Iron Beam Goes Operational: Lasers Reset Air Defense Math

Israel’s Iron Beam crossed a key September 2025 test milestone and is slated for service by year end, making lasers a real layer in air defense. Here is how cost per shot flips against drones and rockets, where high power microwaves fit, and what must scale by 2030.

The month lasers left the lab

In September 2025, Israel crossed a threshold many defense planners have discussed for decades. After multiweek trials in the south, the Ministry of Defense said Iron Beam had completed tests and would move into operational service before the end of 2025, the first high energy laser air defense to be fielded anywhere. That announcement confirmed what years of demonstrations implied: directed energy is ready to carry part of the air defense load, not as a science project but as a working system that can cue on a target and burn it out of the sky. Reuters: milestone and fielding plan.

The Hebrew name chosen for the deployed configuration, Or Eitan, honors a fallen commando and hints at the central idea. Light, harnessed at very high power and precisely aimed, can turn cheap enemy drones and rockets from a budget busting problem into a solvable equation.

The cost per shot flip, in plain numbers

Consider a common headache from Ukraine to the Middle East: a wave of small drones and short range rockets. Traditional interceptors are excellent, but they are finite and expensive. An interceptor might cost tens of thousands of dollars, and a determined attacker can launch dozens of cheap threats in a day. That mismatch erodes stockpiles and budgets.

Lasers reverse the curve. A high energy laser consumes mostly electricity. Each shot draws power, heats the beam director, and wears components over time, but the marginal cost per intercept is measured in single or low double digits of dollars rather than tens of thousands. Put differently, a defending battery can afford to fire all day without worrying that it is emptying a magazine of precision missiles. The practical limit becomes power and cooling, not purchase orders.

A concrete example helps. Imagine a small border town is probed by a set of ten low end drones in the afternoon, then pelted with mortar rounds at dusk. A traditional battery might expend 10 to 20 interceptors, burning through hundreds of thousands of dollars of inventory. With a laser, the operator slews, tracks, and holds the beam on each drone for a few seconds, with near zero consumables. Interceptors are preserved for the threats that most demand them, such as larger rockets, maneuvering cruise missiles, or bad weather shots where the laser is less effective.

There is an operational bonus too. A laser engages at the speed of light, so time of flight is effectively zero. That shrinks the window for an incoming drone to execute evasive maneuvers. In practice, time to kill is set by how long energy must dwell on the aimpoint to melt or ignite a critical component. For a small multirotor drone that can be seconds. For a dense rocket casing, it can be longer.

