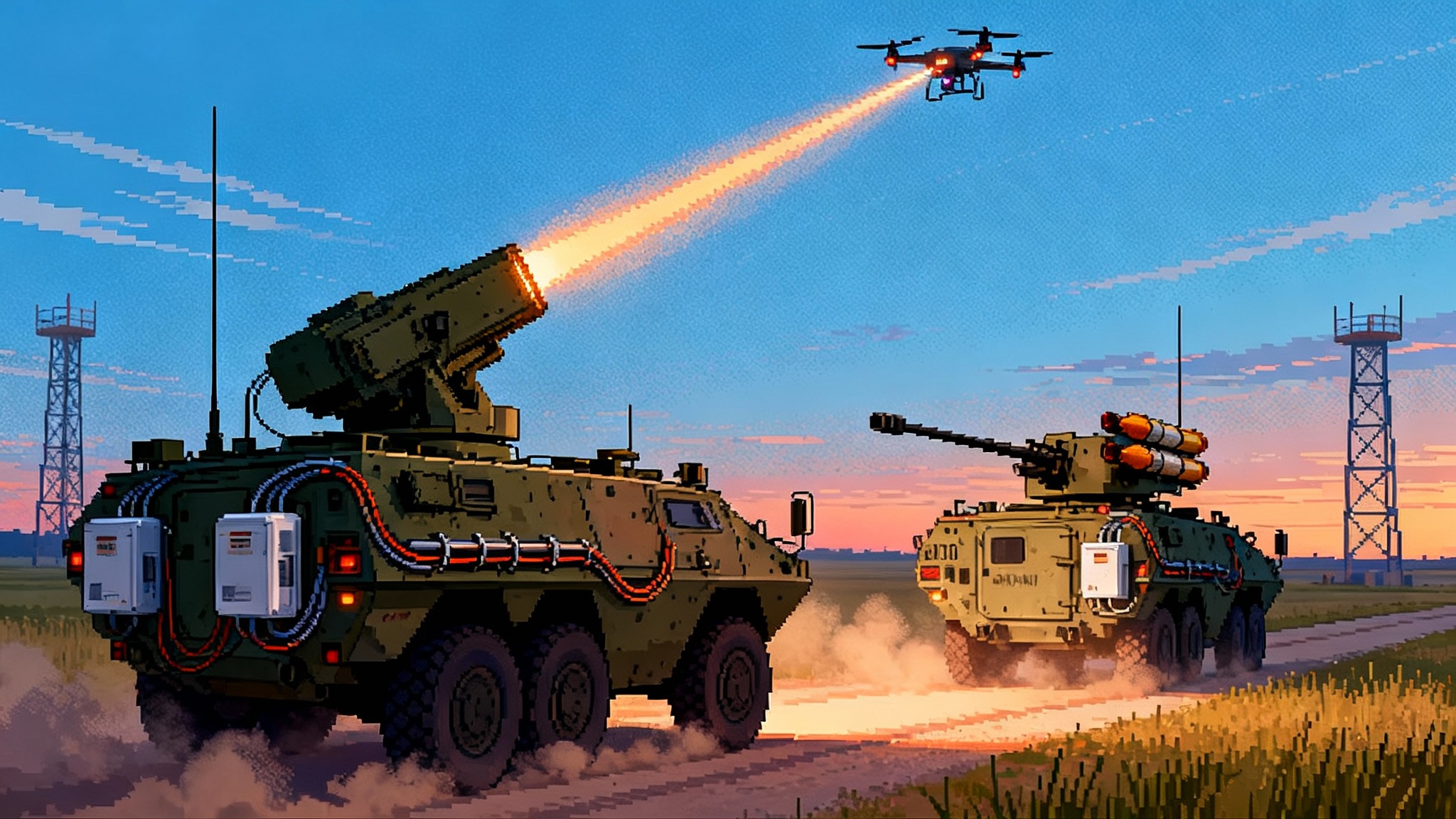

- High‑energy radar. A modern long‑range active electronically scanned array can draw power in the low megawatts when sweeping at full duty cycle. With a dedicated microreactor, a base can operate radar at sustained peak modes instead of pulsing schedules around fuel shipments. The operational result is longer detection ranges and better tracking in bad weather.

- Laser air defense. A continuous wave laser in the 150 to 300 kilowatt class requires roughly one to three megawatts at the plug once you include power conditioning, thermal management, and control systems. A microreactor can run that load steadily for hours, which means repeated engagements against swarms without waiting for diesel generators to cool or for battery storage to recharge. For recent field context, see Army laser air defense goes live.

