Defiant proves crewless warships are ready to scale

After a five-day open-ocean transit and an at-sea refueling demo in September 2025, DARPA’s NOMARS Defiant shows that uncrewed surface vessels are moving from experiments to deployable fleet tools. Here is how reliability, CONOPS, and costs change next.

Two September milestones that change the game

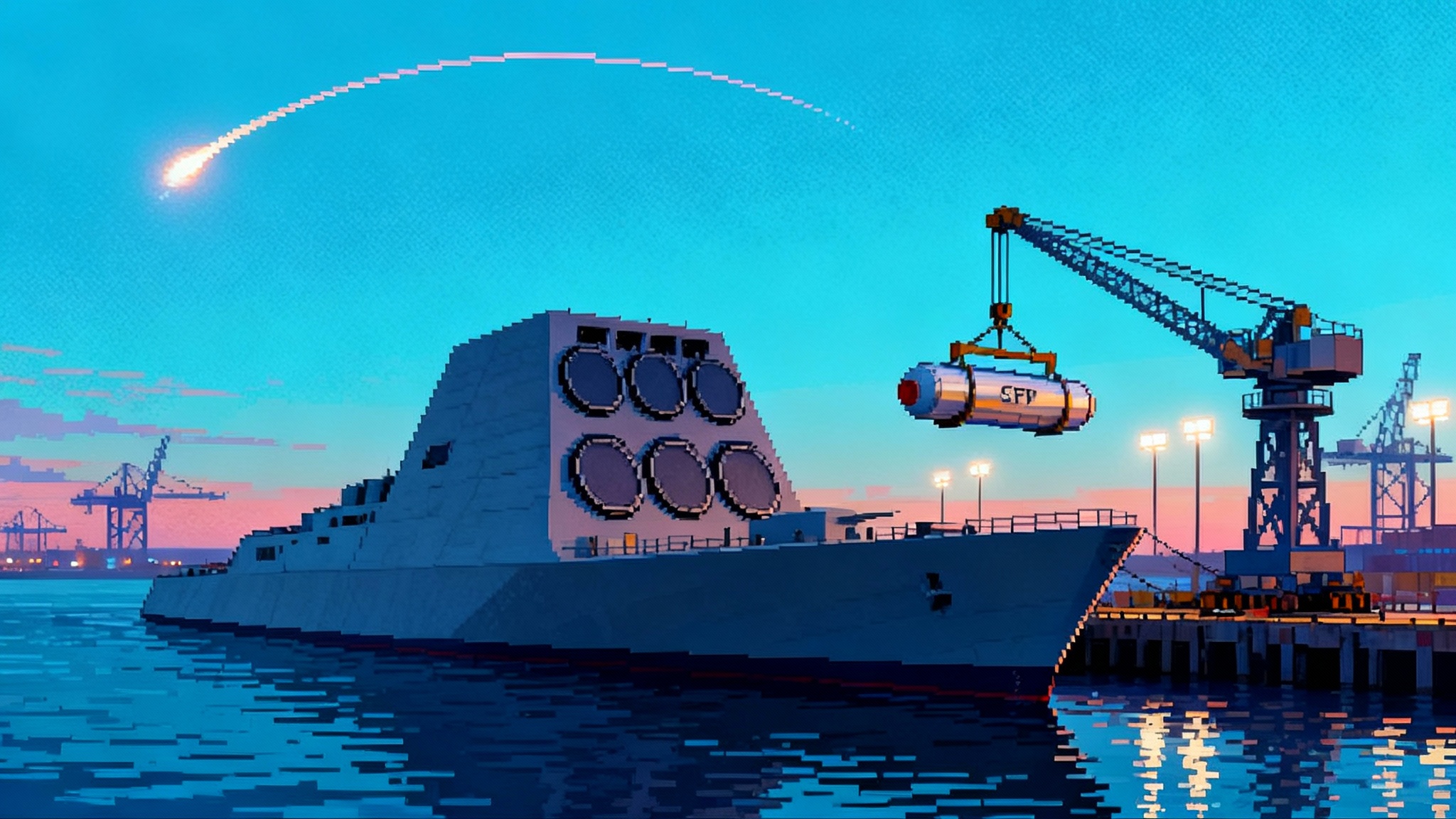

In the space of two September weeks, the Defense Advanced Research Projects Agency (DARPA) checked off the two hardest boxes on the path from demonstration to deployment for truly crewless warships. First, the agency’s No Manning Required Ship demonstrator, the 180‑foot USX‑1 Defiant, completed a five‑day, 1,100‑nautical‑mile open‑ocean transit from Port Angeles to Port Hueneme. Then, during trials off Naval Base Ventura County, the team executed an at‑sea refueling evolution with no one ever boarding the receiving vessel, pumping water in place of fuel to exercise the full procedure. Sailors from Unmanned Surface Vessel Squadron One participated, and the ship’s autonomy system also handled multiple dockings and high‑speed maneuvers near 20 knots. DARPA recorded both milestones in its at‑sea demo log in September 2025.

Why these events mark the crossover from demo to deployable

A single coastal sprint or a pier‑side hookup proves very little. An open‑ocean run proves seakeeping, navigation, and collision‑avoidance performance under real traffic, currents, and weather. A fueling‑at‑sea evolution proves the ship can join the Navy’s existing logistics backbone, which is run by Military Sealift Command oilers. Together, they validate the two pillars that have kept fully uncrewed surface vessels on the sidelines: endurance without pampering, and integration with fleet logistics.

Until now, “unmanned surface vessel” often meant a modified crewed hull with people standing by to intervene. Defiant is different. It was designed from the keel up to have no ladders, no passageways, no berthing, and no expectation that a human will ever step aboard at sea. That design choice forces novel reliability engineering, but it also unlocks new cost curves and new concepts of operations.

The radical implications of removing humans from the seaframe

Think of a traditional warship as a small city. Crews need food storage, fresh water, oxygen management, sewage treatment, lighting, fire‑safe passageways, ladders, air conditioning, medical spaces, workshops, and all the wiring, plumbing, and volume those imply. Remove the city and the hull can shrink to the minimum geometry that houses the mission equipment and the largest replaceable component. You immediately gain simpler lines, fewer penetrations in the hull, fewer human‑factor constraints on compartment shapes, and fewer systems that exist only to support people.