Layering lasers into existing defenses

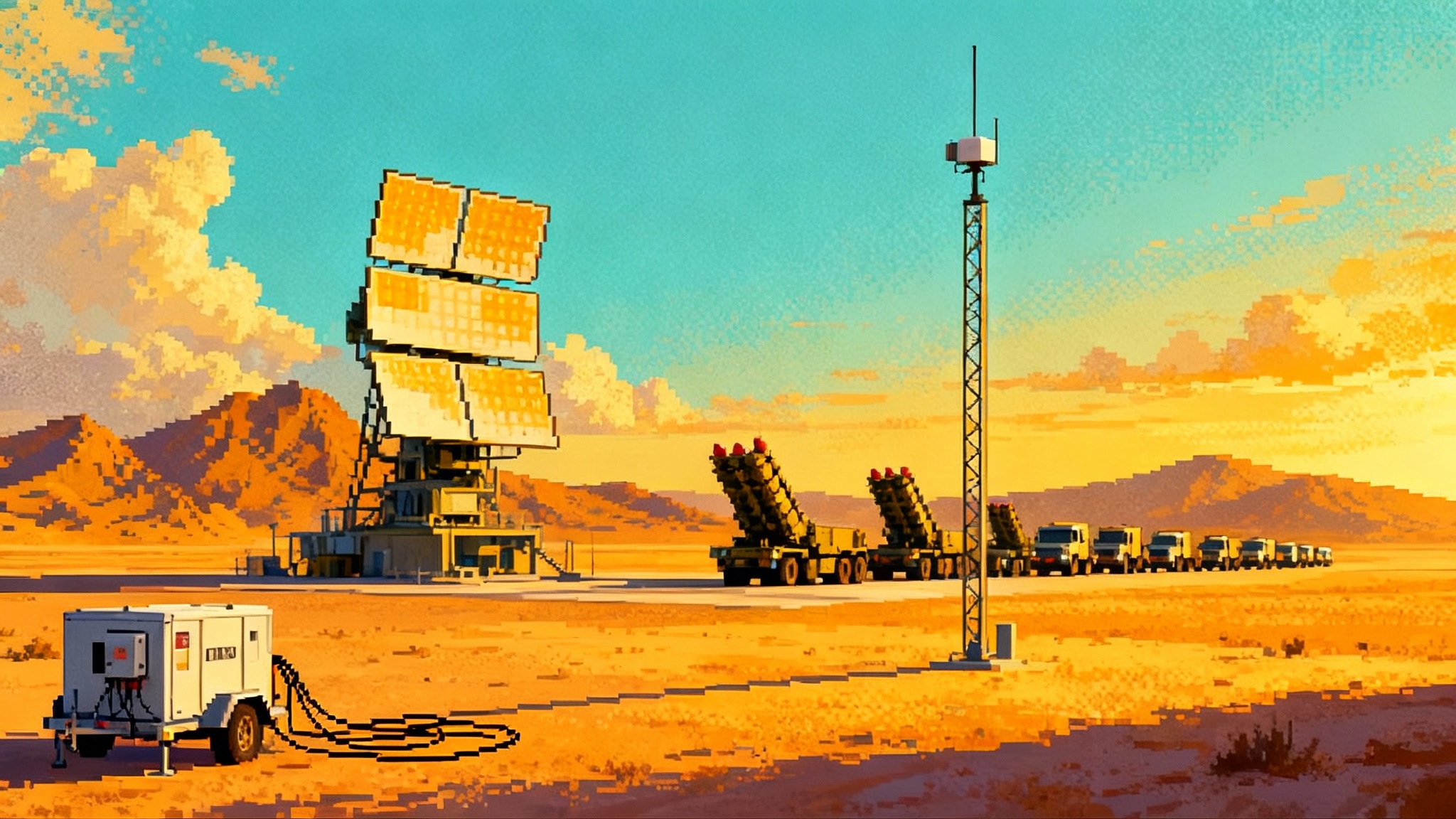

No commander wants a single point of failure. Israel’s approach treats Iron Beam as part of a layered stack that also includes Iron Dome, David’s Sling, and Arrow. Commanders match the effector to the threat. The laser handles small drones and short range rockets in clear air. Interceptors handle big or fast threats, shots at long range, and all bad weather work. Radars, electro optical sensors, and command software already used for kinetic systems help the laser find and track targets, so the new weapon slips into familiar workflows rather than creating an entirely new enterprise. See how this logic plays out in a joint kill web in Guam’s 2025 missile shield.

Allies are charting similar paths. The United Kingdom’s DragonFire program, led by MBDA with Leonardo and QinetiQ, accelerated after successful trials. The Ministry of Defence says the first shipboard installs will arrive in 2027, years ahead of the original schedule, a sign that procurement is shifting to spiral fielding and fast learning. That gives London a credible plan to put lasers inside its own layered air defenses rather than treating them as perpetual experiments. UK timeline confirms 2027 start.

In the United States, the Army has pushed 50 kilowatt class lasers onto Stryker vehicles as prototypes under Directed Energy Maneuver Short Range Air Defense. Those units have been exercised by air defense battalions and integrated with existing sensors so soldiers can practice cueing, deconfliction, and kill assessment. Meanwhile, the Navy and Air Force have been refining tactics for shipboard and fixed site directed energy. The point is not to replace missiles. It is to reserve those missiles for the hardest shots while lasers take the daily grind of small drones and mortars. For space based tracking that feeds the stack, see LEO and HBTSS tracking.

