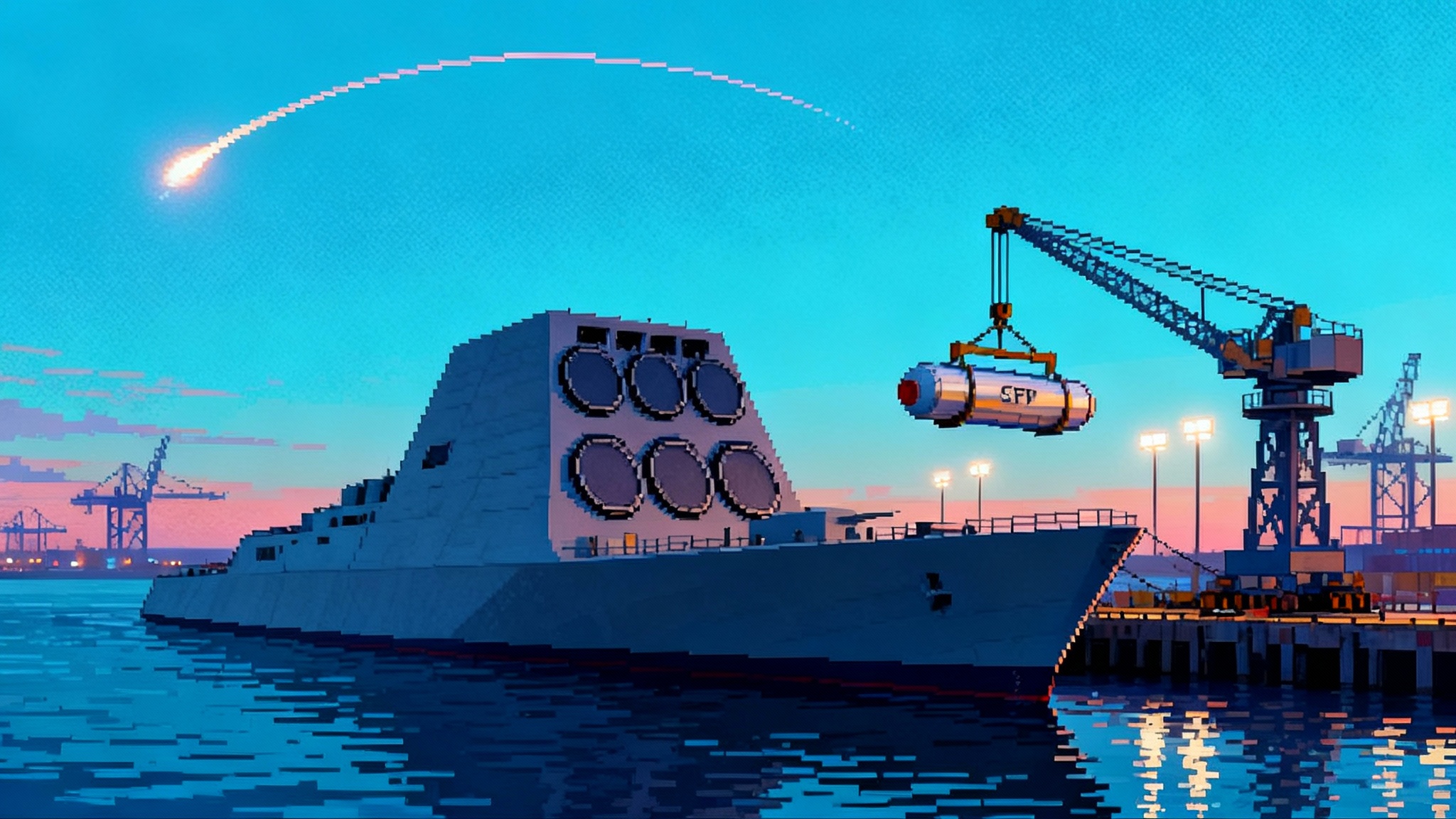

Sea-Based Hypersonics Get Real: CPS test and Zumwalt refit

In May 2025 the Navy validated cold‑gas ejection for Conventional Prompt Strike and is converting Zumwalt‑class destroyers to carry twelve common rounds. Here is what CPS is, what still blocks fleet fielding, and how this changes joint strike.

