Sentinel’s new-silo pivot: America’s biggest defense build

The Air Force’s decision to build hundreds of new ICBM silos turns Sentinel from a missile recapitalization into a five-state civil-works megaproject. Here’s what broke reuse, where the real chokepoints are, and how to move faster without sacrificing nuclear surety.

Breaking: the missile program that became a construction program

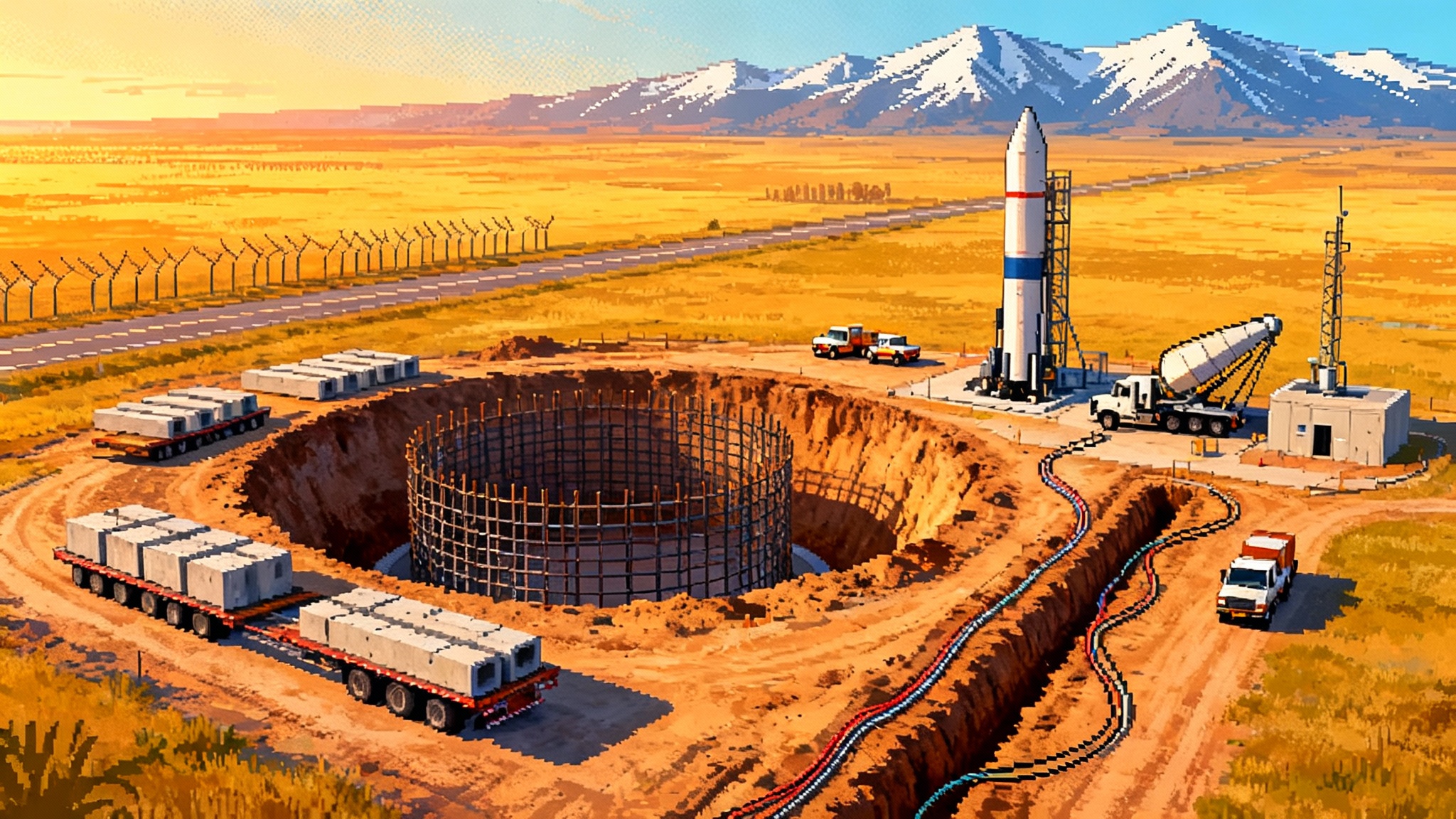

The most consequential change in United States nuclear modernization this year did not come from a warhead lab or a missile factory. It came from a decision about dirt and concrete. In May, the United States Air Force shifted away from retrofitting half‑century‑old Minuteman silos and toward building hundreds of brand‑new launch facilities for the LGM‑35A Sentinel. That choice reframed a weapons recapitalization as a five‑state civil‑works mega‑project.