- Autonomous systems charging. A detachment of small uncrewed aircraft launching persistent patrols can require tens of megawatt‑hours per day when you add up rapid charging, data processing, and communications. Microreactor power turns charging from a scheduling bottleneck into a background service. This aligns with the surge described in Replicator mass in the Pacific. Add a containerized high‑temperature water desalination skid and the same plant can make mission water as a byproduct of waste heat.

- Edge compute and networking. Sensor fusion and targeting pipelines benefit from on‑site data processing. Artificial intelligence models running on graphics and tensor processors need consistent power and dense cooling. A microreactor supports that compute without throttling to match generator cycles.

These capabilities compound. If you can run high‑duty radars and laser defense while charging drones and crunching sensor data, the outpost moves from a footprint you must hide to a node you can fight from.

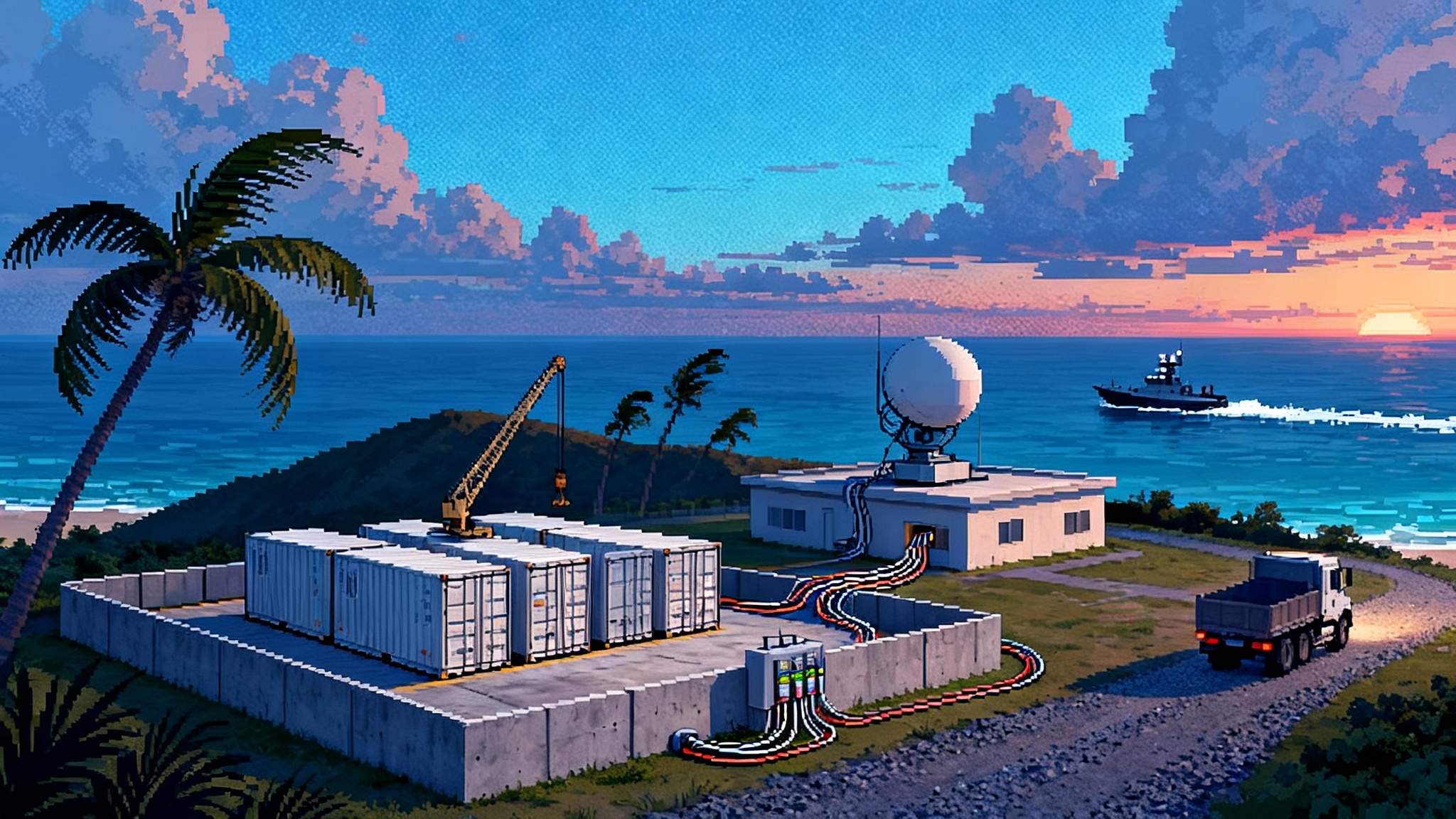

The hardware inside four boxes

Project Pele’s prototype is a high‑temperature gas‑cooled microreactor. The fuel is tristructural isotropic, which engineers shorten to TRISO. Each TRISO particle is a ceramic armored kernel of uranium wrapped in layers of carbon and silicon carbide. The particles are embedded in graphite. Think of millions of tiny pressure vessels, each with its own containment. TRISO behaves very differently from the long metal rods familiar from commercial reactors. It tolerates high temperatures, it is hard to damage mechanically, and it resists meltdown because there is no long metal cladding to fail and no large shared coolant loop to boil off.