The breakthrough moment

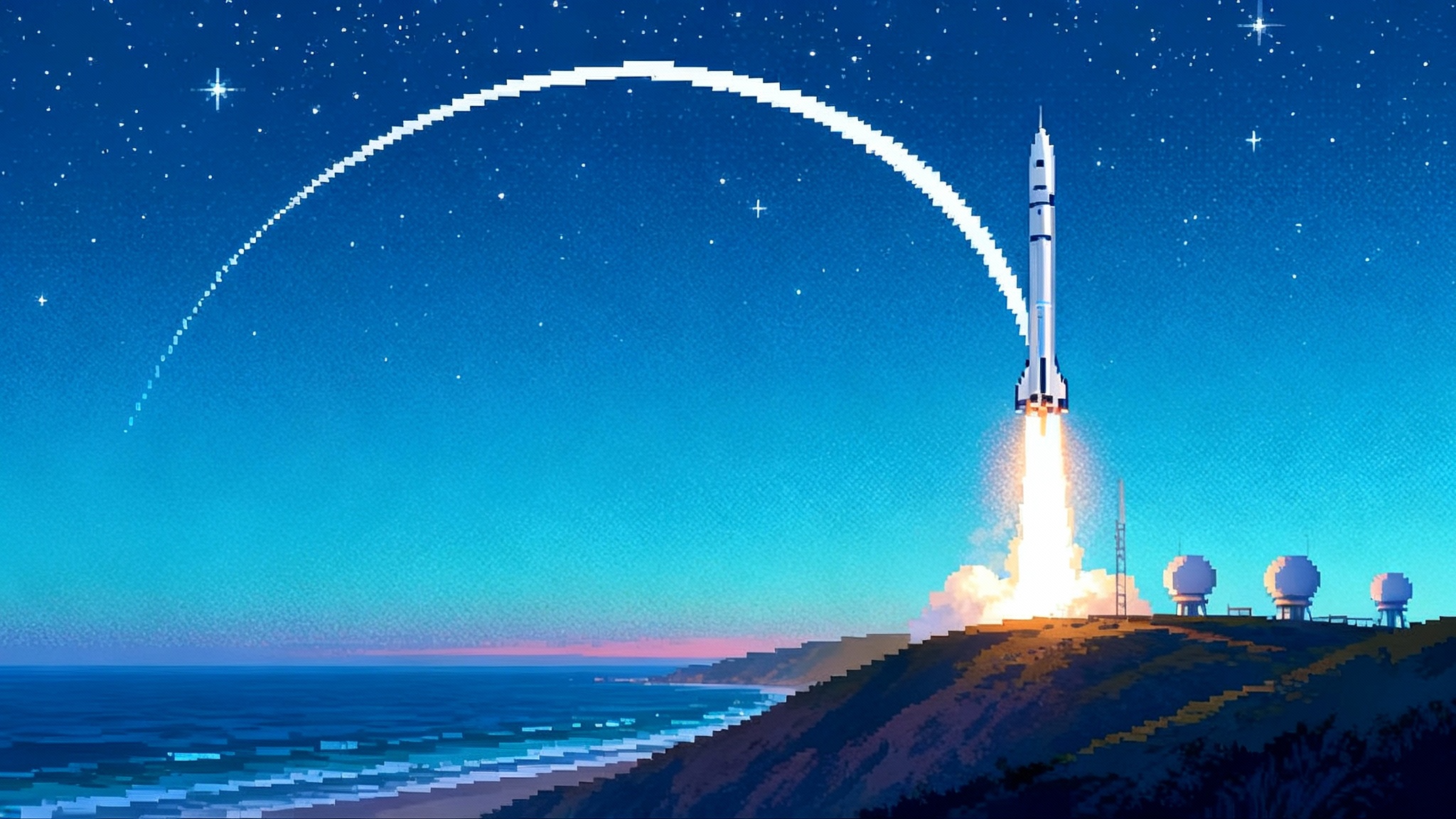

In May 2025 the Navy reported an end‑to‑end flight that validated its sea‑launch approach for Conventional Prompt Strike, proving cold‑gas ejection followed by safe booster ignition clear of the hull. That closes the critical engineering hurdle before ship and submarine trials and moves sea‑based hypersonics from concept to executable test planning. Navy validates sea‑launch approach.

