Navy CPS Test Starts the Clock for Zumwalt and Virginia

A successful May 2025 end-to-end CPS launch proved the Navy’s sea-based hypersonic approach. See why Zumwalt-class destroyers field first, how Virginia-class submarines follow, what it means for Pacific deterrence, and how to close the defense gap.

The test that moved sea-based hypersonics from slides to steel

On May 2, 2025, the U.S. Navy executed an end-to-end Conventional Prompt Strike, or CPS, launch that used the cold-gas shipboard ejection method the fleet plans to field. The event at Cape Canaveral was not just another hypersonic trial. It was the first full demonstration of the Navy’s sea launch approach for a common boost-glide round that will serve both the Army and the Navy. For a program that has had its share of postponements, a clean end-to-end cold-gas launch test signaled that the maritime piece is real and moving. The Navy declared the approach proven in an official release, and it is the reference point that starts the fleet’s clock for fielding on the water. See the Navy’s description of the end-to-end cold-gas launch test.

What made this test different is its fidelity to the deployed configuration. CPS uses a two-stage booster that lofts a Common Hypersonic Glide Body, often called the C-HGB. The Navy’s sea variant adds a canister and a cold-gas ejection sequence that pushes the canister clear of the ship before ignition, much like a submarine launching a missile from underwater. That sequence has to be boringly reliable, because a bad ejection is not a recoverable event at sea.