Two developments put urgency behind the pivot. First, the Government Accountability Office warned in September 2025 that delays and the absence of a formal transition risk plan could push the Air Force to operate Minuteman III well into the 2050s, with mounting sustainment hazards and parts obsolescence. GAO called for concrete actions to manage the handover, highlighting a need to tie risks to milestones and accountable owners. See the GAO September 2025 report.

Second, after trial work converting a test launch facility at Vandenberg, the Air Force concluded that reusing Cold War‑era silos created unacceptable cost and schedule risks. The service said it will construct new missile silos, largely on Air Force‑owned sites in the existing missile fields, rather than trying to adapt 55‑year‑old structures. As one official summary put it, reuse looked efficient on paper but failed in the dirt. The Air Force to build new silos.

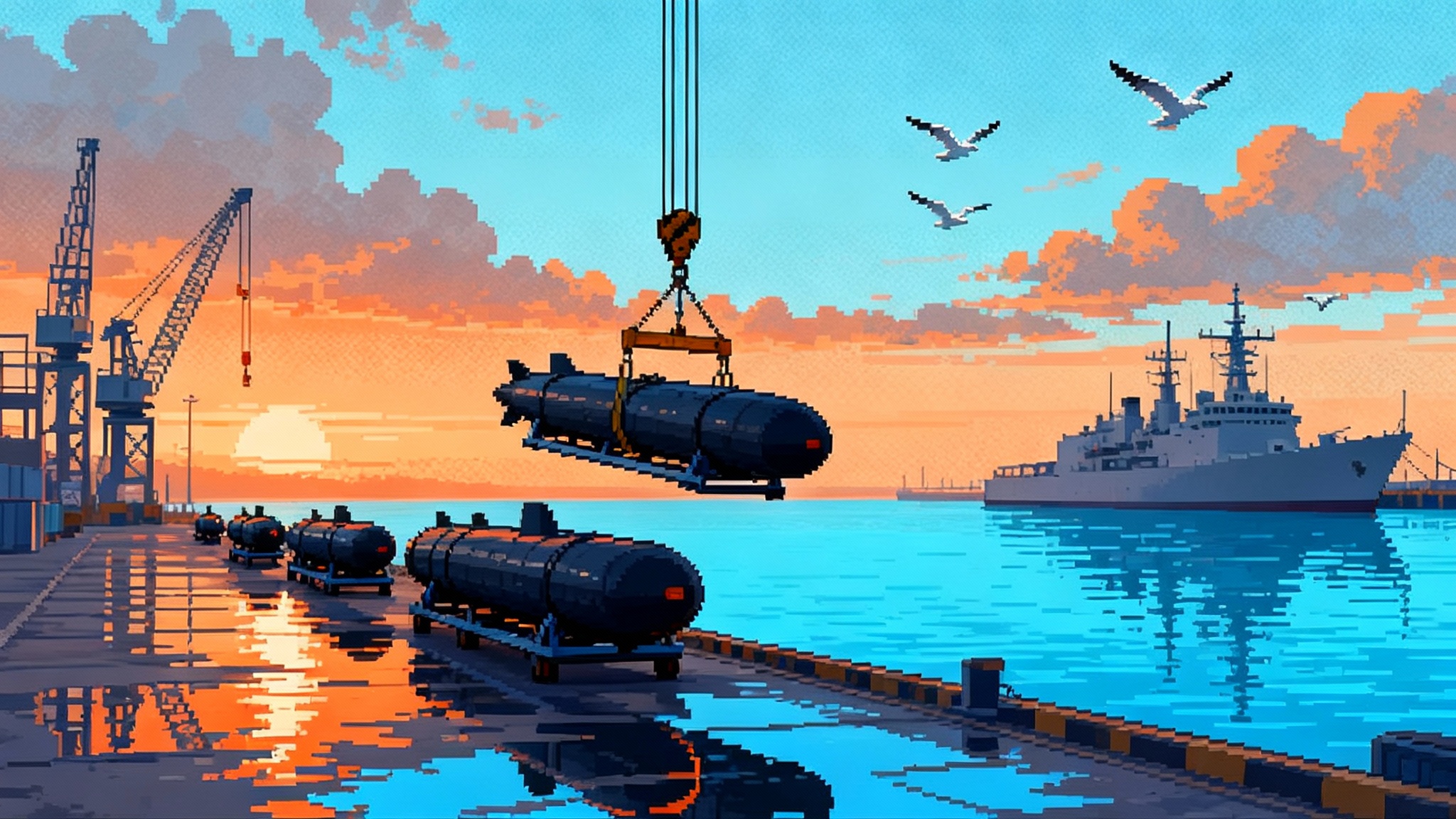

If you picture Sentinel as a line of missiles on a factory floor, this news is disorienting. A better image is a utility overhaul stretched across the Great Plains: thousands of miles of access roads, power upgrades, communications trenches, hardened nodes, and hundreds of pits drilled, lined, and outfitted to exacting tolerances. The missile becomes one critical package among many. The schedule moves at the speed of excavation crews, precast yards, electricians, fiber splicers, and inspectors.

Why reuse failed, and what the pivot fixes

Reusing Minuteman silos sounded thrifty and quick. In practice it ran into three stubborn realities.

-

Unknown sub‑surface conditions. Each Cold War site has its own history of repairs, corrosion, water intrusion, and undocumented work. The Vandenberg conversion trial revealed that bringing an old hole up to modern nuclear surety and safety standards is not a clean upgrade. It is an archaeological dig that explodes both cost and time.

-

Geometry and loads. New blast doors, cableways, environmental systems, and the missile interface itself demand different geometry and tolerances. Trying to conform modern hardware to old concrete becomes a bespoke craft job at every location, the opposite of standardization.