CPS in plain language

Conventional Prompt Strike is a two‑stage solid booster that throws a wedge‑shaped Common Hypersonic Glide Body, which then rides the upper atmosphere at hypersonic speed and maneuvers to the aimpoint. The Army and Navy share the same all‑up round in a sealed canister, which means one industrial base, one test campaign, and a common playbook for joint fires.

Why the test matters now

After a string of delays, the Army resumed production for its first battery following a clean end‑to‑end flight in early fiscal year 2025. With the Navy’s sea‑launch method now demonstrated, the two biggest technical dominoes for the shared round are down, simplifying the path to at‑sea operational testing later this decade.

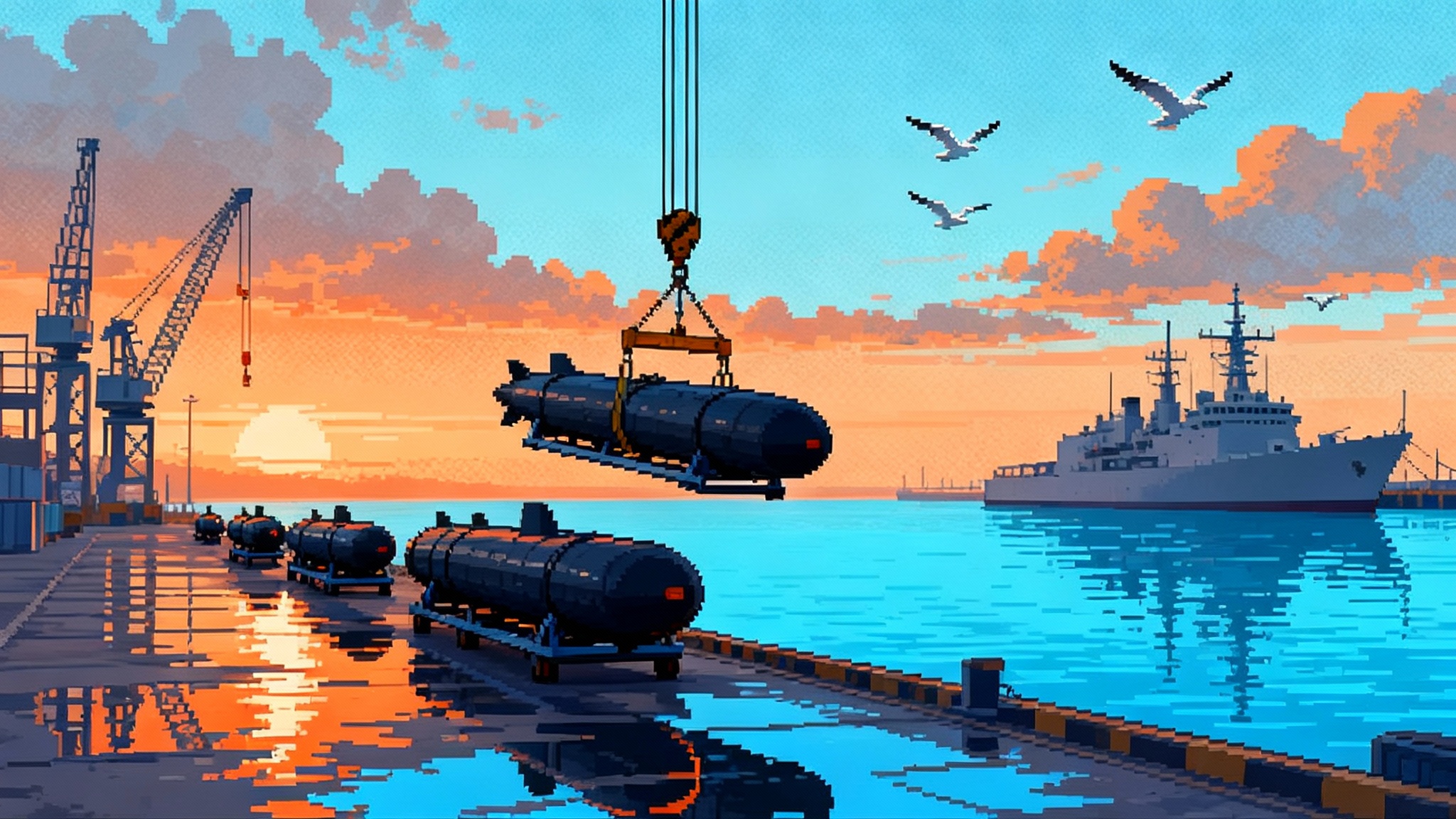

Inside the Zumwalt conversions

At Pascagoula the Zumwalt class is being transformed from an advanced‑gun ship into a hypersonic strike platform. The forward gun mount is replaced by four large‑diameter launcher modules. Each module carries a Multiple All‑Up Round Canister with three CPS rounds for twelve total shots. The refit includes new cold‑gas plumbing and upgraded combat‑system software for trajectory planning, weapon safety, and fire‑control. The Navy targets live‑fire from the first ship in the 2027 to 2028 window, with follow‑on conversions of the two sister ships queued for the back half of the decade.

The three blockers that matter now

Fielding at sea is a bundle of dependencies the fleet must close in parallel.