What fields first, and when

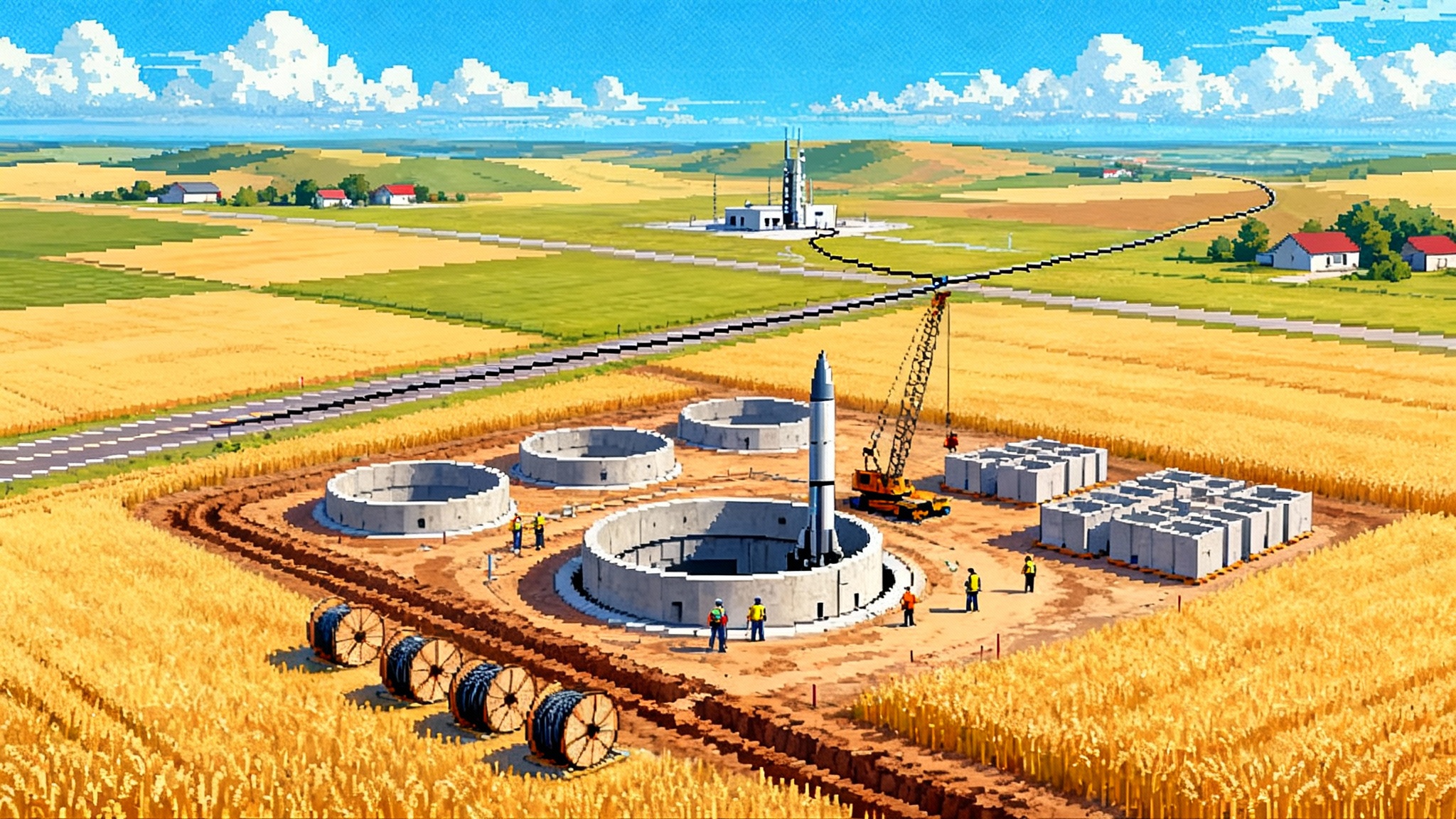

The Navy’s order of battle for sea-based hypersonics is clear. First are the three DDG-1000 Zumwalt-class destroyers. Each ship trades its now-orphaned 155 millimeter Advanced Gun Systems and a slice of bow structure for a set of large-diameter vertical launch tubes sized for CPS canisters. Navy and industry documents commonly call this the Large Missile Vertical Launch System, or LMVLS. Think of it as an extra-wide elevator shaft in the forward hull that accepts a canister as big around as a beach umbrella stand, not a soda can like a standard cell.

Each Zumwalt will carry multiple CPS canisters. Public imagery and program briefs point to four large-diameter tubes forward. Each tube can host a Multiple All-Up-Round Canister module, and each module holds several rounds. The exact ship loadouts will evolve as testing, safety margins, and maintenance concepts mature, but the headline is straightforward. Zumwalt becomes the first surface combatant with a magazine of hypersonic boost-glide rounds.

Next are Block V Virginia-class submarines, the boats that introduce the Virginia Payload Module, or VPM. VPM adds four very large payload tubes amidships to carry bulky weapons or clusters of cruise missiles. Those tubes give the Virginias the girth to host CPS canisters. The submarine integration problem is different from the destroyers: pressure hull interfaces, buoyancy changes, and shock isolation must be reconciled with stealth and patrol endurance. The payoff is tactical. A CPS-capable Virginia can sprint silently inside the seams of an adversary’s anti-access zones and hold high-value airfields, hardened command centers, or mobile anti-ship batteries at risk with little warning.

A realistic window, given shipyard schedules and testing cadence, is that a DDG-1000 conducts the first at-sea CPS firing before the end of this decade, with initial operational deployments following test shots. A Block V Virginia follows after that. This order matches both technical maturity and program momentum: the destroyers have hull space already opened for LMVLS, while the submarines need full weapon-in-module integration and certification.

What this does to the Pacific deterrence math

CPS does not just hit hard. It compresses time. Range measured in thousands of kilometers, plus sustained hypersonic speed and maneuver through the atmosphere, turn today’s long-distance no-go zones into tomorrow’s engagement areas. In the western Pacific, that means a U.S. surface combatant can posture outside the densest air defense umbrellas, receive a target-quality track from space or theater sensors, and launch a weapon that can arrive before an adversary can move a mobile battery or sortie aircraft. A CPS shot can cross the distance from the Philippine Sea to coastal launch sites in minutes, not hours.

That timing flips incentives. If an adversary believes its most valuable nodes can be destroyed quickly and precisely from the sea without warning, it must either disperse and harden far more aggressively, which strains logistics and readiness, or accept a first-mover disadvantage. Either choice changes the daily deterrence negotiation in U.S. favor. It also complicates coercion campaigns. A carrier strike group with a CPS-armed escort and a CPS-capable submarine in the theater does not need to steam into the heart of a contested zone to matter. Presence at the edge becomes presence with leverage, especially as aviation adds uncrewed partners such as carrier CCAs are go.

To take advantage of that leverage, the kill chain has to be ready before the missiles are. That means sensors that can hold dim, fast, and maneuvering targets in track, networks that move fire control data quickly, and commanders who can authorize shots at the speed of events.

The offense defense gap through 2028

The uncomfortable truth is that offense will field before the best defense. The Missile Defense Agency’s dedicated Glide Phase Interceptor, or GPI, suffered reduced funding and a downselect to a single contractor. Agency leadership has acknowledged a roughly three year slip against prior plans, with full operational capability directed by Congress for the early 2030s and deliveries stretching to the mid 2030s without more resources. Defense News summarized the change as a roughly three-year delay for GPI.

