PrSM Enters Production as the Army’s Deep-Strike Era Begins

With Milestone C on July 2, a $4.94 billion production vehicle on March 31, and IOT&E finished on September 26, 2025, the Precision Strike Missile shifts from promise to presence. Next up: a seeker for moving ships, allied co-fielding, and scale by 2027.

Three green lights, one year

In six months, the U.S. Army’s Precision Strike Missile moved from program momentum to production reality. The sequence is unusually clean for a major weapon: a multibillion-dollar production vehicle in March, a formal production decision in July, and the completion of Initial Operational Test and Evaluation in September.

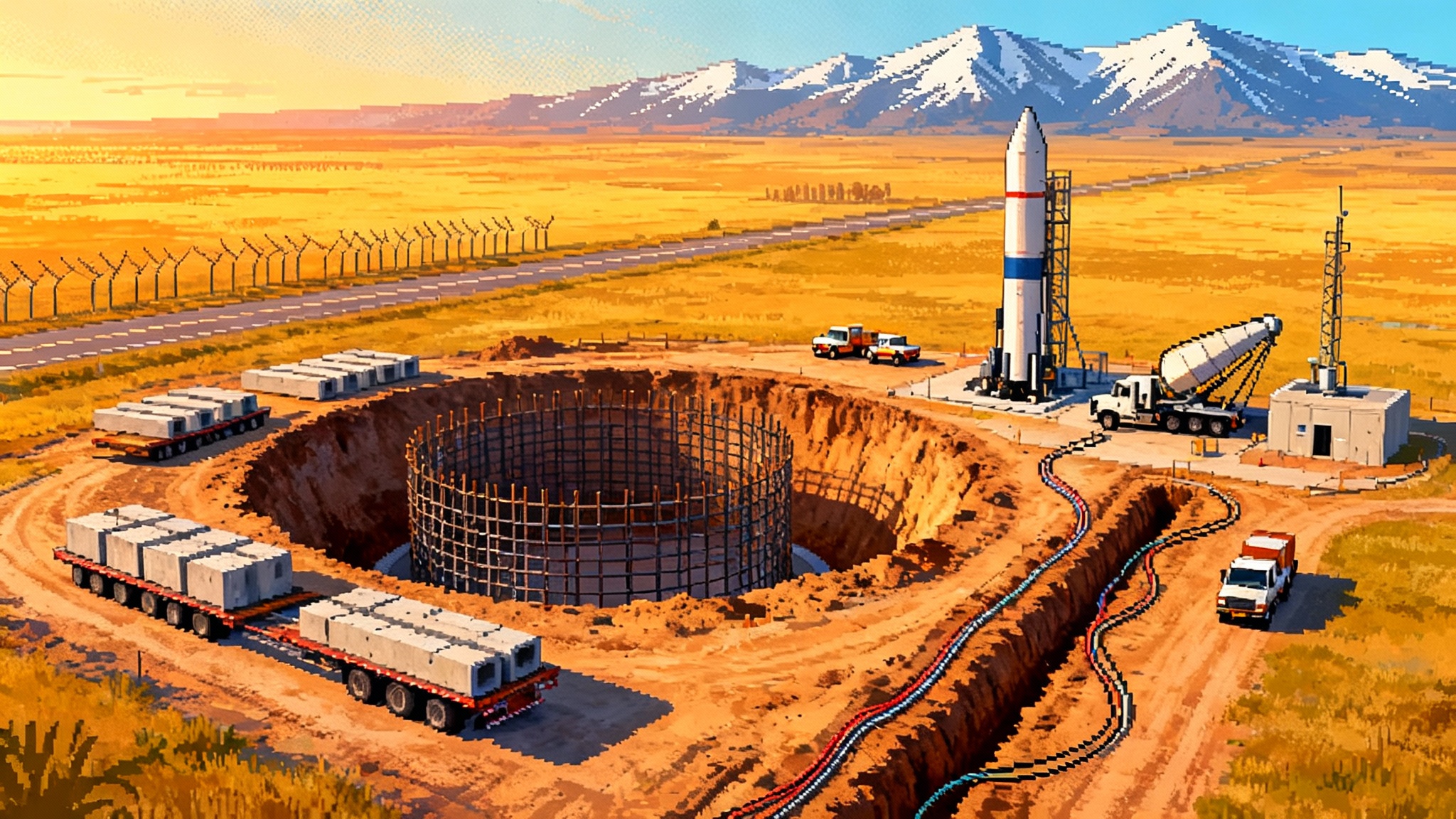

- On March 31, 2025, the Army awarded an indefinite delivery indefinite quantity production contract worth up to $4.94 billion to Lockheed Martin, establishing the financial ramp to buy missiles at scale.