The working fluid is inert gas, not water, so pressure and heat management are simpler under accident scenarios. Heat moves from the reactor core to a power conversion unit that turns it into electricity, then to heat exchangers for rejection. The system is built to be assembled and disassembled with standard heavy equipment. Nothing about the plant requires custom oversize transport. That is the point. If it does not fit on a flatbed, it does not belong in the Pele design.

TRISO fuel also supports the mission profile. Instead of routine refueling, a Pele unit operates for several years on its initial load of high assay low enriched uranium, then is shut down and shipped back inside its shielding for refueling under controlled conditions. This is how you make nuclear compatible with maneuver.

How it actually moves

Fieldability is a chain of practical steps, not a slogan. Here is what commanders should expect once the prototype completes testing:

- Movement to theater. The sealed reactor module and balance‑of‑plant containers move by truck and standard cargo aircraft or roll‑on roll‑off ship. Prepositioning at a logistics hub is sensible so the reactor never has to sail through contested chokepoints while fueled.

- Site setup. The receiving site needs a prepared pad, a modular concrete or earthen shield structure, and a microgrid tie that includes power conditioning and breakers. Shield blocks are designed to be stacked quickly with a crane. The design anticipates days to initial operation rather than long weeks.

- Start and tie‑in. After on‑site checks and safety reviews, the reactor goes critical and ramps to the planned output. Power flows either to tactical loads through a microgrid or to resistive load banks during test and evaluation.

- Pack‑out. When the mission ends or the core life expires, the plant is shut down, cooled, and disassembled into its original containers. The reactor module is shipped to a licensed facility for defueling and inspection.

Each step relies on equipment and skills units already train for. That is why containerization matters. It turns nuclear power into logistics, not civil works.

The 2025 to 2028 test milestones that matter

Project Pele has crossed paperwork and is now in metals and fuel. Here is the near‑term map, with dates that commanders and program watchers can track:

- Assembly begins. The Department of Defense has stated that assembly of the final reactor is set to begin in February 2025. That is the first inflection where supply chains, welds, and quality assurance replace renderings.

- Core manufacturing underway. BWX Technologies announced on July 24, 2025 that it started fabricating the reactor core at its Lynchburg campus, and described Pele as a 1.5 megawatt demonstration expected to produce electricity by 2028. The company’s update is the clearest indicator of manufacturing pace and schedule maturity. See BWXT’s note on start of core manufacturing.

- INL site buildout in 2025 and 2026. Idaho National Laboratory is preparing the test location and shield structure, with plans to receive the assembled reactor during the 2026 window. Connection to INL’s microgrid allows realistic load following and fault testing.

- Fuel and first power. The target for initial power shifted from early optimistic goals toward late‑decade realism as high assay low enriched uranium supply and first‑of‑a‑kind manufacturing steps cleared. BWXT’s 2025 update pointing to 2028 power is credible because it ties the promise to the fuel line and the core in production.

Two observations add needed nuance. First, DOD’s early schedule placed transport and initial testing in 2026, which remains important since it yields real integration data even if first sustained power comes later. Second, the U.S. fuel ecosystem is catching up. New equipment coming online to produce advanced TRISO and high assay low enriched uranium narrows the schedule risk that dominated earlier years. Commanders should plan for meaningful field data in 2026 and realistic power demonstration by 2028.

The regulatory path from prototype to field unit

The prototype demonstration at Idaho National Laboratory operates under the Department of Energy’s safety oversight, not under the Nuclear Regulatory Commission. That is backed by an Environmental Impact Statement and a Record of Decision issued in 2022 that specifically evaluated construction and demonstration at the Idaho site. For the prototype, the nuclear safety authority rests with the Department of Energy’s Idaho Operations Office.

What happens after the prototype matters more to a commander:

- Domestic fielding outside Department of Energy sites. The Nuclear Regulatory Commission has stated it can license microreactors today under existing frameworks, specifically 10 Code of Federal Regulations Part 50 or Part 52, and is developing a technology‑inclusive advanced reactor rule known as Part 53. A DoD base seeking a persistent, non‑experimental unit would need a regulator and a licensing basis. That can be through Nuclear Regulatory Commission licensing, or through a Department of Energy construct if the plant remains a Department of Energy asset on a base. Each path changes siting, security, and operator training.

- Overseas deployment. Any forward deployment outside the United States triggers host nation agreements, status of forces arrangements, and local nuclear regulatory engagement. Commanders should expect longer timelines and early diplomatic work to define emergency planning zones, liability, and waste logistics.

