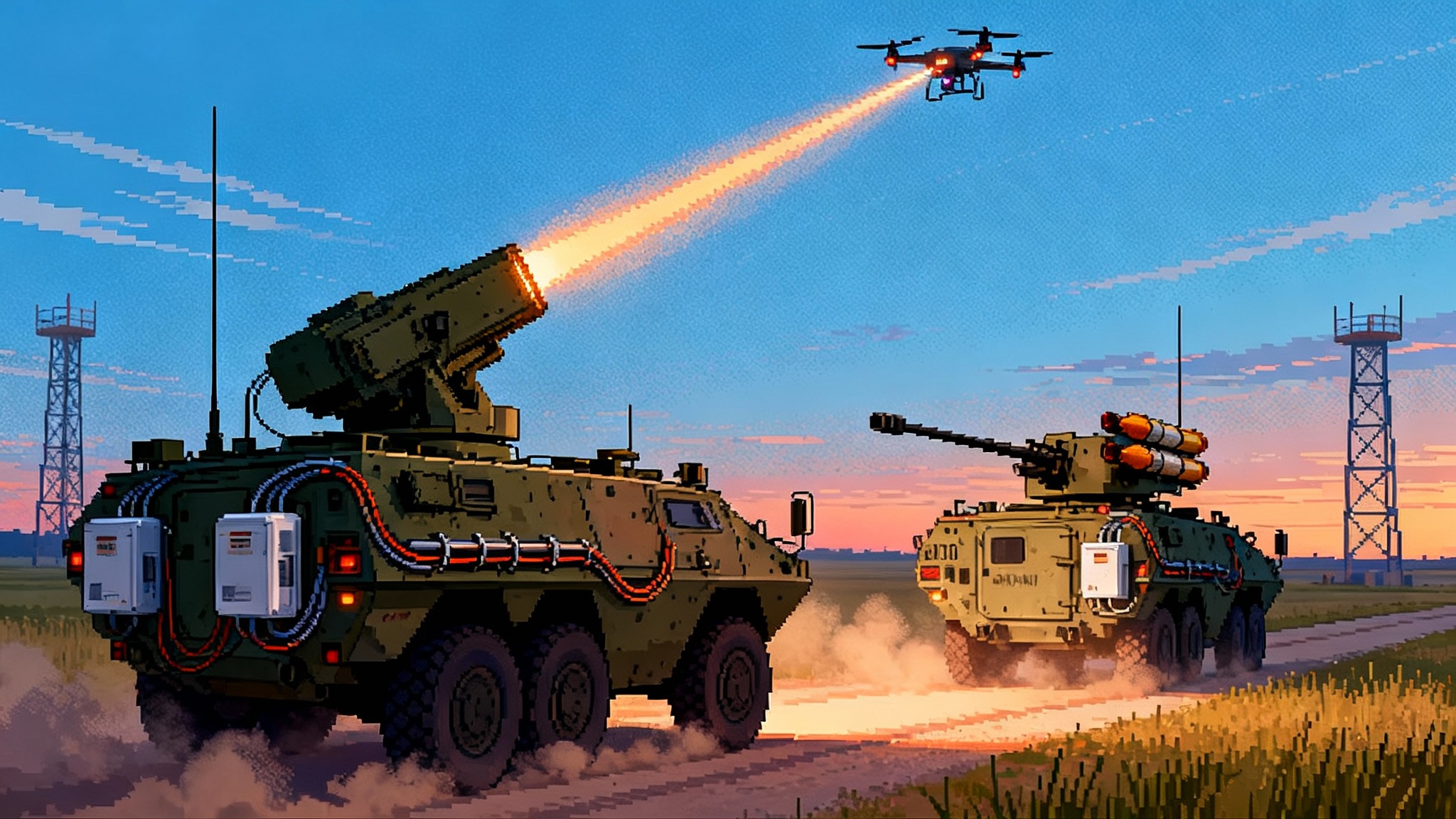

Army Lasers Go Live: Strykers Flip the Drone Math

At Fort Sill this summer, the Army's 50 kilowatt laser Stryker moved from showpiece to playbook. Here is how pairing directed energy with kinetic M-SHORAD can upend counter-drone costs and why brigade level coverage by 2027 is within reach.

