Replicator’s Pivot: Cheap Autonomy Goes to Scale in 2025

The Pentagon’s Replicator program is crossing from pilots to production in 2025. Inside the buys, autonomy, and jam-resilient control that turn attritable air, sea, and ground drones into a scalable combat tool, plus what it means for the Indo-Pacific and industry.

The breakthrough is not a single drone. It is a new way to field many

If you only watch the high-end fighter conversation, it is easy to think the future of air warfare hinges on exquisite wingmen. Collaborative Combat Aircraft matters, but 2025’s real inflection point is quieter and wider. It is the Pentagon’s move to mass-field inexpensive, smart, expendable systems across air, sea, and land under Replicator. The signal this year is unmistakable: the center of gravity has shifted from demonstrations to production runs, from a few prototypes to many units the services can actually train with and employ. For a view of the higher-end path, see the FY26 uncrewed fighter race.

The Department of Defense set the tempo in 2023, promising to deliver multiple thousands of all-domain, attritable autonomous systems within 18 to 24 months. That goal anchored the first tranche of buys, publicly headlined by the AeroVironment Switchblade 600 loitering munition and a mix of uncrewed surface vessels and counter-drone tools, with the department framing these as pathfinders for scale. See the department’s own DoD first tranche selections.

In late 2024 and through 2025, the shopping list grew more concrete. Anduril’s Ghost-X and Performance Drone Works’ C-100 small uncrewed aircraft systems joined the roster, pairing surveillance and targeting with expeditionary logistics and modular payloads. Meanwhile, software and networking programs matured in parallel so that a swarm of unlike systems can behave like a team. The story of 2025 is therefore not a big reveal, but a stack of practical decisions that move attritable drones from interesting to inevitable.

From pilots to production: what changed this year

Three shifts defined this year’s Replicator activity.

-

More buys are production-ready. Rather than funding hopeful prototypes, the department concentrated on systems already in service or in low-rate production. Switchblade lines are hot, Ghost-X is already in formation with the Army’s company-level small uncrewed aircraft effort, and several small uncrewed surface vessels selected under the Navy’s production-ready push are being built by commercial shipyards that can add capacity fast.

-

Autonomy is moving to the edge. Edge autonomy means onboard software makes and executes decisions inside commander’s intent, even when links are degraded. Companies that productize autonomy stacks, such as Anduril with Ghost-X and L3Harris on collaborative teaming software, are optimizing for contested skies and seas. The practical effect is fewer operators per vehicle and more resilience under electronic attack.

-

The control layer is hardening. The Defense Innovation Unit ran two key efforts that matured in late 2024 and carried into 2025. Opportunistic, Resilient and Innovative Expeditionary Network Topology, often shortened to ORIENT, funds vendors like Viasat, Aalyria, Higher Ground, and IoT/AI to build mesh networks that hop across line-of-sight radios, cellular, and commercial satellite links to survive jamming. Autonomous Collaborative Teaming, or ACT, tasks firms including Anduril, L3Harris, and Swarm Aero to choreograph groups of vehicles across domains with a consistent user interface. The message is clear: the department is buying swarms, not just drones. Related space-layer resilience is arriving through the Tranche 1 LEO network.

Put simply, 2025 is the year the program behaves like a program. Hardware orders scale. Software schedules are real. Test events no longer look like tech demos; they look like workups for fleet tactics.

Autonomy at the edge, explained simply

Think of a patrol of scooters in a city delivering medicine during a blackout. Each scooter knows the street map, watches traffic, shares what it sees with nearby scooters, and chooses a route when the central dispatcher goes offline. That is autonomy at the edge. In military terms, the “scooters” are small aircraft, surface craft, or ground robots. Their onboard processors can classify targets, deconflict routes, and re-task within commander’s rules. They can also fall back to simple behaviors when sensors are blinded or links are jammed.

This is not abstract. Ghost-X’s software assigns search areas, keeps vehicles spread, and returns them to base when batteries run low. Small uncrewed surface craft can patrol set boxes and relay acoustic cues without constant operator input. Loitering munitions can orbit, receive a terse cue, and finish a strike without a full-motion video stream. The value is twofold: fewer people per mission and better performance when adversaries attack the network.