-

Regulatory resets. Once a legacy facility is opened up, modern environmental, seismic, and safety codes apply. That turns each rehab into a major remediation project that burns dollars without pulling the schedule left.

The new‑silo decision tackles all three. It allows a standard design that can be repeated hundreds of times. It lets crews sequence work in parallel and leverage modern construction methods. It shifts the risk from the unknowns of old structures to the knowns of well‑planned civil works.

The three real chokepoints

Sentinel’s pivot does not dissolve risk. It concentrates it. Think of three bottlenecks that will decide the timeline.

1) Silo and launch facility construction

The heart of the program is not the missile. It is the launch facility: a deep, reinforced concrete structure with precise tolerances, integrated power, climate control, security, and shock isolation. Now multiply that by hundreds, spaced across remote terrain, in harsh winters and short construction seasons. The practical constraints are concrete batch capacity, specialty rebar and liners, drilling and shoring equipment, and a workforce of cleared heavy‑civil trades who can rotate across three missile wings.

Specific constraints to watch:

- Seasonal windows. North Dakota and Montana freeze. Pouring and curing high‑spec concrete in winter requires tenting, heating, and schedule slack.

- Batch plant proximity. Every additional mile from batch plant to pour steals strength margin. Mobile batch plants and on‑site quality labs are not nice‑to‑haves. They are schedule insurance.

- Specialty crews. There are not many electricians, riggers, millwrights, and fiber splicers with active clearances who have also worked in hardened facilities. Training pipelines and badging timelines are part of the critical path.

- Inspection cadence. Nuclear surety requires independent inspection at numerous hold points. If inspectors are booked or travel is slow, work waits.