The summer the laser got real

Fort Sill, Oklahoma, is where new air defense ideas earn their place in doctrine. This summer, soldiers there ran live fire events that put the Army’s Directed Energy Maneuver Short Range Air Defense, or DE M‑SHORAD, shoulder to shoulder with the kinetic M‑SHORAD Stryker that carries Stinger missiles and a 30 millimeter cannon. In June 2025, the Army reported a series of live fires that integrated prototype laser systems against swarming small drones, the very threat that has overwhelmed many traditional defenses in recent conflicts. The tests were not just another demonstration. They were dress rehearsals for field tactics, training and sustainment, with operators refining how lasers, missiles and guns trade shots in the same fight. Fort Sill live fire, June 2025.

If the acronym list is new, here is the quick translation. M‑SHORAD is Maneuver Short Range Air Defense, a Stryker mounted system that protects brigade combat teams on the move. DE means directed energy. HEL stands for high energy laser. Put them together and you get DE M‑SHORAD, a 50 kilowatt class laser mounted on a Stryker, built to blind, burn and break small unmanned aircraft systems that are cheap, plentiful and hard to track with radar alone.

The prototype lineage matters. The Army’s Rapid Capabilities and Critical Technologies Office, often called RCCTO, led the charge on early DE M‑SHORAD vehicles. Kord Technologies has been a key integrator for the Stryker package; RTX, formerly Raytheon, built the 50 kilowatt laser and beam director. General Dynamics Land Systems provides the Stryker chassis. The goal has never been lasers replacing missiles. The goal is a layered team where lasers swat the cheap stuff, the cannon cleans up what slips through, and missiles are reserved for high value threats.

To see how this fits the broader kill web, compare it with the Army’s any sensor, best weapon approach in IBCS 2025 breakout moment.

The economics that flip the drone fight

A small drone that costs a few thousand dollars imposes a cruel trade if you spend a missile worth hundreds of thousands of dollars to stop it. That is the asymmetry adversaries have exploited. Lasers change the trade. Each shot is essentially electrical energy converted to heat on target. The cost is fuel burned to generate power, plus maintenance and crew time. On a Stryker, that often means dollars per engagement rather than six figures. Cost per shot collapses.

Magazine depth changes too. A missile rack runs out after a handful of shots. A laser’s magazine is power and cooling. If the power system keeps charging and the thermal loop stays in its safe window, the crew keeps firing. Think of kinetic interceptors like bottled water; every bottle you use is gone. A laser is more like a purifier hooked to a stream; as long as you keep the pump running and the filter cool, you can pour glass after glass. Sustained fire is a logistics function, not a munition count.

This flip matters most when the problem is volume. Groups of small drones fly low, cross in and out of clutter, and try to saturate a battery’s engagement timeline. With a 50 kilowatt beam and good tracking, a crew can hold a spot on a drone’s motor or control surfaces for a second or two and wreak enough thermal damage to crash it. It is quiet, fast, and repeatable as long as the vehicle stays powered and cooled.

What changed under the hood: power and thermal

Moving from demonstration to doctrine required more than a stronger laser. It took engineering on power generation, energy storage and heat rejection, the invisible backbone of an operational laser weapon.

-

Hybrid power. The Stryker configuration uses a combination of battery energy storage and a diesel generator. Batteries handle transient spikes when the laser ramps up. The generator keeps the pack topped off and supports repeated engagements. Hybridization avoids the slow throttle response of a diesel alone and protects sensitive electronics from voltage sag.

-

Smarter power conversion. High energy lasers are picky about clean power. Modern power electronics condition voltage and current so the beam stays stable when the platform is bouncing, turret motors are slewing, and radios are transmitting. Software monitors load, predicts peaks, and sequences subsystems so the laser always gets priority during a shot.