Jam-resistant command and control, the unsung workhorse

Electronic warfare is now table stakes in every theater. That drives two design imperatives. First, communications must be opportunistic and layered. If a high-bandwidth link is jammed, a vehicle should fail gracefully to a low-probability-of-intercept burst, or hop to a nearby vehicle acting as a relay. Second, the control stack must separate critical commands from nice-to-have telemetry. A four-word tasking that says “search this box” should get through even if the video feed drops.

The ORIENT effort exemplifies this. Vendors are fielding radios that can mesh at the edge, route around interference, and exploit commercial satellites without becoming dependent on any single constellation. The ACT effort is giving operators a common interface so mixed formations can be tasked as one. A small team can now deploy a basket of air and sea robots, task them like a pick-up soccer team, and keep them coherent despite adversary jamming. That is how you get scale without collapsing under the weight of human operators.

Why this matters most in the Indo-Pacific

The Indo-Pacific problem is geography. Distances are vast, bases are scarce, and adversary missiles can threaten obvious hubs. Replicator’s bet is that small, smart, and many beats big, few, and fragile in this environment. Uncrewed surface craft can sit forward for weeks as pickets. Small aircraft can surge from islands, ships, or trucks and saturate a target area. Ground robots can scout and guard key terrain with little logistics burden. This logic pairs with the region’s emerging kill web, highlighted in Guam’s 2025 joint kill web.

Here is the practical playbook that emerges:

- Pre-position attritable kits in sealed cases across the theater. A four-person team can unbox, test, and launch within an hour. This reduces lift demand on scarce cargo aircraft.

- Use mixed teams. A few medium-endurance aircraft cue many short-range quadcopters; a handful of surface craft cue loitering munitions. The big sensors stretch the formation, the small ones generate local density.

- Plan for high loss rates. Attritable means you can afford to lose some to enemy fire or the sea state. Logistics must stock batteries, propellers, and airframes the way units stock small arms parts.

The result for a potential Taiwan scenario is sobering for an adversary: a standing minefield of perception and strike, constantly replenished by small shipments and rapid local assembly, supported by autonomy that tolerates long stretches of silence.

