Project Pele Goes Real: Mobile Reactors Enter Build

BWXT has started core manufacturing for the Defense Department’s Project Pele microreactor, moving the program from design reviews to real hardware. Here is what that shift means for microgrids, logistics, and edge compute over the next two years.

From paper to metal: the moment Project Pele became real

A quiet line in a summer press release signaled a big shift. BWX Technologies said it had begun the start of core manufacturing for the Defense Department’s Project Pele microreactor on July 24, 2025. That milestone moves the program out of slide decks and into the shop floor. Fuel pebbles and prismatic blocks stop being concept art. Welds, metrology, and quality assurance binders take their place.

Project Pele aims to deliver a transportable, high temperature gas‑cooled microreactor that produces between one and five megawatts of electricity. The reactor, its shielding, and its power conversion equipment are designed to fit into four standard twenty‑foot containers. The concept is simple to state and hard to execute: ship a small nuclear plant by truck, rail, or aircraft, then stand it up quickly wherever the mission demands resilient power.

That vision has hovered on the horizon for years. The factory work that began this summer makes near‑term outcomes concrete. BWXT reports that fuel fabrication for the prototype is complete and that Rolls Royce LibertyWorks is building the power conversion module. The program’s immediate calendar is practical rather than grand. Assemble, ship, integrate, test, and learn.

What changed with the build decision

Crossing into core manufacturing resets risk. Design reviews catch many problems, but materials reveal truths drawings do not. Real graphite blocks breathe. Real metallic alloys creep. Tolerances that looked easy at the workstation become day‑long setup jobs on the mill. When hardware work starts, schedules stop being aspirational. They are constrained by fixture availability, heat treatment cycles, and nondestructive examination queues.

For expeditionary power, this step matters because it shifts debate from whether a mobile reactor can be built to how well the first one performs. That changes how program managers plan, how base energy officers model their microgrids, and how logisticians think about the next contested campaign. It also seeds the vendor base with people who have touched the parts. That institutional muscle is what turns any first‑of‑a‑kind into a family.

A 1 to 5 MW plant in four boxes: what that can actually do

Military bases and forward sites live on a mix of diesel generators, batteries, and sometimes a tie to a fragile local grid. A reactor in the Pele class would act like a steady, always‑on heart that keeps the microgrid alive while batteries and gensets handle surges. The numbers are not abstract.

- One megawatt of steady power yields 24 megawatt‑hours per day. Diesel generators typically deliver about 14 kilowatt‑hours per gallon in the field once you account for real efficiency, partial loading, and losses. That means roughly 1,700 gallons of diesel per day to match one megawatt. Scale that to three megawatts and you are moving about 5,000 gallons per day. A microreactor turns those convoys into free capacity for ammunition, water, and medical supplies.