Defiant makes those tradeoffs explicit. The hull is a simplified, production‑friendly geometry, and the topside is a set of clean, accessible volumes for sensors, antennas, and mission payloads. The deck is a work surface rather than a workplace. By never hosting people at sea, the ship can accept different angles of roll and acceleration limits. It can be more densely packed because no one must squeeze through a tight gap at midnight in heavy seas.

There is a price. Without sailors to fix things underway, you must design for graceful degradation. Instead of damage control parties, you need graceful loss of function that does not spiral into mission kill. Instead of a machinist mate swapping a pump seal, you rely on redundancy, autonomous isolation, and remote diagnostics.

Reliability without relief: how to hit one‑year endurance targets

Engineering changes when no one is available to tighten a clamp or reboot a breaker.

- Availability becomes the key metric. If the seaframe must operate for a year without humans onboard, the prime movers, power conversion, cooling, and autonomy compute all need high mean time between failure at the system level, not just the component level. The solution is architectural: N+1 or N+2 redundancy for pumps and blowers, dual‑path power distribution, hot‑standby compute with checkpointing, and cross‑connected cooling loops.

- Condition‑based maintenance replaces scheduled maintenance. The ship needs a dense mesh of sensors reporting vibration, temperature, pressure, and insulation resistance back to shore. Analytics flag drift before it becomes failure, and the autonomy stack can reconfigure loads to buy time.

- Line‑replaceable units become the unit of action. Hardware is packaged as sealed modules with blind‑mate connectors and standardized footprints. Pier‑side technicians swap a module in minutes, then the failed one goes back to a depot for teardown. Mean time to repair at sea is irrelevant because repair never happens at sea.

- Seawater is the enemy, so the design treats it as inevitable. Cabling paths are double‑sealed with drip loops. Salt‑fog testing, conformal coatings on electronics, and sacrificial anodes are table stakes. The ship assumes leaks will occur and includes bilge segmentation with autonomous pumping and isolation.