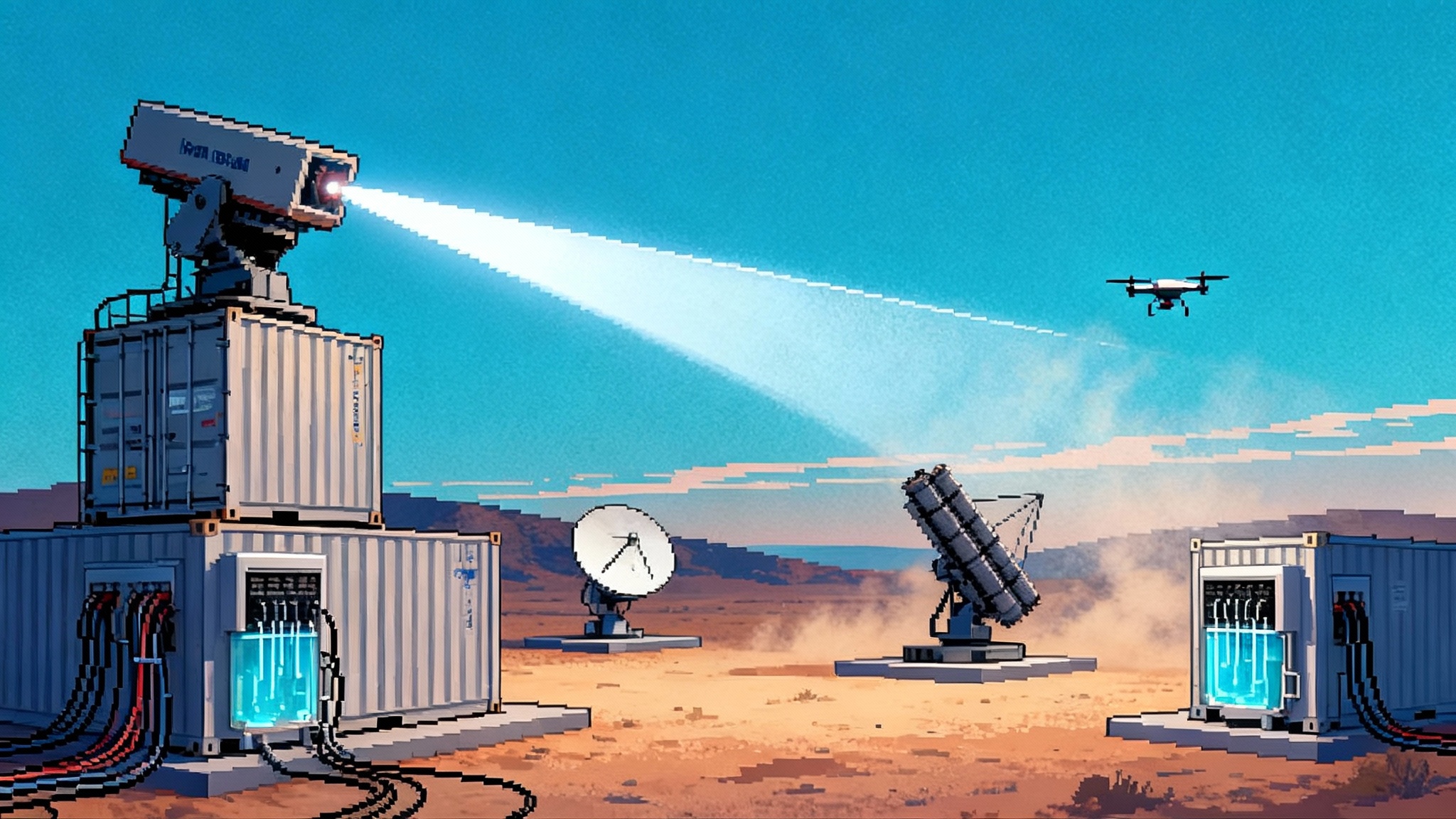

Where high power microwaves complement lasers

Lasers are precise scalpels. High power microwaves are area effects. They throw a cone of radio energy that can couple into drone electronics and stop them cold. Lasers shine against single drones or small numbers. High power microwaves shine against swarms. If a dozen quadcopters pop up from behind a ridge, a single microwave pulse can disable many at once. The tradeoffs are different. Lasers need steady aim and clear air. High power microwaves need careful deconfliction so friendly radios and electronics are not collateral damage. They also need precise rules of engagement to avoid violating spectrum restrictions in civilian areas.

A layered counter drone stack therefore looks like this. Lasers and high power microwaves cover the near fight. Short range missiles and proximity fused airburst rounds cover the mid fight. Long range interceptors and electronic warfare cover the far and fast fight. Cued by shared sensors and a common command screen, the operator picks the best tool for the target and the conditions.

The four near term hurdles to global scale

Fielding the first operational laser battery is a milestone. Scaling dozens of batteries across allies by 2030 is a different challenge. Four hurdles dominate that problem set.

- Power, thermal management, and duty cycle

A 100 kilowatt laser sounds like a light bulb number, but the real electrical load is larger once you include beam control, sensors, and cooling. The system pulls serious power in short bursts, then needs to shed heat to stay within the safe operating envelope. That creates two constraints for planners. First, power must be available in the right form at the battery site. That means containerized generators, battery storage buffers, or a connection to a stable microgrid. Second, the laser’s duty cycle limits how quickly it can engage successive targets in hot environments. Ships have an easier time because they can tap megawatts. Land batteries require smart power planning, including pre positioned fuels or hybrid renewable setups at fixed sites.

Action for 2026: when allies buy a laser battery, they should procure a matched power module and a thermal package as part of the system baseline, not as an afterthought. At bases, pair the laser with mobile microgrids and energy storage to smooth peak draws and reduce generator fuel burn.