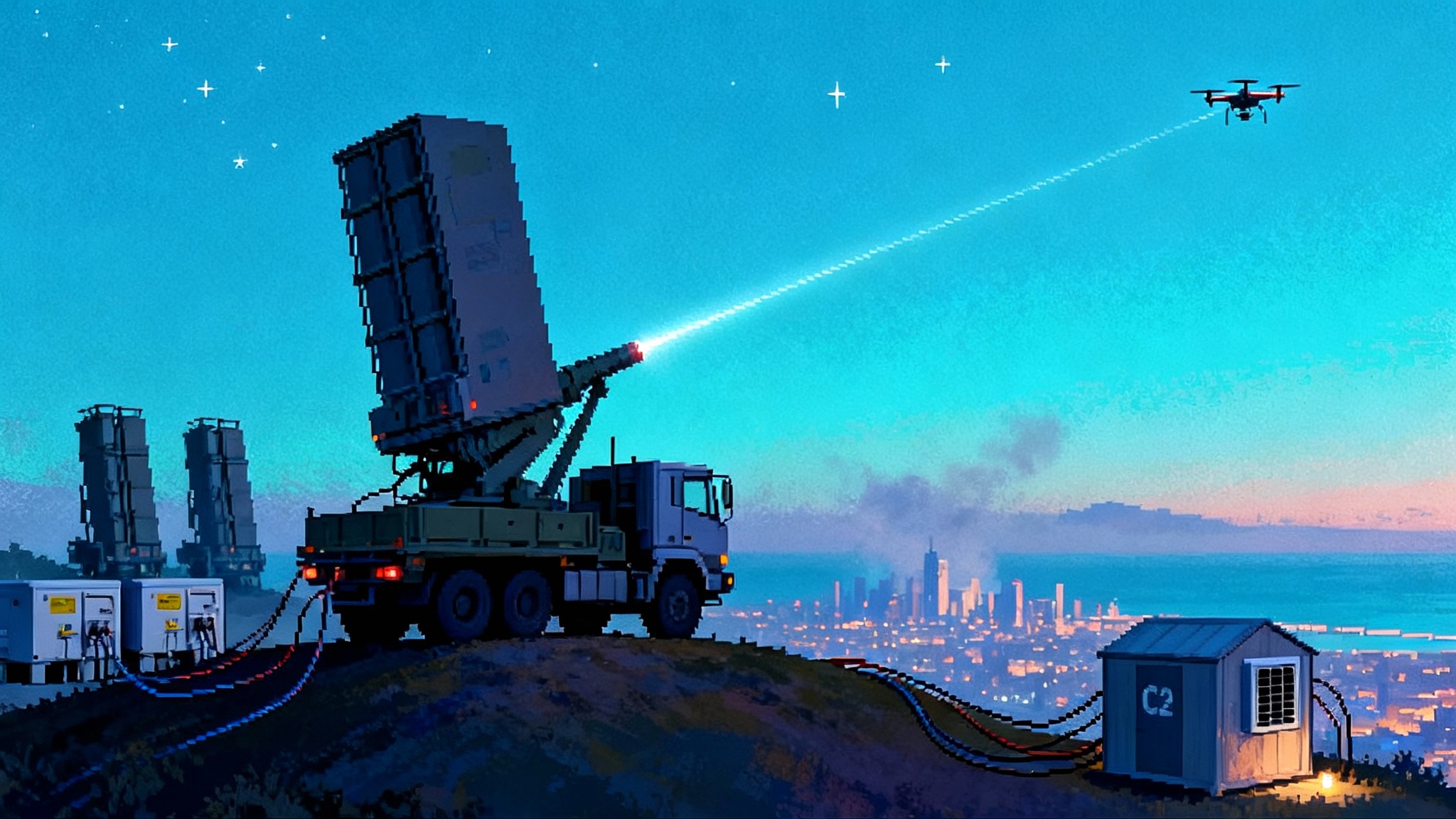

2) Hardened command, control, and communications

Command, Control, and Communications, often shortened to C3, is the nervous system. Buried fiber routes, hardened nodes, electromagnetic protection, secure power, and redundant paths must be built, tested, and certified before a single missile moves. These networks cross counties, private lands, and old rights‑of‑way. The chokepoints are trenching permits, easements, specialty materials like armored fiber and waveguide, and qualified crews who can document every splice to nuclear surety standards. Recent IBCS plug‑and‑fight progress shows how disciplined integration shortens risk.