- On July 2, 2025, the program cleared Milestone C, the acquisition gateway that authorizes Production and Deployment. The Army publicly confirmed that decision several days later; see the Army’s statement on the Milestone C approval on July 2.

- On September 26, 2025, soldiers at White Sands Missile Range finished Initial Operational Test and Evaluation (IOT&E). Four live missiles, fired from both M270A2 Multiple Launch Rocket System and High Mobility Artillery Rocket System launchers, met objectives for range, trajectory, accuracy, and height of burst. The Army published the IOT&E result on October 1; see the announcement of IOT&E completion on September 26.

Taken together, these steps signal a new reality for land power: routine, land-based precision strikes beyond 400 kilometers from mobile launchers that U.S. forces and many allies already operate.

What the Precision Strike Missile actually is

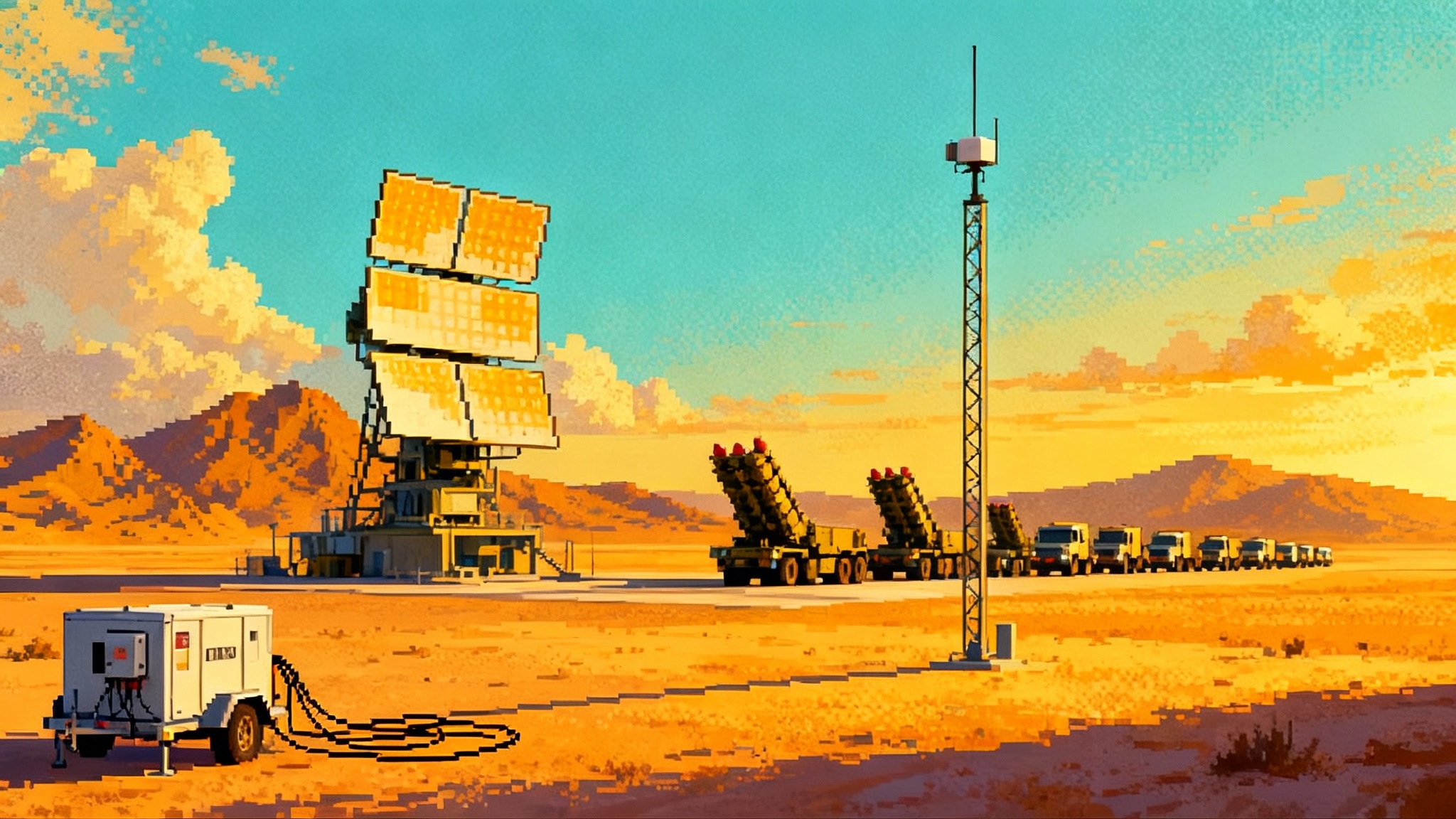

Precision Strike Missile, often shortened to PrSM, is the Army’s replacement for the Army Tactical Missile System. It travels farther than its predecessor, fits two missiles per launcher pod instead of one, and rides on launchers units already own: High Mobility Artillery Rocket System (HIMARS) and Multiple Launch Rocket System (MLRS). That combination gives commanders more reach, more shots per launcher, and no need to field a new vehicle.

Think of it as upgrading from a single-throw javelin to a compact, two-shot spear with a lighter shaft and better balance. The launcher is the same arm, the thrower is the same athlete. What changes is how far and how precisely the spear can fly, and how fast the thrower can line up the second shot.

Technically, Increment 1 is designed for fixed land targets at ranges greater than 400 kilometers. It uses inertial navigation refined by satellite navigation, plus a programmable height-of-burst fuze to tailor effects against different target types. Because it is built around an open systems architecture, the missile can accept new seekers and payloads without redesigning the airframe.

Why the 2025 decisions matter