- Weather and obscurants

Lasers love clear, dry air. Fog, rain, and dust scatter and absorb energy, which lengthens the time a beam must dwell on target and can push some shots out of reach. Smoke screens and battlefield dust are especially tough in complex terrain. Engineers fight back with adaptive optics that keep the beam tightly focused and with higher power or multiple beam architectures that can push more energy through the same air column. Operators fight back with tactics. They site lasers for up angle shots, where the line of sight is short, and they let missiles take the bad weather work.

Action for 2026: treat weather like terrain in training. Run live fire sequences in fog and rain and set clear rules on when to hand off to kinetic shooters. Capture local microclimate data at fixed sites to predict laser performance by hour and season.

- Command, control, and deconfliction

Lasers and high power microwaves do not help if they are trapped behind separate screens and radio nets. The big gains come when batteries plug into the same battle management that already drives interceptors and guns, so operators can see one picture and assign the right effector. That demands integration work at the software and tactics levels. It also demands rigorous deconfliction. A microwave shot can blind a friendly drone if the operator does not know it is in the cone. A laser can dazzle optics if a friendly sensor is on that line of sight.

Action for 2026: use the same command and control that runs interceptors as the nerve center for lasers and high power microwaves. Write procedures that force positive identification, line of sight checks, and no fire zones for optical sensors, and rehearse those checks in mixed live fire exercises.

- Industrial base and module supply

The quiet hero inside a modern laser weapon is a set of industrial fiber laser modules and the optical combiners that stitch them into a single beam. Those modules rely on specialty fibers, pump diodes, and precise optics. As orders rise, shortages can appear in surprising places, such as rare earth dopants for fiber or high power diode lines. Israel’s program leans on a partnership between a prime integrator and a dedicated laser source provider. Other allies are taking a similar approach, often with a local industrial partner and a global prime.