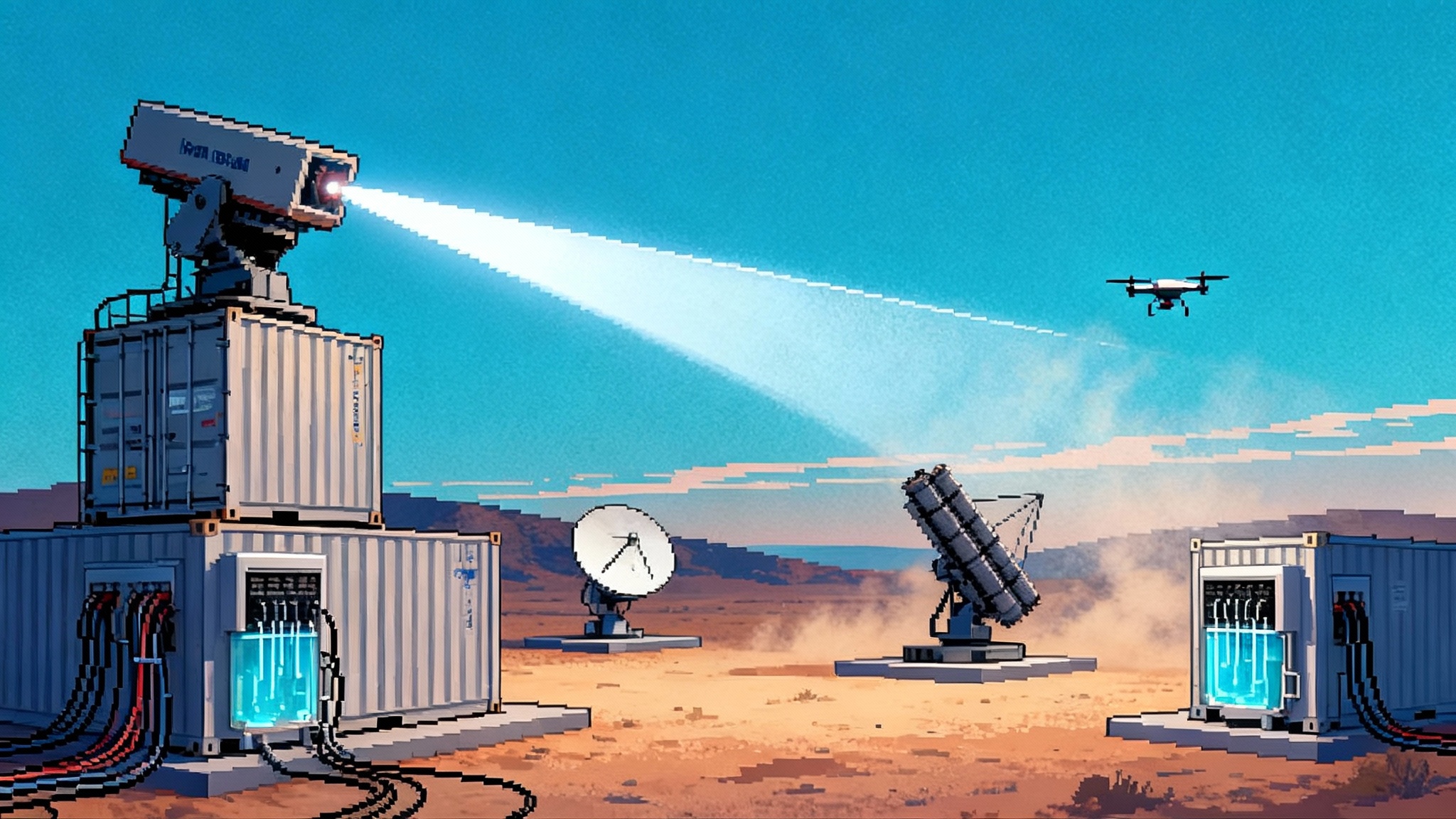

- Persistent sensors eat power. A modern rotating ground radar with counter‑drone modes can draw hundreds of kilowatts at high duty cycle. A cluster of such radars, electronic warfare receivers, and wide‑area radio frequency surveillance can easily live within a three to five megawatt budget with room for data links and environmental control. For context on counter‑drone demand signals, see how high power counter‑drone weapons are moving from trials to fielding.

- Edge computing is no longer a science project. A single forty‑foot compute container packed with graphics processing units can draw 200 to 400 kilowatts under sustained load. Two or three such containers support on‑site sensor fusion, autonomy training, and targeting algorithms without backhauling raw data over contested satellite links. This dovetails with recent autonomy advances like USAF uncrewed fighters flew.

These examples are not theoretical flourishes. They map to how commanders will actually use power at dispersed sites. A microreactor of this size does not replace everything. It becomes the anchor. Batteries absorb spikes. Existing diesel fleets handle unusual peaks or maintenance windows. The result is a microgrid that rides out fuel disruption with time to spare.

The next 24 months: from factory floor to integrated tests

The Department of Defense broke ground at Idaho National Laboratory’s test site in 2024 to prepare for the Pele prototype. The agency said the reactor would be shipped to the lab for assembly and integrated testing after site work and safety reviews DoD broke ground at INL. Since then, the manufacturing start in July 2025 reframed the immediate horizon. Here is what to watch between now and late 2027:

- Core and module fabrication at BWXT’s facilities moves from coupons and mockups to production parts. Expect discrete milestones like core block completion, reflector assembly fit checks, and pressure boundary certifications.

