Automation Hits the Arsenal: Inside the 2025 Factory Surge

New U.S. ammo plants and automated missile lines announced in 2025 mark a pivot from bespoke manufacturing to software defined factories. Here is how they can compress lead times by 2026 and what still blocks true surge.

The week the shell lines woke up

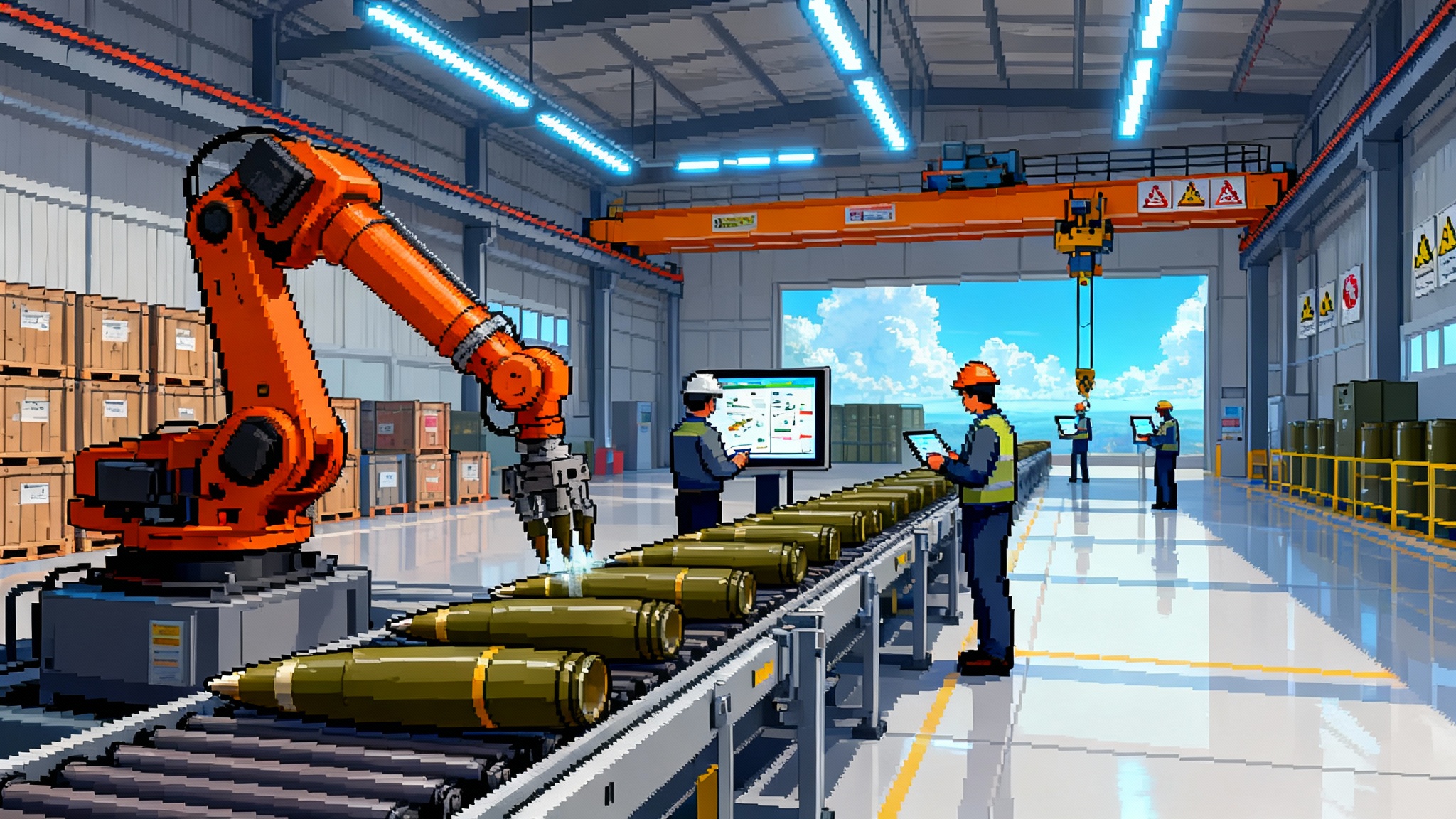

It has been a long time since munitions plants made front-page news. That changed in 2025. In April 2025 the Army and General Dynamics opened a new Camden load, assemble and pack facility designed to streamline 155 millimeter artillery production and push output toward six figures per month once fully online.