3) Solid rocket motors and guidance supply chains

Missiles need rocket stages and guidance that are consistent, predictable, and traceable. The United States industrial base for solid rocket motors is small and brittle. Northrop Grumman and Aerojet Rocketdyne, now part of L3Harris, anchor the market, but their upstream suppliers for propellant chemicals, cases, nozzles, and insulation are narrow. Rad‑hardened electronics and high‑grade inertial measurement units have similar fragility. The bottlenecks are not only factories. They include the casting, cure, and acceptance test cycles that cannot be rushed without losing reliability. Lessons from the PAC‑3 production surge apply directly: long‑lead buys, parallel qualifications, and stable demand signals.

The risk of an extended Minuteman III era

GAO’s 2025 public report surfaced a scenario that used to be whispered: Minuteman III staying in service into the 2050s. That would be two more decades for a missile first fielded when rotary phones were still common. The availability risks are tangible.

- Cannibalization and diminishing sources. You can only harvest so many usable parts from retired missiles. Some components have no current commercial analogs. Recreating them means building cottage industry capacity for items that will be produced in the dozens.

- Flight test credibility. The deterrent message depends on demonstrated performance. Flight tests compete with operational needs, weather, and range availability. A stretched life makes consistent testing more important and more difficult.

- Hidden corrosion and material aging. Elastomers, sealants, and wiring harnesses age in ways that are hard to model. The cost is not only dollars. It is uncertainty that creeps into planning.

If Sentinel’s fielding moves right on the calendar, a prudent hedge is to treat Minuteman life extension as a real program, not a contingency. That means formal budgets, clear engineering owners, and a test plan that maintains credibility.

Accelerants that do not trade away nuclear surety

Pulling a program left in time without sacrificing surety is not magic. It is disciplined design, industrial standardization, and ruthless focus on the critical path. Here are accelerants that can work.

1) A standard launch‑facility package with factory discipline

Freeze a single, fully specified launch facility design with named materials, certified vendors, and preapproved deviations. Package it like a kit aircraft. Every site gets the same drawings, the same bill of materials, and the same quality assurance plan. Where terrain forces changes, limit choices to pre‑cleared options. The goal is not to eliminate engineering. It is to eliminate ad hoc engineering.

How to do it:

- Establish a configuration control board with voting seats for the Air Force, the prime contractor, and the construction integrator. No field change proceeds without a schedule and cost impact statement.

- Prequalify regional subcontractors against the package. Run mock builds at a dedicated training pad so crews arrive on site already fluent in the sequence.

2) Precast and modular construction

Switch as much as possible from cast‑in‑place to precast and modular assemblies. Think of vault segments, cable trays, stair towers, duct banks, and even sections of the silo liner fabricated in controlled yards, then trucked and set. Factory conditions yield better quality and faster cycle time than a winter pour in the wind. The Replicator program’s scaling lessons underscore how standardization and rhythm beat heroics.

How to do it:

- Stand up or contract dedicated precast yards near each missile wing. Validate curing, testing, and traceability once, then repeat.

- Use heavy hauls and staged laydown yards to feed a rolling wave of sites. The rhythm matters more than the single best day at any one site.

3) Digital twin oversight that spans primes and civil contractors

Model each launch facility, communications route, and power run as a living digital twin. Tie it to schedule, cost, materials traceability, weld logs, concrete cylinder breaks, and inspection sign‑offs. The digital twin is not a pretty visualization. It is the single source of truth that lets program leaders see which pour or splice will cause a month of downstream drag.

How to do it:

- Require machine‑readable submittals from every tier, including small civil subs. Provide a common data environment and low‑friction tools for the smallest players.

- Integrate factory acceptance tests for rocket stages and guidance units into the same dashboard. When a nozzle batch slips, the launch facility sequence should reflect the impact within hours.

4) Streamlined permitting with programmatic agreements

The Environmental Impact Statement for Sentinel work sets a baseline, but hundreds of local permits and approvals remain. Treat them as a portfolio. The play is to negotiate programmatic agreements with state and county authorities, tribes, and State Historic Preservation Offices that define standard mitigations and preapproved methods for recurring work like trenching, blasting, and road improvements.

How to do it:

- Create a permitting strike team that works six to nine months ahead of construction. Their output is a cleared map that crews can build against without pause.

- Use template easement language, pre‑negotiated with utilities and landowners. Make payments predictable and fast. Avoid bespoke legal wrangling at every fence line.