Counter-drone at scale: Replicator’s second act

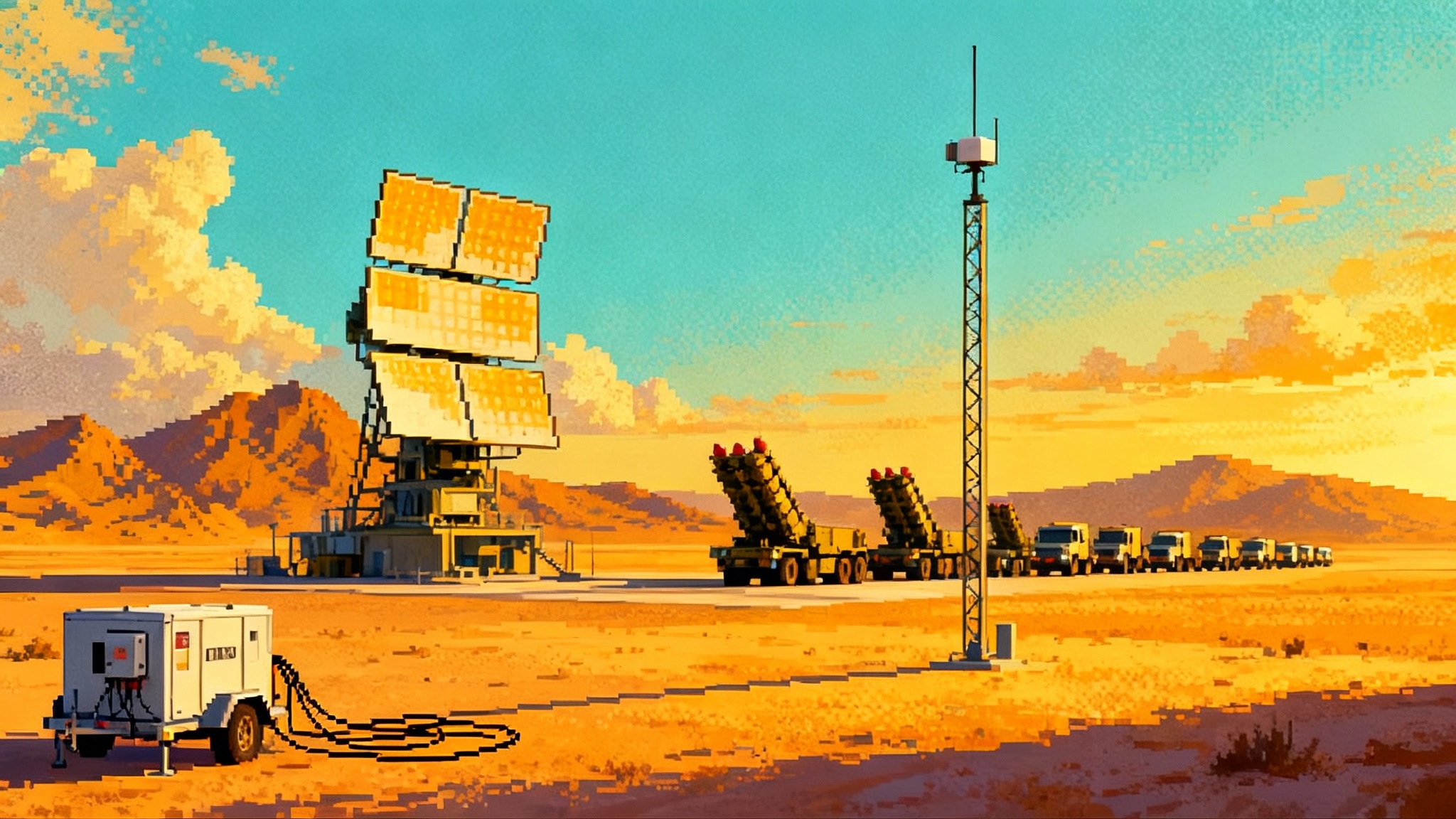

Replicator’s second iteration targets countering small uncrewed aerial systems at critical bases and force concentrations. The logic is simple. It makes little sense to buy thousands of friendly drones if static sites remain vulnerable to cheap quadcopters.

Expect a layered approach. Sensing will lean on passive radio frequency detection and short-range radar. Decision tools will use artificial intelligence to rate threats and recommend effectors. Defeat will be a menu: digital jamming, smart guns that lead targets, interceptors for overflight zones, and, in some cases, high-energy lasers for persistent defense where power is available. The hard part is integration. Base security forces need one picture, one set of rules, and effectors that do not create fratricide with friendly swarms. The payoff is high. A base that can cheaply swat down massed quadcopters reduces the enemy’s return on investment and preserves air operations under pressure.

What it means for the defense industrial base

Mass changes manufacturing. Vendors that long lived on boutique runs are retooling for tens of thousands of units. Three consequences are already visible.

- Factories are getting simpler and closer to operators. Drone lines fit inside standard industrial spaces near ports and rail. The right metric is units per worker per week, not years per ship.

- Software vendors are becoming prime contractors. When autonomy and networking determine mission value, integrators that own the software stack can coordinate hardware suppliers rather than the other way around. That is why firms like L3Harris and Anduril are building end-to-end autonomy ecosystems, and why traditional primes are investing in open architectures that accept third-party autonomy apps.

- Capital is noticing repeatable demand. Transition from prototypes to multi-year orders reduces risk for investors. Expect more private money to flow into component suppliers for batteries, electric motors, radio modules, gimbals, and composite airframes. The next chokepoints will be humble: magnets, bearings, and radio frequency chips.

For traditional shipyards and aircraft houses, the move to small, smart, many is not a threat to their existence but a reminder that volume and cycle time matter. The winners will be those who treat a small drone line with the rigor they give a fighter line, and those who volunteer to be the integration glue rather than guarding walled gardens.