- Fuel and hardware shipments stage to Idaho National Laboratory. Early on, the lab exercises its logistics choreography. The reactor and the fuel travel separately. The site team rehearses receiving, inspection, and storage with the same muscle memory they will need for the real start‑up.

- Balance‑of‑plant work proceeds at the Critical Infrastructure Test Range Complex. This includes the concrete shield structure, the below‑grade conduit runs for medium‑voltage connections, and the switchgear that ties Pele into the lab’s microgrid.

- Cold fit checks align the reactor vessel, heat exchangers, and the Rolls Royce power conversion skid. This is where bolt patterns and gasket selections become schedule items.

- Integrated microgrid tests begin with dummy loads that mimic radars, satellite terminals, and compute racks. The aim is to validate protection settings, ride‑through behaviors, and islanding modes before the site moves into nuclear operations.

There is an important schedule nuance. In 2024, the department discussed an aggressive path to initial electricity as early as 2026 at the test range. In 2025, the manufacturer forecast power generation in 2028. Programs adjust as they touch real hardware. The near‑term story is still very active. Over the next two years, the action is in assembly, microgrid integration, and full‑up system tests that look and feel like the power problems operators actually have.

Resetting contested logistics

Campaign plans in the Indo Pacific and parts of Europe assume that fuel deliveries will be expensive, slow, and sometimes interdicted. Every gallon not moved reduces risk and frees up scarce sealift and tactical trucking. Microreactors change the math in three ways.

-

They convert convoy risk into installation risk that can be managed. Instead of many vehicles making frequent trips through chokepoints, logistics teams manage a small number of nuclear shipments with intense security and predictable routes. That is a different problem with a different risk profile. Security, deception, and scheduling work better when the number of high‑value movements is small.

-

They flatten the daily resupply curve. A base that needs thousands of gallons of diesel every day is chained to a cadence the adversary can exploit. A base with a microreactor and a modest stockpile of fuel for peaks can vary resupply timing. That complicates surveillance and targeting.

-

They unlock dispersion. Power‑hungry sites cluster because they need fuel. A reactor that arrives by aircraft or truck and sits quietly for years lets operational planners break up the target into smaller pieces without starving any one node of electricity. This pairs well with distributed electromagnetic effects like EA‑37B electronic warfare jammers.

Think of fuel logistics today like a river that must constantly flow or the lights go out. A microreactor creates a reservoir. The river still matters, but the base can ride out droughts and floods.

Powering sensors and edge compute the way they actually run

Most bases and forward sites are designed around peaks they rarely hit. Generators idle or run at poor efficiency, and batteries carry narrow slices of the day. A reactor shifts practice toward right‑sizing for reality. Here is how a Pele‑class unit could be used on the ground.

- Assign the reactor to the base load. Tie it to the medium‑voltage backbone of the microgrid and let it carry the constant draw of radars, communications, water treatment, and command posts.

- Use batteries as shock absorbers. Modern battery systems with smart inverters can handle very fast transients and keep frequency stable when a radar spins up or a compute rack jumps to full load. Batteries are also perfect for black starts and short maintenance windows.

- Keep diesel in the role it excels at. Diesel generators can provide extra headroom for flight operations or unusual surges. They are loud, dirty, and fuel limited, but they are fast and familiar.

For edge computing, it is helpful to run a thought experiment. Imagine an exercise at a desert test range. Three networked radars, two compute containers running sensor fusion and autonomy models, and a satellite ground terminal that moves data when it can. The reactor carries the steady draw. Batteries cover step changes when the radars run special waveforms or the compute nodes enter a high‑intensity training cycle. Diesel handles the odd case when the exercise director adds a surprise load. The team tests load‑shedding priorities and proves that mission software still runs when a generator trips offline. This is the kind of rehearsal commanders will want before they bet a real operation on a new power plant.