5) Industrial base moves that actually add capacity

Money does not automatically produce more solid rocket motors or rad‑hard gyros. Capacity comes from earlier orders, more qualified lines, and stable work for the small shops that make liners, nozzles, cases, and adhesives.

How to do it:

- Place long‑lead orders for propellant ingredients and cases now, with options to flex delivery windows. Pay for surge tooling where a second qualified line is feasible.

- Fund cross‑qualification of critical parts across Northrop Grumman and Aerojet Rocketdyne where security rules allow, and qualify alternate suppliers for nozzles and insulation. Tie milestone payments to first‑article acceptance, not only to delivery.

- For guidance, lock in multiyear buys with suppliers of inertial sensors and rad‑hard processors. Support domestic foundry and packaging capacity with predictable demand, not one‑time grants.

6) Workforce pipelines that match the map

There is no schedule without people. The work is rural. The prospective workforce lives hours away.

How to do it:

- Partner with union apprenticeship programs and community colleges to run accelerated, clearance‑compatible training in Cheyenne, Great Falls, and Minot. Offer per diem and rotational housing to keep crews on site.

- Use staggered shifts and winter work packages that focus on indoor or sheltered tasks so the calendar does not freeze when the ground does.

Keeping nuclear surety at the center

Nuclear surety means the weapons are safe, secure, and reliable. Moving faster cannot mean cutting corners. The right approach is to harden the gates rather than slow every step.

- Gate 0: design freeze with independent red‑team review of the launch facility package.

- Gate 1: vendor qualification for every precast element, with destructive tests documented in the digital twin.

- Gate 2: on‑site hold points where independent inspectors witness critical work like liner placement, cable terminations, and blast door installation.

- Gate 3: integrated systems tests that simulate alert conditions before any asset goes on status.

The discipline is to push decisions as far upstream as possible and to make every downstream step routine and inspectable.

Organizing for a civil‑works fight

The program will move at the speed of its least coordinated player. Today, a prime integrator builds the missile and leads the weapon system, while dozens of heavy‑civil contractors pour and wire the ground enterprise. What is missing is a construction general manager role, integrated with the prime but focused on the field.

- Charter a joint program office that pairs the prime contractor with a top‑tier civil integrator. Give it authority to sequence crews and allocate scarce equipment across wings based on the digital twin.

- Establish a rolling 12‑week look‑ahead that aligns factory deliveries, precast yard output, permits, inspector travel, and weather forecasts.

- Publish a simple, ruthless set of metrics: ready‑to‑pour sites per week, inspection pass rate on first attempt, splice defect rate, and miles of hardened fiber installed.

What a realistic path looks like

With the new‑silo pivot, success depends less on a single heroic milestone and more on steady velocity across many fronts. A feasible trajectory looks like this:

- Year 1 after restructure: finalize the standard launch facility package, stand up precast yards, and complete programmatic agreements in the three missile wings. Field the digital twin and onboard every subcontractor.

- Year 2: reach a drumbeat of multiple sites in parallel per wing, with first articles installed for blast doors, liners, and hardened communications nodes. Validate the inspection gates with no major rework.

- Year 3: sustain a rolling wave where one site reaches mechanical completion each week across the enterprise, while the missile side validates stage acceptance and guidance in parallel. Begin limited transitions from Minuteman facilities where civil work has proven out.

This is not a promise. It is a pattern that aligns the work with the way complex civil programs win.

The bottom line

The United States did not set out to make its largest defense civil‑works project when it green‑lit Sentinel. Yet that is what the 2025 pivot created. The risks are no longer abstract debates about future missiles. They are the very real constraints of concrete, cables, and crews, visible in weather windows and truck schedules.

The good news is that these are solvable problems. Standardize the design. Build in factories as much as possible. Use a digital twin to see bottlenecks before they bite. Streamline permitting across the entire map. Buy long‑lead parts early and qualify second sources. Train and house the people who will pour and wire the future.

If leaders treat Sentinel like a utility overhaul rather than a boutique weapons program, the calendar will move. And if they keep nuclear surety as the nonnegotiable center, the country will gain something rare in complex programs: speed with confidence.