Milestone C says the design is mature and the business case is sound. The $4.94 billion production vehicle matters because it lets the Army place orders on a schedule that matches both training needs and the industrial base’s ability to deliver. The IOT&E finish line matters because it confirms that soldiers can fire the weapon across the field conditions that paper rarely captures.

Put simply: the money turns on the factory lights, Milestone C opens the factory doors, and IOT&E proves the product behaves as advertised once it leaves the plant.

Production, parts, and the race to capacity

A precision missile is a supply chain in a cylinder. Rocket motors, case structures, navigation units, energetic materials, fuzes, cables, thermal batteries, software load devices, canisters, and test equipment all have to show up on time and in tolerance. The March contract sets a ceiling, but actual throughput will depend on bottlenecks like rocket motor casting queues, energetic fill cycles, thermal battery availability, and the specialized inspections that cannot be rushed without risk.

Three practical steps can accelerate throughput between now and 2027:

- Double-source the longest-lead items. Rocket motors and thermal batteries are classic pacing items. Bringing in a qualified second source, or at minimum parallel production lines under a single supplier, reduces the probability that one quality escape halts a whole lot. See related production context in our look at PAC-3 production surge insights.

- Fund surge tooling early. The hardest time to buy an extra winding mandrel, autoclave slot, or vibration table is when you already need it. Buying surge tooling during the first year of production protects 2026 and 2027 delivery months from cascading delays.

- Protect the test cadence. Live fire is not just a checkbox; it is process control for a complex product. Keep a predictable schedule for production qualification tests and lot acceptance tests, and feed results back into manufacturing within weeks, not quarters.

What Increment 2 and Increment 4 add

Increment 1 is about range, accuracy, and inventory. The next steps change what the missile can hit.