- Waste and pack‑out. Pele is designed for full pack‑out of the reactor module and fuel. That reduces long‑term site stewardship and simplifies agreements, but it requires certified routes and receiving facilities. Unit logisticians should design routes in peacetime and exercise them.

Commanders do not need to become licensing experts, but they should assign a lead to track three milestones: the prototype’s safety reviews at Idaho National Laboratory, the first operator training certifications, and the chosen pathway for fielded units. Those three gates will govern when a unit can receive power from a truckable reactor in the real world.

The targeting and cyber risks you must mitigate

Nuclear does not erase risk. It changes it. The microreactor removes recurring fuel convoys but adds a high‑value node. Here are the specific threats and practical countermeasures:

- Precision fires and drones. A reactor pad is a fixed point that adversaries can map. Mitigate by siting under terrain masking, using hardened and modular shielding that doubles as fragmentation protection, and creating decoy heat and electromagnetic signatures with generator farms and heated containers. Lay out the microgrid with redundant feeders so power flows even if one segment is cut. Pair this with high power counter UAS options to thin incoming swarms.

- Long‑range surveillance. Satellites and radio‑frequency mapping can detect distinctive thermal and electrical signatures. Use signature management from day one. Bury or berm cabling, route exhaust plumes through ground‑level dispersers, and avoid straight runs of radiating bus.

- Insider and close‑in threats. Nuclear safety relies on procedure. Keep the operator team small and cross‑vetted. Embed a red‑team function to test access control, badge logic, and shift‑change discipline before deployment.

- Cyber intrusions. Treat the plant’s industrial control system as a separate organism. Segment it from enterprise networks. Use hardware data diodes for any one‑way monitoring paths. Disable unused services and ports. Maintain a frozen, hashed software baseline and verify it before each start. Run an independent monitoring stack that looks for anomalous control traffic and sensor spoofs.

- Electromagnetic pulse and power quality. The loads Pele will feed are sensitive and the plant will sit under potential high altitude electromagnetic pulse conditions. Harden key components, add surge protection, and pre‑stage spare inverters and breakers. Exercise black‑start with the actual radar or laser the plant will power, not just with resistive load banks.

- Radiological contingencies. Even meltdown‑resistant fuel needs a playbook. Train immediate actions for fire, fragment strikes, and flooding. Stock modular shielding blocks and remote handling tools on site. Practice a cold‑shutdown drill with a live clock and a third‑party observer.

None of these measures are exotic. They are the same discipline the services already apply to ammunition depots and satellite ground stations, adjusted for nuclear.

A commander’s checklist for 2025

The program is crossing from concept to kit. Here is a concrete to‑do list for units and installations that expect to use Pele:

- Pick sites now. Select two or three candidate pads on each installation, including one with terrain masking. Pre‑run utilities and fiber to the perimeter, not the center.

- Build the microgrid. Install a ring bus with sectionalizing switches and standardized connectors where the containers will land. Integrate battery storage sized for at least ten minutes of full load to ride through faults and switchovers.

- Preposition shielding. Contract modular concrete or earthen block vendors and stage enough to build a secondary shield wall and a protected operations shelter. Do it before the first reactor arrives.

- Train the operators. Identify the small team that will own the plant. Pair them with Idaho National Laboratory during prototype testing. Require cross‑training on both nuclear operations and microgrid protection.

- Write the pack‑out plan. Coordinate certified routes and receiving facilities for the reactor module. Include customs and host nation approvals for overseas missions. Run a tabletop exercise with the actual players who will sign the paperwork.

- Exercise the loads. Prove that your radar, laser, and autonomous system chargers behave well under Pele’s power, including sudden step changes and protection trips. Fix harmonics and grounding issues now, not during a crisis.

- Decide the regulatory path. Work with service headquarters to determine whether your first fielded unit will be a Department of Energy asset on a base or a unit licensed through the Nuclear Regulatory Commission. This choice drives timelines and training.

The bottom line

Project Pele’s value is measured in fewer tankers, steadier sensors, and mission systems that do not blink when the sea lane closes. In 2025 the program crossed its inflection point. Government statements and company manufacturing updates show the prototype is leaving the world of concept art and entering weld shops and fuel lines. The Department of Defense expects assembly milestones and Idaho site work through 2025 and 2026, and BWX Technologies has tied initial electricity production to the 2028 window as core fabrication and fuel manufacturing mature.

Commanders should act now. Build the microgrids. Train the operators. Preposition the shielding and write the pack‑out plan. The first microreactor you receive will not eliminate your risk. It will give you a different kind of risk with more control and fewer convoys. In a theater where distance is the adversary’s best friend, that trade is worth making.