A simple thought experiment motivates redundancy. Suppose a single essential pump has a five percent chance of failure per month. Over twelve months the probability of at least one failure exceeds forty percent. With two pumps in parallel and independent power feeds, the chance that both fail in the same month drops to one‑quarter of one percent, which keeps the ship on mission while the autonomy system sheds nonessential loads and reconfigures valves. Crewless ships are reliability math embodied in steel.

Autonomy is a ship system, not a magic trick

The autonomy you need for a year at sea is not a monolith. It is layers: navigation and collision avoidance to comply with the International Regulations for Preventing Collisions at Sea; health management that senses, diagnoses, and reconfigures systems; mission logic that decides when to hold position, sprint, or rendezvous; and safety monitors that can return the ship to a loiter box if conditions exceed limits. Defiant’s September port entries and exits under autonomy are as significant as the blue‑water miles, because harbors are where perception, path planning, and system health all collide under time pressure.

The at‑sea refueling evolution matters for autonomy too. The sequence is choreography: line passing, probe alignment, connection, verification, and pumping, all while maintaining station within tight tolerances. The trial off Port Hueneme used water, not fuel, to reduce hazard during the first full‑up sequence. The point was procedural validation. It showed that logistics crews on oilers can perform familiar tasks while the uncrewed ship handles the receiving side alone.

New concepts of operations for Distributed Maritime Operations

Distributed Maritime Operations is the Navy’s approach to complicating an adversary’s targeting by dispersing sensors, shooters, and decoys across a wide area, then networking them to mass effects on demand. That approach underpins the joint kill web across Guam.

- Picket and patrol: Crewless ships can sit on maritime chokepoints with passive sensors for weeks and then surge to a new station after refueling. Think of them as the fleet’s perimeter sensors that never need sleep.

- Extra magazine and remote launcher: A seaframe with standardized power, cooling, and data interfaces can accept containerized effectors, from long‑range decoys to anti‑ship missiles. The ship is an adapter plate for payloads.

- Deception and dilution: Even unarmed hulls have value as false targets. If an adversary must spend a missile on a $20 million hull, the trade favors the side that can afford to lose steel.

- Communications relay and gateway: Tall masts and persistent presence make crewless ships useful as network nodes, especially when satellites are jammed or clouds block airborne relays. This only strengthens as the LEO tracking layer going live improves resilient links and custody.

Concept of operations, often shortened to CONOPS, expands once you stop worrying about crew exposure. You can send a crewless ship into no‑notice storms if the mission demands it. You can accept riskier patrol patterns near hostile coasts. You can pre‑position hulls as loitering logistics caches that top off small crewed craft between replenishments.

Cost curves bend when people leave the platform

When you delete people from the design, you delete everything that exists to keep them alive and comfortable. That removes volume, mass, and complexity. Defiant’s clean hull and lack of human passageways are not aesthetic choices, they are production choices. Fewer parts, fewer custom compartments, and fewer safety‑of‑life systems mean fewer hours to build and fewer hours to maintain.

Just as important, the simplified seaframe opens the door to production at smaller Tier III shipyards that already build tugs, ferries, and workboats. That is exactly the domestic capacity you want if the goal is to scale to dozens or hundreds of hulls rather than a handful. A smaller yard can cut and weld a simple steel hull quickly, then integrate standardized modules and payloads shipped in by suppliers.

The learning curve compounds those savings. If early units cost X, a typical eighty‑five percent learning curve implies that by the tenth hull, labor hours drop to about forty percent of the first article. When the hull is simple and repeatable, the curve is steeper. The Navy has struggled to bend cost curves on exquisite, multi‑mission combatants with complex survivability features and dense habitability spaces. Crewless seaframes are the opposite. They are purpose‑built and edited down.

Transition is now a logistics and acquisition problem

The DARPA role is to break technical barriers, then hand the torch to the Navy for acquisition and integration. That hand‑off is already scripted. After the current at‑sea demonstration period, Defiant will transition to the Navy’s Unmanned Maritime Systems Program Office, known as PMS 406. Congress, in a July 2025 reconciliation bill, also set aside funding specifically for purpose‑built Medium Unmanned Surface Vessels. Those two facts make the pathway clear: finish trials, transfer stewardship, and move from a single demonstrator to a repeatable class with a minimum viable mission set. DARPA outlined the plan in its official christening release.