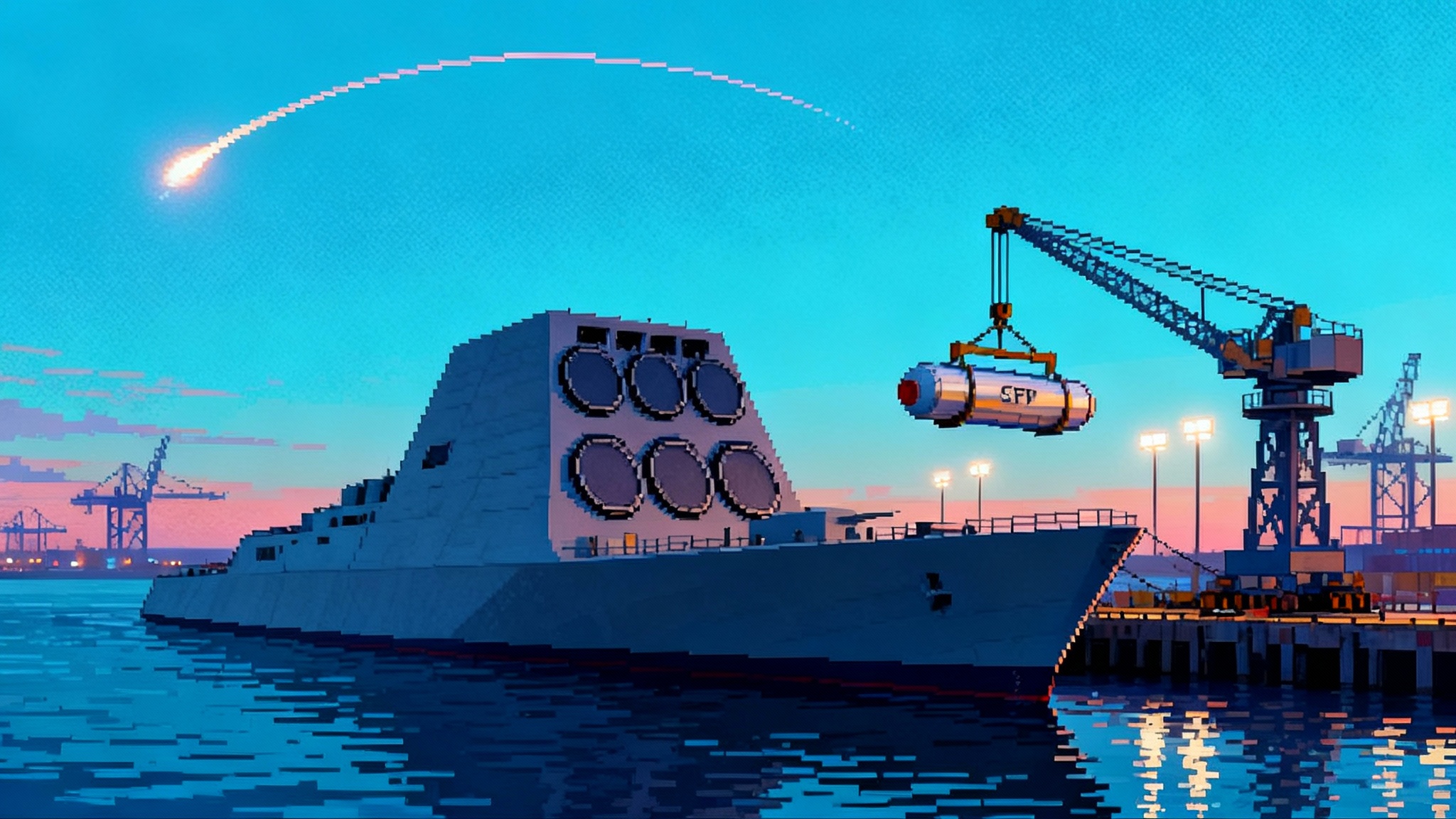

- Increment 2 adds a multimode terminal seeker designed to engage moving maritime targets and relocatable land targets. That means the missile can home in during the last segment of flight, rather than relying solely on preplanned coordinates. If testing holds in 2026, selected units could begin operational fielding as early as 2027.

- Increment 4 is being scoped for longer reach and a more capable seeker suite, combining radio frequency and imaging infrared, with an initial operational capability targeted around Fiscal Year 2030. The idea is straightforward: keep the two-per-pod advantage, fly faster and farther, and discriminate targets in a cluttered electromagnetic environment.

If Increment 1 is the long arm, Increment 2 and Increment 4 add the open hand and the grasp. They turn deep strike from preplanned point attacks into dynamic hunts for high-value targets that do not sit still.

Allies are already in the loop

Australia is the leading indicator. Canberra has moved quickly to acquire HIMARS, to cooperate with the United States on PrSM development and production, and to fire the missile on Australian soil. That matters for two reasons. First, it shows that an ally can align doctrine, ranges, safety rules, and data links quickly enough to conduct live fires well before full-rate production. Second, it previews how allied batteries might integrate into a joint kill chain that includes U.S. and partner surveillance aircraft, surface ships, and space-based sensors. For the regional architecture that will receive these batteries, see our take on the Guam missile shield kill web.

Other allies that already operate HIMARS or MLRS are natural candidates. Poland, Romania, the United Kingdom, and several Asia-Pacific partners have compatible launchers or are procuring them. The production vehicle’s scale and the modular design make allied buys easier to plan, since the missile does not demand a new launcher fleet or a bespoke training pipeline.