Action for 2026 to 2030: put laser modules, pump diodes, and combiners on multiyear contracts, not one off buys. Encourage dual use production lines that can flex between defense and industrial laser markets to smooth demand and keep prices down. Where export is likely, align export control frameworks early so components can move.

How fast can allies catch up

Speed will vary by mission and by where power is easiest to find.

-

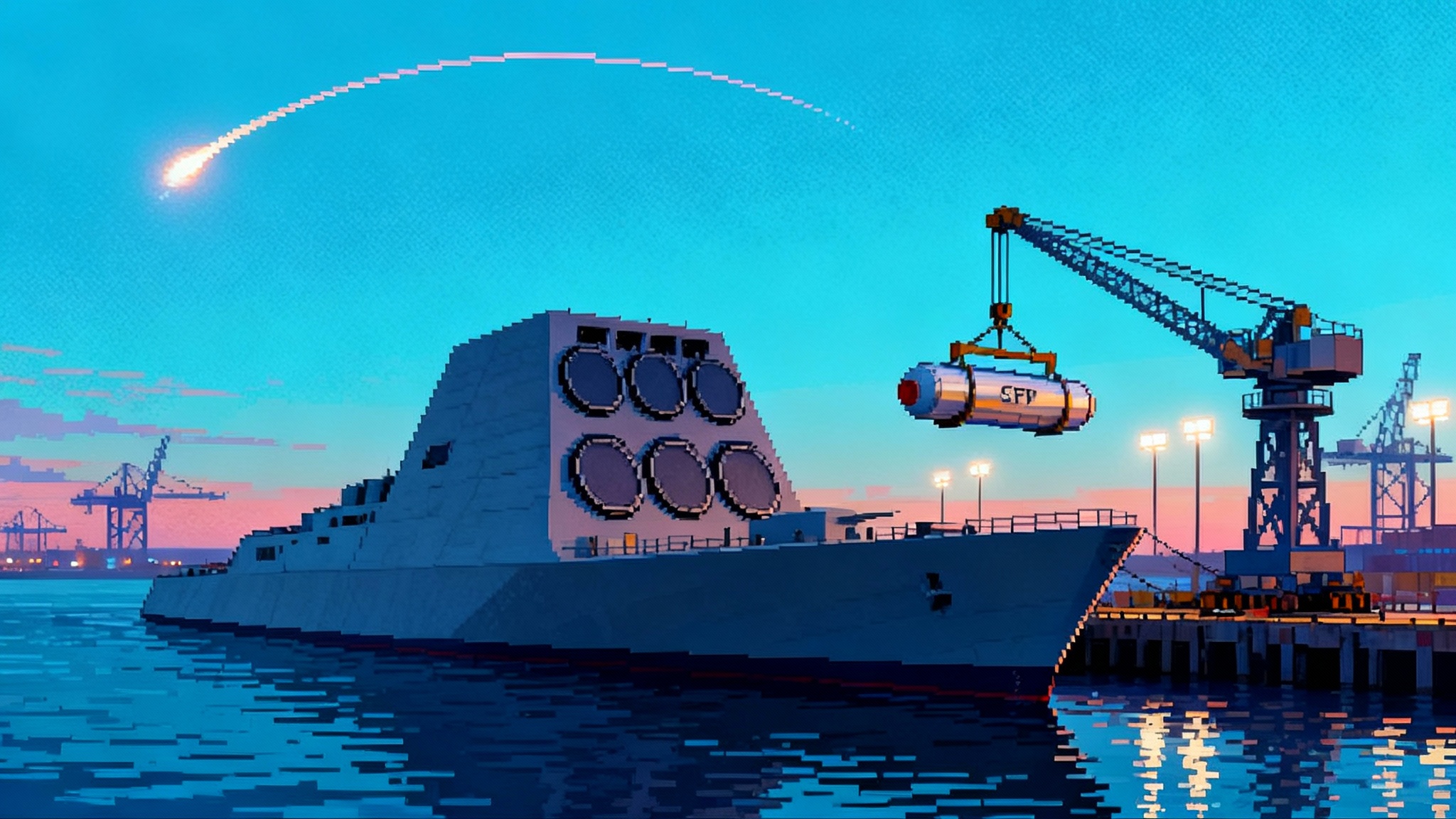

At sea, navies can move fastest. Warships generate megawatts and already have stabilized mounts, sensors, and battle management. Expect early operational laser mounts on destroyers and frigates to proliferate between 2027 and 2030, with missions focused on drones, small boats, and short range rockets. For related naval math shifts, see Japan’s shipboard railgun.

-

On land, fixed sites will lead. Air bases and critical infrastructure can host containerized power and cooling. Expect static laser batteries to sit alongside interceptors at select bases before the decade closes, with mobile trucked versions following as militaries gain confidence with power modules and crew training.

-

For maneuver brigades, the path is real but narrower. Vehicle power limits and the need to fire on the move put a premium on efficient beam directors and robust stabilization. Expect a mix of smaller lasers for drone defense and high power microwaves for swarm defeat, backed by kinetic interceptors when weather turns sour.

There is a diplomatic lane too. In 2022, Lockheed Martin and Rafael announced plans to co develop a variant of Iron Beam for the American market, which laid groundwork for future co production and commonality with United States forces. That sort of teaming can shorten integration cycles and make it easier to plug foreign laser batteries into allied sensor networks during coalition operations.

What it means for attackers

Drones and cheap rockets are not going away. Adversaries will adapt to lasers and high power microwaves. Expect reflective coatings, tumbling flight paths, decoy emitters, and more use of bad weather attack windows. Expect mixed salvos that try to soak up laser duty cycles before a heavier threat arrives. That means defenders will need both smart scheduling software and a healthy reserve of kinetic interceptors. The shooter that mixes a few dozen low end drones with one credible cruise missile is still a dangerous problem. Lasers shift the economics, but they do not erase the need for depth.