The news kept coming. In August 2025 the Army greenlit a Future Artillery Complex at the Iowa Army Ammunition Plant to enable scalable, reconfigurable load, assemble and pack operations. And on September 3, 2025, the Army awarded a multiyear PAC-3 MSE contract to Lockheed Martin, pairing record deliveries with plans to push annual interceptor output beyond historical peaks.

If 2025 was the wake-up year, 2026 is when the new playbook takes over: software defined, modular production guided by digital twins and artificial intelligence for quality, and robots designed to be moved, not cemented to the floor.

What software defined, modular production really means

Most readers know the feel of a well-run kitchen: standardized stations, prepped ingredients, digitized recipes and a line that flexes during the rush. A modern munitions plant is moving toward the same model:

- Software defined means work instructions, machine parameters and inspection rules live in code that updates across a line in minutes. Toolpaths, dwell times and cure profiles are controlled by a central recipe instead of binders.

- Modular means interchangeable cells. A robotic pick-and-place that loads shell bodies today can be rolled to another bay and retaught to handle a different projectile with a vision routine tomorrow.

- Integrated quality means computer vision checks every surface, inline metrology tracks wall thickness and threads, and each part carries a time series of measurements so defects become patterns, not mysteries.

Digital twins and AI quality assurance, in plain English

A digital twin is a living model of the factory that stays synchronized to the real one. Think of a video game version of the plant where you rearrange cells, change recipes or add a shift and see how queues and quality react before touching a wrench.

- For artillery, a twin can simulate explosive fill temperature profiles for M795 shells across seasons or test how a new sealant affects leak rates.

- For missile motors, a twin of the casting process can predict voids in propellant and nudge a robot to slow its pour or adjust vibration in real time.

Two enablers make this credible now: cheaper, more reliable sensors streaming torque, temperature and dimensions into the model, and machine learning that flags patterns across millions of data points in minutes.

Bending cost curves by 2026

Cost in munitions is dominated by three levers. Software defined, modular lines attack all three:

- Touch labor falls when robots handle repetitive, hazardous work. People shift to supervising multiple cells and solving exceptions.

- Rework and scrap drop because AI quality catches issues mid-cycle. A marginal thread or misaligned crimp triggers an immediate recipe tweak.

- Capital utilization rises because common cells run more often. Changeovers that once took days can shrink to hours when fixtures and inspection algorithms are planned together.