1) Targeting data that is good enough to shoot

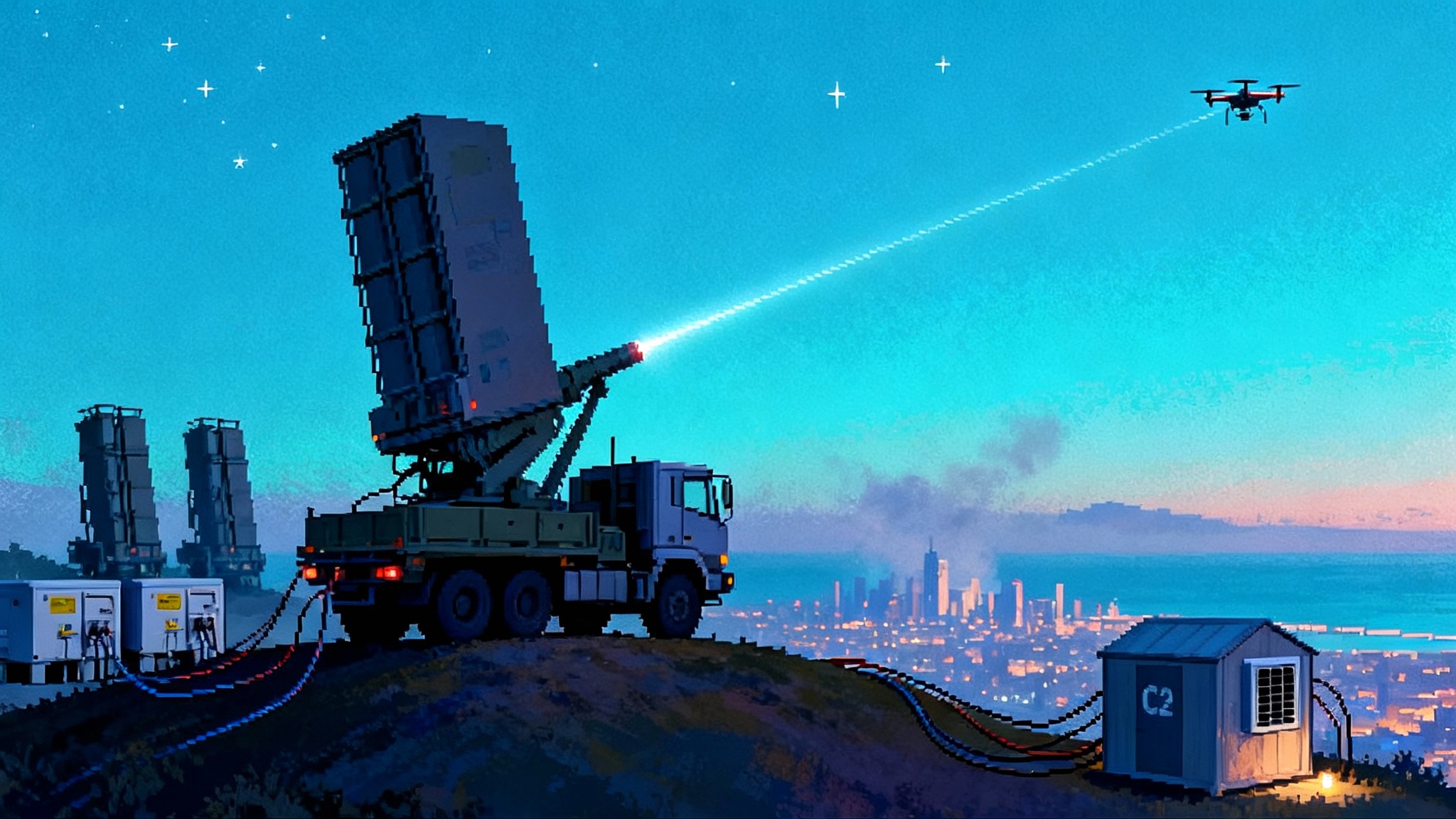

Hypersonic glide vehicles demand precise initial conditions and timely updates. The sensing and transport architecture is maturing through dedicated hypersonic trackers and a proliferated LEO backbone. As that LEO battle network arrives and scales, the mission moves from merely detecting to reliably aiming. /sdas-tranche-1-lifts-off-as-the-leo-battle-network-arrives

Action, why, how: treat space‑to‑sea connectivity as a fleet program of record. Resource shipboard integration kits and crew training now so early Zumwalt events ride operational data paths rather than bespoke test cables.

2) Ship modifications and combat‑system integration

Pulling a gun, adding four large tubes, and installing cold‑launch gear is major shipyard work, but the pacing item is software. Keep the first increment tight: the minimum set to shoot safely and accurately, then iterate as confidence grows.

Action, why, how: co‑locate ship combat‑system engineers with the weapon integrator at the yard to cut decision latency and reduce scope creep.

3) Munitions production and the industrial base

The shared all‑up round lives or dies on factory throughput across glide‑body thermal protection, large solid motors, canisters, and electronics. The broader U.S. missile sector is surging, but skilled labor and long‑lead materials remain constraints. See how multi‑year buys and supplier investments are being unlocked in the wider missile production surge. /pac-3-mega-order-and-the-us-missile-production-surge

Action, why, how: place multi‑year contracts for the round and thermal protection, fund advance procurement on a predictable drumbeat, and stand up joint Army‑Navy quality‑escape boards so fixes propagate once.

How a common round changes joint strike