The kill chain is the real bottleneck

A long-range missile is only as useful as the network that finds, confirms, and updates the target. In the Pacific, that network spans ocean areas larger than the continental United States and includes dozens of actors. The core pieces are known by their acronyms, so let us define them clearly:

- Joint All-Domain Command and Control (JADC2) is a Department of Defense push to connect sensors and shooters across services through standardized data formats, resilient networks, and smart gateways.

- The Army’s Tactical Intelligence Targeting Access Node (TITAN) is a ground system designed to ingest space, air, and cyber intelligence and turn it into targets for Army shooters, including PrSM.

- Fire control systems such as the Advanced Field Artillery Tactical Data System (AFATDS) generate firing solutions and pass them to launchers.

Space-based sensing will be especially important to cue long-range shots. For the low Earth orbit layer that is arriving now, see the SDA Tranche 1 LEO network.

In practice, a PrSM shot against a moving warship or a wheeled missile launcher requires a chain that can see, decide, and update quickly. Maritime patrol aircraft, surface-search radars, small satellites, and undersea sensors can provide the initial detection. A second set of sensors confirms identity so the force does not strike the wrong thing. A third set provides updates in the final minutes so the missile’s seeker has a small box to search. The whole process has to survive jamming, cyber probing, bad weather, and the enemy’s own hunting.

That is why the seeker matters, but it is also why message standards and authorities matter. Units need prearranged permissions to accept target-quality data from joint and allied sensors. They need common time references and geodetic standards, and they need procedures that allow an allied maritime operations center to pass a track to an Army battery without a stack of phone calls.

The 2027 imperative

By 2027, Indo-Pacific commanders will want not just missiles, but a rehearsed, distributed concept of operations that turns PrSM batteries into reliable tools across a week-long crisis, not one-off demonstrations. That calls for specific moves now:

- Prepositioning and mobility. Store pods and canisters forward in climate-controlled sites and rehearse rapid sealift and airlift to island bases. Practice rearming launchers on small piers and short airstrips, not just at large depots.

- Mixed-launcher batteries. Blend HIMARS and MLRS in the same formations to complicate enemy targeting and to take advantage of different mobility profiles. Equip each battery with organic counter-drone defenses and camouflage, concealment, and deception kits.

- A common targeting playbook. Publish a joint, unclassified playbook that spells out message formats, timing rules, and positive identification standards for engaging moving maritime targets with land-based fires. This lets allies train with realistic data even when the most sensitive sources are not available.

- An exercise ladder. Use a three-rung progression for allies: simulated dynamic targeting; inert, captive-carry seeker profiles; then live seeker shots against instrumented barges or towed targets. Make the progression predictable so industry and ranges can plan the instrumentation.

- Sustainment under fire. Invest in forward repair for canisters, launch rails, and electronics. A missile program lives or dies by readiness of the parts that do not make headlines.

What success looks like next year, and the year after

In 2026, success looks like steady monthly deliveries against the March production vehicle, clean lot acceptance test results, and a drumbeat of training launches that replace anxiety with muscle memory. It also looks like seeker flight tests that steadily reduce the size of the terminal search box against moving targets.

In 2027, success looks like batteries that can displace 50 to 100 kilometers, set up in under 10 minutes, accept a joint track from an allied sensor, and launch two missiles per pod against a coordinate that was updated less than five minutes before firing. It looks like allied units that can plug into the same playbook, and like logisticians who can swap a canister in less than 20 minutes with a two-person crew and a light wrecker.

Risks worth watching

- Seeker maturity. Terminal seekers are unforgiving. Watch for test cards that combine sea state, clutter, and jamming; those are the ones that matter for Increment 2.

- Energetics and motors. The defense industrial base has finite motor casting and energetic fill capacity. Even a brief pause for a safety stand-down can ripple into months of delivery slips unless the program funds surge tooling now.

- Range access. Long-range shots demand big safety footprints. Coordinate now for Pacific and European range availability in 2026 and 2027 so test and training do not collide.

- Concurrency strain. Rolling upgrades while building hundreds of missiles is the right strategy, but it requires ruthless configuration control and clear retrofit kits for the field.

The bottom line

The Army did the hard administrative work in 2025 and earned the right to move fast. PrSM is no longer a prototype or a promise. It is a production program with money behind it, a positive production decision, and an operational test record in soldiers’ hands. The right next move is to keep the factory warm, push the seeker to maturity, and wire the targeting network so a launcher on a coral airstrip can take a maritime track from an allied aircraft and turn it into a hit.