-

Denser thermal plumbing. Every watt of laser light sent downrange starts as electrical power and leaves waste heat behind. The near term breakthrough is not an exotic coolant; it is packaging and control. Crews now have liquid cooling loops tied to compact chillers and thermal storage. The system can absorb heat through a burst of engagements, then dump that heat efficiently while the vehicle repositions. Better pumps, better valves, and better control algorithms keep temperatures inside the safe band and reduce the number of cool down pauses that used to kill tempo.

-

Ruggedized optics and beam control. The beam director has to hold aim on a dime while the vehicle vibrates. Improvements in gimbal stabilization, optical coatings, jitter control and target tracking have made the 50 kilowatt class practical on a moving Stryker instead of a sheltered test pad. That is why live fire at Fort Sill focused on operator drills like handoff from radar track to electro optical lock, and then to laser dwell.

None of this is sci fi. It is truck level engineering done with hard rules about size, weight and power. The new pieces are better integration and control so the crew can fight, not babysit a science project.

From prototypes to an enduring program

The Army is pushing to move lasers from urgent prototypes into an enduring, competed program that can buy at scale. The effort is called Enduring High Energy Laser, often shortened to E‑HEL. Senior leaders have described a 2026 competition window to drive industry toward systems that can be produced, sustained, and repaired by soldiers in the field, not engineers in a lab. Army readies 2026 laser competition.

Why the emphasis on enduring. Prototypes are fast and flexible, but they are hard to sustain across multiple battalions. An enduring program sets standards for interchangeable laser modules, common power and thermal components, and software that can be updated across a fleet. It also creates a logistics spine for spare pumps, seals and chillers, and a training pipeline that turns air defenders into laser maintainers. The industrial momentum mirrors what we have seen as other programs scale, from space shield takes shape to NGJ Mid Band enters service.

Industry has been signaling readiness. Companies like RTX have invested in spectrally combined fiber lasers that scale toward higher power in compact packages. Kord and General Dynamics have iterated the Stryker integration to protect sight lines, reduce vibration, and simplify access to line replaceable units. New industrial facilities announced in 2025 focused on high energy laser integration show that vendors expect a program of record to buy more than a handful of vehicles. The message is clear. The Army will not accept one off marvels. It wants a stable recipe it can cook by the dozens.

How lasers and kinetic M‑SHORAD actually fight together

Picture a brigade combat team moving to contact. Overhead, a small drone appears that is only a few pounds, with a commercial camera and a simple warhead. That is a laser shot. The crew slews, the beam locks, and a short dwell on the propeller hub sends the drone tumbling.

Minutes later, a larger uncrewed aircraft trundles in hauling a heavier payload. The crew weighs the target. If the drone is within laser reach and conditions are clear, the laser still goes first. If it is faster or masked by haze, the 30 millimeter cannon with airburst is next. Keep missiles reserved for the helicopter or fixed wing aircraft that might be stalking the formation. The point is not to pick favorites. The point is to pick the cheapest tool that works for the threat you see. This is the same logic behind the Army’s any sensor, best weapon model described in IBCS 2025 breakout moment.

This layered approach protects the ammunition supply chain. It also frees commanders to keep pace. The Stryker can fire the laser in near silence. That is valuable for surprise and for avoiding blue on blue after action confusion when multiple batteries engage the same small drone with different weapons at once.

A realistic path to brigade level coverage by 2027

No plan survives first contact. Still, the past year points to a plausible path that puts lasers in real numbers across Army formations by 2027.

-

Summer 2025, Fort Sill live fires. Soldiers refine tactics, techniques, and procedures for handoff, deconfliction and engagement timelines. Maintenance teams track mean time between failures on pumps and power electronics during extended events, not just short demos.

-

Fiscal year 2026, enduring competition opens. The Army writes requirements that stress reliability, maintainability and production at scale. Vendors submit systems with modular power and thermal designs, common spares, and software that can be updated on a unit schedule. The government downselects and releases long lead buys for shared components like chillers.