That leaves a window in which the fleet can shoot hypersonic boost-glide weapons from the sea, yet it cannot rely on a purpose-built glide phase interceptor to defeat adversary hypersonics in return. The Navy has tools today, notably the SM-6 family and Sea-Based Terminal capability against endgame threats, but those are partial answers. The glide phase is where hypersonic vehicles are hottest and most maneuverable, and it is exactly where GPI aims to work. Through 2028, commanders should plan for an offense-on offense competition at sea, with terminal defense as a narrow backstop rather than a guarantee.

The kill chain, accelerated

CPS usefulness depends on a kill chain that is fast, survivable, and repeatable. The parts are in motion, but they need a synchronized sprint:

- Space sensing. The Hypersonic and Ballistic Tracking Space Sensor, often abbreviated HBTSS, provides persistent custody of hard to track glide vehicles. The constellation needs enough satellites and ground processing capacity to create and maintain continuous tracks, not just detect launches, a goal that aligns with making responsive space operational at last.

- Air and maritime reconnaissance. P-8A Poseidon crews already fuse signals and imagery to hunt submarines; the same tactics apply to mobile launcher hunts. MQ-4C Triton can maintain broad-area maritime surveillance. E-2D Advanced Hawkeye brings high quality track correlation at sea. F-35 squadrons act as forward airborne sensors and shooters, feeding and receiving target tracks via Link 16 and other pathways.

- Machine-to-machine targeting. JADC2, the Pentagon’s Joint All Domain Command and Control initiative, is an abstraction that becomes real when a track created in space can trigger a CPS firing solution on a destroyer within a minute, with no human retyping required. That means common data models, latency budgets, and combat system software that accepts a target-quality track from off-board sensors without manual grooming, building on IBCS 2025 breakout moment.

- Command timelines and authorities. Hypersonic speed compresses decision windows. Fleet commanders will need standing targeting frameworks and preplanned responses that delegate release authority under defined conditions. A CPS shot should be a routine option inside an air wing’s strike plan time budget, not a bespoke event that consumes the entire watch floor.

The industrial ramp that must accompany the missiles

The CPS All Up Round is a supply chain in a canister. Lockheed Martin integrates the weapon system. Northrop Grumman and L3Harris Aerojet Rocketdyne are key solid rocket motor suppliers. Dynetics, working with Sandia National Laboratories, manufactures the Common Hypersonic Glide Body’s thermal protection and aeroshell structures. General Dynamics and Huntington Ingalls Industries adapt ship structures. The list is longer, but the bottlenecks are familiar.

- Thermal protection throughput. Ceramic matrix composites and high temperature ablatives cannot surge the way steel plate can. Setting up a second qualified production line for glide body thermal protection and leading edges will pay back schedule risk more than any one additional booster build station.

- Solid rocket motors. Large motor capacity in the United States is tight. A dual source approach for key motor segments, with shared tooling standards and government furnished equipment where appropriate, reduces single point failure risk. It also disciplines cost growth.

- Canister and handling gear. CPS is too large for standard missile elevators and storage. The fleet and the yards need purpose built pier side handling rigs, transporter-erectors, and training canisters so that loading CPS is as safe and scripted as loading Tomahawk.

- Test targets and ranges. Hypersonics require dedicated test windows over long distances. The Pentagon’s hypersonic test bed efforts and new range corridors must be funded as seriously as the rounds themselves, or program cadence will bog down behind scheduling conflicts.

VLS and integration hurdles at sea

Putting a large canister into a ship is as much naval architecture as it is weapon integration.

- Structure and shock. Cutting a new set of large launch tubes into a destroyer’s forward deck means restoring longitudinal strength and ensuring the bow can take green water without compromising the launchers below. The canister must ride through repeated slams and still eject on command. That calls for shock qualified mounts and careful attention to hull girder loads.

- Weight and balance. Replacing a gun with a launcher changes the ship’s center of gravity. Naval architects juggle ballast, fuel distribution, and equipment placement so that a destroyer still makes design speed and rides properly in heavy seas.

- Electromagnetic compatibility. A CPS firing sequence should not blank a radar or crash a combat system. Cables, grounding, and software timing must be set with real world electromagnetic interference measured, not guessed.