A playbook for 2026 to 2030

If you are an allied air defender, here is a concrete plan to get value from lasers fast without betting the farm.

-

Start with sites where power is easy. Pick a base or a port. Pair the laser with containerized power, a battery buffer, and a thermal module. Let the engineering team learn in a forgiving setting.

-

Integrate with your existing command software first. Do not build a parallel control room. Pull tracks from your current radars and electro optical sensors. Write and rehearse engagement procedures that assign lasers the first shot against drones in clear air.

-

Pair a laser with a high power microwave at one site. Use the laser for precision and the microwave for swarm defeat. Practice handoff and deconfliction, and have a standard no fire cone for friendly unmanned systems and optics.

-

Instrument the weather. Put real time atmospheric sensors near the battery and record performance in fog, dust, and rain. Feed those numbers into your shot priority logic so operators see a simple green, yellow, red indicator for laser effectiveness at any moment.

-

Lock in supply now. Place multiyear orders for laser modules, pump diodes, and optical combiners. Buy spare beam directors and window assemblies. Where possible, align specifications with partners so components can be swapped in a pinch.

-

Keep interceptors on the rails. The day you do not need missiles because you can shoot light all day has not arrived. Use lasers to preserve interceptors, not to replace them.

The bottom line

September 2025 will be remembered as the month lasers became part of day to day air defense. Iron Beam’s entry does not end the interceptor era. It rebalances it. By turning repeated small threats into electrical problems, lasers free commanders to save their expensive shots for the targets that deserve them. The next five years will be about scale, training, and smart integration. The allies that treat lasers and high power microwaves as tools inside a single battle network, not as standalone marvels, will get the most out of this moment.

And when the weather turns bad and the target is big, the old logic still applies. You will want interceptors, guns, and jammers ready. The new logic is that on most days, against most small threats, light will carry the weight.