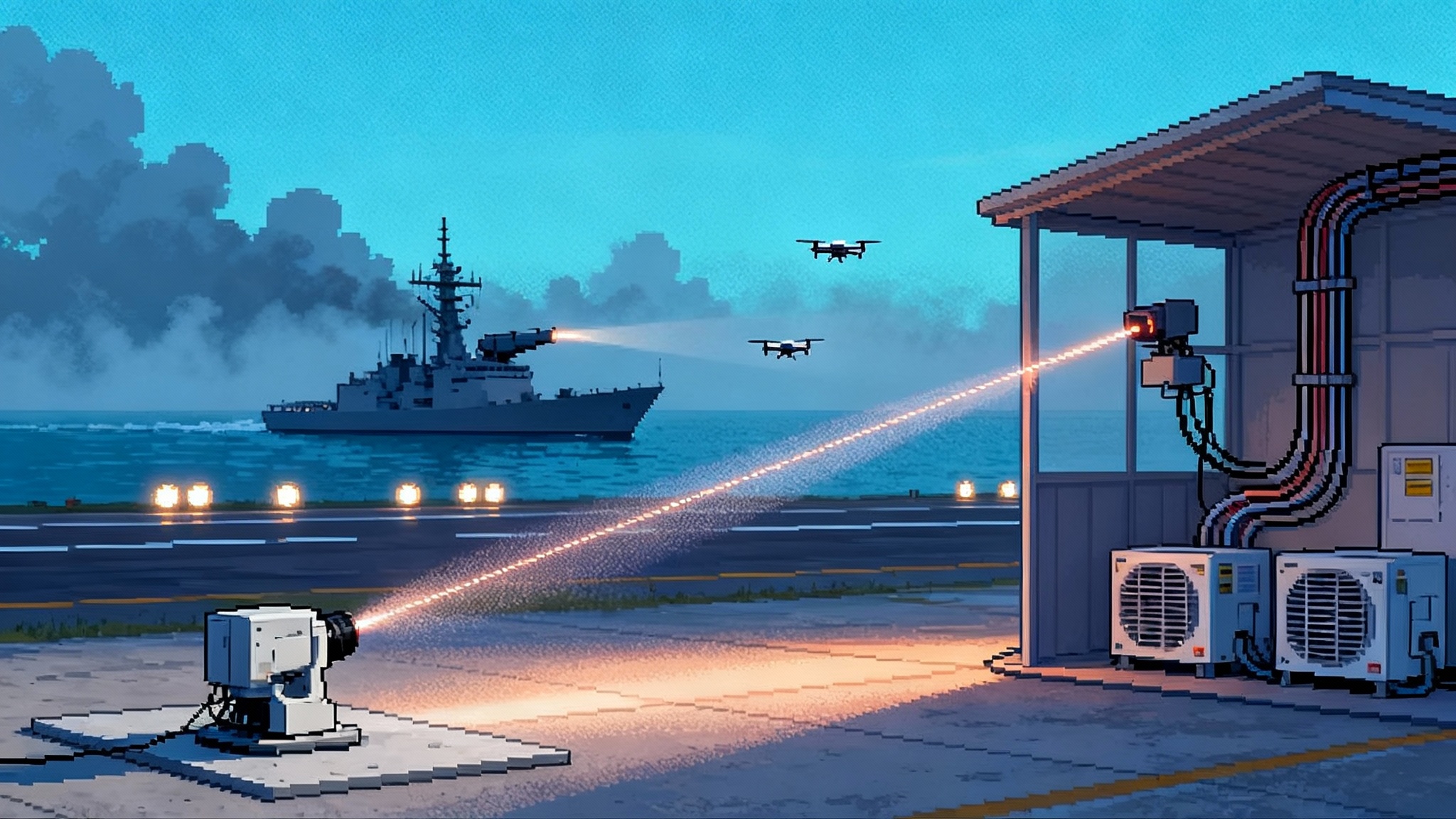

For the strategy context, see how lasers go operational in air defense once production and doctrine align, and how a hypersonic defense sprint 2026 to 2029 depends on similar industrial agility.

The real chokepoints that still cap surge capacity

Production lines only move as fast as their slowest inputs. In 2025 three bottlenecks matter most:

-

Energetics and propellants

A small set of U.S. government sites and a handful of contractors produce RDX, HMX, nitrocellulose and other energetics. Modernization is underway, but engineering, permits and construction timelines are measured in years, not months. -

Motors and seekers

Rocket motors remain a narrow-base specialty, and advanced seekers can throttle final assembly even when airframes and canisters are ready. Coordinated capacity planning across primes and tier suppliers is essential. -

Skilled labor

Robots do not run themselves. Cleared technicians, controls engineers and energetic-materials specialists are the rate-limiting step for third shifts and new bays.

What would unlock true surge capacity by 2026

- Lock in multi-year funding for consumables. Volume gains collapse when budgets oscillate. Multi-year buys and advance procurement give suppliers the confidence to hire, train and invest, as the Coyote counter-drone megadeal template illustrates for other mission areas.

- Treat energetics like critical infrastructure. Build redundant capacity for nitration, acids and key formulations, with inventory buffers sized for months, not weeks.

- Stand up a national rocket-motor initiative. Modular buildings, robotic flex cells and automated casting need long-term offtake agreements, supplier development grants and shared test schedules to sustain flow.

- Digitize the supply base, not just the primes. Require a shared digital thread from raw chemicals to final assembly so process drift is visible across companies within hours.

- Fix the workforce pipeline. Expand classified apprenticeships at government-owned, contractor-operated plants and stand up short academies for maintenance techs and controls engineers that feed directly into third shifts.

- Standardize where it counts. Open, reusable fixtures, test adapters and software interfaces cut changeover time and training hours.

The bottom line

This year’s ribbon cuttings and contracts mark a pivot from bespoke lines to software defined factories that can swing production like a seasoned kitchen in a dinner rush. If the United States follows through on energetics capacity, rocket-motor lines and the people who run them, 2026 can shift deterrence by volume rather than by promise.