-

Calendar year 2026, low rate production ramps. Initial vehicles go to training bases and one operational unit per theater for final soldier touch. Mobile repair kits and depot tooling get bought in parallel, avoiding the trap of fielding hardware before the sustainment pipeline exists.

-

2027, brigade level coverage arrives. A typical division aligned air defense battalion could carry a mix of kinetic M‑SHORAD and DE M‑SHORAD, with at least one laser platoon per brigade combat team. That mix gives commanders the freedom to assign lasers to drone heavy sectors while keeping missiles for high end threats. If industry hits reliability goals, nothing in this schedule requires a moonshot technology leap. It is a logistics and training sprint.

Two things keep this on track. First, the Army must resist design creep. Lock the baseline at 50 kilowatts on Stryker for near term fielding, then spiral upgrades later. Second, the Army must buy spares like it means to fight. Pumps, seals, coolant, and power control boards are the real magazine for a laser unit.

What still needs work

-

Weather and obscurants. Fog, rain, dust and smoke all degrade laser performance. The answer is doctrine, not hand waving. Use lasers first when the air is clear. Shift to cannon and missiles as atmospheric penalties rise. Make this a checklist item during mission analysis.

-

Aimpoint and aim time. Lasers need a precise aimpoint and a short dwell. That demands better target recognition and tracker handoff inside the fire control software. Training should drill crews on selecting structural aimpoints like motor hubs and control linkages.

-

Vibration and alignment. Strykers bounce. Crews need routine boresight checks and simple alignment tools they can run in the motor pool. Line replaceable units must swap without days of recalibration.

-

Power electronics life. High switching frequencies and heat shorten component life. Contract language should require vendors to expose health data through built in test so units can replace parts before failure, not after.

-

Safety and rules of engagement. Laser safety in a 360 degree fight is not a footnote. Units need clear rules for beam control near friendly air corridors, and simple procedures for eye safe training that still builds combat muscle memory.

How to accelerate without breaking things

-

Standardize the plumbing. Publish interface specs for coolant and power. If every vendor uses the same quick disconnects and the same voltage rails, battalions can share spares and maintenance steps regardless of who built the laser box.

-

Train maintainers as early as operators. Send the first wave of 91 series maintainers through a laser sustainment course that covers power conversion, coolant handling, contamination control and optical care. Make it hands on with faulted components, not slide decks.

-

Buy time with hybrid tactics. Until every brigade has a laser platoon, pair one DE M‑SHORAD section with two kinetic M‑SHORAD sections. Put the laser where drone traffic is highest, and use the others to backstop with cannon and missiles. This reduces the number of missiles burned per week and buys breathing room for industry to deliver.

-

Sweep the supply chain. Pumps, sensors, and coolers need second sources. Use the competition to demand multi vendor parts where possible. Lock proprietary items behind published interface control documents so replacements slot in without software rewrites.

The bigger picture

The Army is not chasing lasers because they look futuristic. It is chasing them because they match the physics and economics of the threat. Drones are cheap, numerous and adaptable. The only way to win that exchange at scale is to bring the marginal cost of defense down and expand the number of shots available per mission. A 50 kilowatt class Stryker laser paired with a kinetic M‑SHORAD battery can do both, as long as the service treats power and thermal like ammunition.

The Fort Sill events were important for another reason. They turned a one time marvel into a playbook. Crews practiced how the radar hands a track to the camera, how the camera hands a lock to the laser, how the commander authorizes the shot, and how every step is recorded and replayed for training. That is doctrine in the making. The Enduring High Energy Laser competition in 2026 can be the hinge that swings the door from prototypes to battalion sets. If the Army keeps the scope tight, funds the spares early, and trains the maintainers with the same urgency as the gunners, brigade level laser coverage by 2027 is not a moonshot. It is simply the next fielding milestone on a path the service has already started to walk.

And when the next swarm rises over a treeline, the crew that has practiced the handoffs will not be thinking about buzzwords. They will pick the cheapest tool that works, fire it, and move. That is how a breakthrough becomes routine.