When the munition is common, the joint force can standardize telemetry, safety analysis, and crew procedures. That accelerates feedback loops between land and sea testing and strengthens the emerging joint kill web that connects sensors, networks, and shooters across theaters. /guams-2025-missile-shield-pivots-to-a-joint-kill-web

The Indo‑Pacific math if the plumbing arrives

Range is the signature advantage. Public reporting pegs the shared round’s reach around 1,700 miles, allowing a single ship in the Philippine Sea to threaten time‑sensitive targets deep inside anti‑access belts. As space sensors maintain custody and transport layers push targeting updates in seconds, ships and Army batteries firing the same round can present multi‑axis, minutes‑to‑impact dilemmas that force dispersal and drive up the defender’s cost. Virginia‑class submarines with future payload modules will add a stealthy magazine at sea once attack‑sub production recovers.

What to accelerate now

- Build space‑to‑sea data paths into fleet exercises and use real Link 16 message formats during live events to train crews under operational stress. See the recent space‑to‑ground Link 16 transmission milestone. SDA demonstrates space‑to‑ground Link 16

- Fund a Zumwalt software tiger team with ship, weapon, and sensor engineers co‑located to shorten integration cycles while hardware is open and accessible.

- Lock in multi‑year buys for the all‑up round, thermal protection, and canisters, with award fees tied to first‑pass yield so schedule does not outrun quality.

The bottom line

Sea‑based hypersonics are no longer theoretical. The Navy has proved its launch approach for CPS, the Army has restarted production after a clean test, and the first Zumwalt is back in the water with new launchers that will hold twelve common rounds. Finish the data plumbing, complete ship integration, and scale factories, and the United States will enter the late 2020s with a joint hypersonic strike web that compresses an adversary’s options before they can respond.