Safety, fuel, and oversight in plain terms

Project Pele uses TRISO fuel, which looks like tiny poppy seeds wrapped in high‑tech shells. Each particle contains uranium at the center, then multiple layers of ceramic and carbon that trap fission products even at very high temperatures. The reactor is helium cooled, which means there is no boiling water and no large steam loop to manage. The fuel and the core design aim to make it hard to overheat and easy to cool passively.

At the Idaho site, the Department of Energy provides safety oversight. The fuel and reactor components travel separately. The plan is to assemble the reactor at the test range, connect it to an isolated microgrid, and run it for several years at controlled power levels. The goal is not just to make electricity. It is to gather data on how a transportable plant behaves under the kind of start‑stop, move, and restart cycles a real mission would demand.

There is also a supply chain story inside this program. The United States needs a reliable source of high assay low enriched uranium to feed advanced reactors. BWXT and national laboratories have been producing the specialized TRISO fuel for Pele, which helps stand up people, processes, and quality systems. Even a single prototype builds a path for later units and for civilian microreactors that might share components and vendors.

What to do now: a playbook for two years of preparation

If you lead a base, a program office, or a vendor team, the right time to prepare is before the first kilowatt flows. A focused set of actions over the next 24 months will pay off.

- Build a digital twin of your base microgrid. Model your real loads at fifteen‑minute resolution. Include radars, satellite terminals, data centers, water plants, and flight operations. Run scenarios where your fuel deliveries stop for two weeks. Insert a steady one to three megawatt source and watch how batteries and diesels behave. Use those results to draft operating procedures with clear load‑shedding priorities.

- Pre‑stage the physical interfaces. Survey and set aside a pad that can accept four twenty‑foot containers, plus a shielded enclosure and service space. Standardize on medium‑voltage switchgear and connectors that match the Pele‑class output. The day you connect should feel like an installation, not a science fair.

- Train the microgrid operators you already have. The first crews who will run these systems are your best generator and battery technicians. Give them time at a lab or vendor facility to learn new normal operations, alarms, and shutdown steps. Build muscle memory for handoffs between reactor, batteries, and diesel.

- Rehearse security and emergency response. Write a short, practical plan for vehicle standoff, access control, and incident communications. Drill it with your local responders. The objective is speed and clarity, not ceremony.

- Plan how you will use the headroom. Do not buy a three megawatt plant and then run it at one megawatt forever. If a microreactor will anchor your grid, match it with new mission uses. Pre‑approve a list of compute workloads, sensors, and additive manufacturing gear that can spin up when you have reliable power.

These steps do not require a reactor on site. They require decisions you control.

How this resets the technology conversation

The first unit is a demonstration. It will live at a national lab and it will be heavily instrumented. That is by design. The difference now is that the questions get sharper. Instead of debating if a mobile reactor can exist, we will measure how it handles ramps, how it rides through faults, and how its real performance aligns with the models.

Even the limits will be useful. Suppose the thermal margins are tight in hot climates or the power conversion system dislikes sand and dust. Those findings inform whether later models need different cooling, filters, or auxiliary chillers. If set‑up takes longer than planned, the program can standardize better lifting fixtures, pre‑assembled cable looms, or different shielding geometries. Every lesson learned in Idaho is a lesson suppliers can build into the next container.

The bottom line

Project Pele has moved into the phase where metal meets schedule. Over the next 24 months, the most important work is boring to the outside world and decisive for the people who will depend on this power. Factory acceptance tests. Fit checks in Idaho. Microgrid drills that feel like real missions. The payoff is a future where a base commander can order a power plant by the container and get years of steady electricity without a daily fuel convoy. That is not a slogan. It is a logistical advantage you can count and a new way to plan operations.

The day the prototype makes first power will get the headlines. The deeper impact will come from the dozens of small decisions teams make between now and then. If they keep leaning into the unglamorous parts of building, testing, and integrating, the military will step into a world where electricity arrives as a kit, resilience is an input to planning, and contested logistics bend to a simpler rule: move less fuel, do more work.