The real risks as the model scales

Sustainment at tempo. Attritable does not mean disposable without plan. Units will burn through airframes, rotors, and battery packs in training and operations. The fix is to budget sustainment like ammunition, add local repair benches with spares and printers, and track mean time to repair with as much care as mean time between failure.

Jamming and deception. Adversaries will target both control links and perception. A formation that relies on perfect video will fail. Designs that prioritize terse command messages, onboard classification, and cross-checking among vehicles will ride out interference. Training must include blind runs, deceptive beacons, and red-on-blue electronic warfare so habits form before combat.

Export controls and the supply chain. Several key components have supply chains that run through jurisdictions with complex export regimes. If a critical radio frequency chip or magnet cannot be sourced domestically or from trusted partners, production will stall. The action here is to map the bill of materials, flag single-source risks, and set up dual-qualified suppliers. For allies, create license pathways early so coalition forces can buy, maintain, and operate the same kits without ad hoc waivers.

Unit training and doctrine. Swarms are not just more aircraft. They change tactics. Small teams will be able to shape a fight over wide areas. That requires updated rules of engagement, clear human-on-the-loop controls, and muscle memory for mixed formations. The fastest way to get there is to put production-representative systems in the hands of troops in large exercises and to institutionalize the lessons learned into schoolhouse syllabi within the year.

Public scrutiny and reliability. The bar for autonomy is rightly high. Failures will be news. The right answer is baked-in safety: positive target identification, geofencing, hard kill switches, and rigorous test plans that look like airline checklists, not lab notes.

Finally, timelines can slip. Reporting in late September indicated the initiative fell short of the August 2025 delivery goal in some areas, citing integration challenges and uneven reliability in field use; the long-term outcome still depends on how the services absorb and scale what did arrive. See Reuters’ summary of that report of shortfalls and delays.

Concrete implications and what to do next

For Indo-Pacific commanders

- Pre-position drone kits and spares at every hub that supports distributed operations. Treat them like rations and fuel, not like delicate gear that must be escorted.

- Train to electronic warfare first, bandwidth second. Write playbooks that assume intermittent connectivity and test them against a red team that jams and spoofs aggressively.

- Plan mixed formations by design. Pair a few longer-range scouts with many short-range attritable platforms and codify the handoffs.

For acquisition leaders

- Favor production lines that can double output in six months. Ask vendors to show takt time, first-pass yield, and supplier lead times. Reward those who reduce unit-hours per drone, not those who add boutique features.

- Contract for openness. Require interfaces that accept third-party autonomy and payloads without single-vendor certification bottlenecks. Make software bills of materials and interface control documents deliverables, not promises.

- Budget sustainment with teeth. Set spares ratios, battery replacement schedules, and repair kit inventories now. Measure readiness as a percentage of a swarm that can launch within two hours.

For industry

- Invest in component bottlenecks. Secure redundant sources for magnets, bearings, radio modules, and battery cells. The fastest growth limiter in 2026 will not be ideas; it will be parts.

- Productize autonomy. Move from bespoke algorithms to supported releases with cybersecurity hardening, test harnesses, and field support. The buyer is no longer a science project office; it is a battalion.

- Design for training abuse. Make airframes and boats that survive hard landings and rough seas, and document field-level repairs that take minutes with simple tools.

A closing view

The most important change Replicator brings in 2025 is cultural. It normalizes the idea that the United States can buy simple systems in large numbers, iterate them quickly, and knit them together with software to punch above their weight. There are bruises to show for it, including missed milestones and integration headaches. Those are the growing pains of a portfolio that is finally aimed at mass in a contested theater.

When historians look back, the hardware lists will matter less than the habits formed this year: autonomy pushed to the edge, control networks built to shrug off jamming, and a defense industrial base that learns to ship fast. That is how attritable drones stop being science projects and start being a standing part of deterrence in the Pacific. It is also how a military that is used to buying a few perfect things learns to fight with many good ones, and to win with them.