Here is a concrete, achievable sequence to get real mass in the water before this decade ends.

- Lock the baseline seaframe and autonomy core

- Freeze the hullform and interfaces that performed the September milestones. Do not re‑architect the ship in the name of perfect optimization. Establish a common autonomy core with defined upgrades on a six‑month cadence. Treat autonomy like a combat system, with configuration control, shore‑based test harnesses, and a fast patch pipeline. This approach aligns with the Replicator pivot to scale autonomy.

- Standardize payload, fueling, and docking interfaces

- Publish an open, vetted interface specification for power, cooling, data, and mechanical mounting. The goal is to let multiple vendors field mission packages that can be craned on and off in hours. Codify the receiving‑side fueling gear and the approach geometry so every Military Sealift Command crew can train to a single playbook.

- Build a three‑ship operational test detachment by mid‑2027

- One ship can prove endurance, two can prove rendezvous, and three can prove tactics. Use them to run scripted Distributed Maritime Operations events with destroyers, patrol craft, and maritime patrol aircraft. Write down the tactics that work, and stop arguing about the ones that do not.

- Stand up a depot and a data pipeline, not a tender

- The maintenance center is a shore facility with module spares, a calibration lab, and a teardown shop. Every pier‑side swap yields a digital record that feeds reliability models. The focus is predictive logistics, not underway repair.

- Buy in batches and contract for learning

- Issue a multi‑year procurement with options for blocks of five or ten hulls. Tie incentives to delivered availability and mean time to restore service at the pier, not just unit price. Make the shipyards publish their learning‑curve metrics with each block award.

- Train the fleet on the new normal

- Create a qualification course for oilers and harbor pilots working with crewless receivers. Train operations officers on how to task uncrewed pickets and how to write orders for autonomy rather than for line‑handling parties. Put Unmanned Surface Vessel Squadron One at the center of the curriculum.

What still needs proving before mass production

- Cyber hardening and electronic warfare resilience. Autonomous ships are computers on hulls. They need robust key management, out‑of‑band command links, and behavior that degrades safely under jamming rather than freezing or wandering.

- Collision rules and liability. Compliance with the International Regulations for Preventing Collisions at Sea is necessary but not sufficient. The Navy must also develop clear protocols for accident investigation and salvage when no crew is aboard.

- Weather tolerance beyond test windows. Sea state five is the nominal operating threshold. The fleet must understand how the ship behaves in the uglier tails, how often storms force loiter, and how quickly the ship recovers to mission speed.

- Payload integration tempo. The promise of a common seaframe fails if every new payload requires custom cabling and software tailoring. A strong interface standard and a small set of reference payloads are the antidote.

- Trust by commanders. Captains need a mental model for what the ship will do if a valve sticks or a sensor drops out. Frequent, instrumented fleet trials build that trust faster than thick manuals.

The cost of waiting is higher than the cost of learning

The United States is unlikely to out‑build every rival in large, crewed combatants. It can, however, out‑iterate on small, uncrewed hulls that are good enough to matter. The September 2025 milestones show that the core problems of endurance and replenishment are solvable on a clean‑sheet, no‑crew design. The Navy now faces an acquisition choice, not a science project. Moving from one ship to a dozen will surface integration snags, but that is how the reliability models get sharper, the interfaces get cleaner, and the price per hull drops.

The work is not glamorous. It looks like writing interface control documents, funding spare modules, and scheduling repetitive at‑sea trials. It looks like buying cranes, not fancy tenders. It looks like unnamed steel taking turns as pickets so that named ships can hide, rest, and strike on their own terms.

The bottom line

The line between experiment and fleet asset is crossed when a ship can sail, refuel, dock, and repeat, all without a person aboard. Defiant has crossed that line. If transition to Navy stewardship is rapid and disciplined, the service can put scalable, low‑cost mass in the water before the decade is out. That is how Distributed Maritime Operations stops being a briefing and starts being a fleet advantage: one quiet, crewless hull at a time.