- Software. The combat system needs a CPS weapon module, not a work-around. That module must absorb off-board tracks, compute a firing solution, and manage a cold-gas ejection with precise interlocks. Reuse is good, but CPS adds new states and safety checks that are not found in legacy missile launch code.

- Submarine specifics. On Virginia, the VPM tubes sit inside the pressure hull envelope. Integrating a CPS canister therefore touches buoyancy, trim, acoustic isolation, and weapon shipping arrangements for long patrols. Fire control has to live inside a submarine’s tight human-machine loop, where every extra panel or checklist page matters.

A crash plan to close the counter-hypersonic shortfall

Glide Phase Interceptor will not save the fleet if it is not there. Through 2028, the most credible crash plan is layered and unsentimental.

- Double down on terminal shots. Increase procurement of SM-6 variants with software and seeker updates that improve late glide and terminal performance. Aegis Combat System baselines should prioritize hypersonic endgame logic and discrimination.

- Make space sensors operational, not experimental. Fund HBTSS follow-on launches and ground processing so commanders can request a track and get it in their combat system in near real time. That is the difference between an abstract constellation and an operational sensor.

- Expand cooperative engagement. Push sensor-to-shooter trials that connect Japanese Aegis destroyers, U.S. carriers, and land based radars so that the best placed shooter fires with the best available track, regardless of the crest on the hull. The mechanics exist today, the policy pathways and exercises need to normalize them.

- Add deception and soft kill. Decoys and signature management complicate hypersonic seekers that must commit to a final aim point under severe time pressure. Shipboard electronic attack and offboard active decoys that generate convincing aim points can create the extra few seconds an SM-6 needs.

- Harden the critical nodes. If a naval base, fuel pier, or airfield is the real prize for an adversary’s hypersonic salvo, build revetments, duplicate power runs, and preposition repair kits. The cheapest way to survive hypersonics is sometimes to be less fragile.

- Left of launch options. Cyber operations against fire control networks, and kinetics against mobile launchers using non-hypersonic weapons, reduce the incoming problem size. A small number of destroyed launchers is a large reduction in downrange intercepts required.

- Interim interceptors and timelines. If Congress wants a defense before 2032, it must provide the funding for parallel risk reduction and hot fire testing on a GPI path that accepts concurrency. A limited early capability on a few Aegis ships, even if range and kinematics are constrained, is better than waiting for the perfect solution.

A realistic checklist for 2026 to 2029

- Finish structural work and combat system integration on the lead Zumwalt, then execute a shipboard CPS firing event, not a pad shot, before the end of the decade. Use that shot to validate the full cold-gas to ignition sequence in sea state, not just in a calm test condition.

- Lock in submarine integration drawings early, then hold configuration discipline on the lead Block V Virginia that will carry CPS. The path to sea trials runs through design freezes, not perpetual tweaks.

- Treat the pier as part of the weapon system. Every homeport and forward site that will turn a CPS ship needs trained crews, certified handling gear, and a safe load plan. Without that, operational tempo will be throttled by logistics.

- Operationalize the kill chain in exercises. Run Pacific deployments where a carrier air wing, a P-8A detachment, space sensors, and a destroyer execute a full sensor to shooter flow against a realistic mobile target surrogate. Measure the minutes and remove the friction.

- Resource the supply chain choke points. Thermal protection systems and large rocket motors do not appear on short notice. Contract a second source, fund the tooling, and buy long lead materials early.

- Keep counter-hypersonic improvements in the annual fleet rhythm. Push Aegis baselines, SM-6 software refreshes, SPY-6 radar fielding, and HBTSS data paths on schedules that align with the first CPS deployment, not years later.

The bottom line

The May 2025 CPS demonstration changed the debate from whether sea-based hypersonics will work to how quickly the Navy can field them and how it will fight once they are aboard. Zumwalt-class destroyers lead the way, Virginia-class submarines follow, and the Pacific deterrence equation tilts as time-to-target collapses. The defense will lag offense for several years, which means commanders must plan layers that include space sensing, cooperative engagement, terminal shots, deception, and left of launch options. The to-do list is not glamorous. It is structure and software, handling gear and training, satellite downlinks and legal authorities.

If the Navy treats CPS like a system-of-systems that extends from the glide body to the pier crane to the satellite track, then the first shipboard shots will do more than flash across the sky. They will signal to friends and competitors that the fleet can create time where it wants it and take time away where it must.