Two B-21s, One Sprint: Dual-Ship Tests Rewrite Bomber Plans

A second B-21 Raider has joined flight test at Edwards AFB, unlocking parallel mission systems and weapons work while reducing production risk. Here’s how dual-ship trials quicken combat capability and sharpen Indo-Pacific strike concepts.

Two Raiders, one sprint

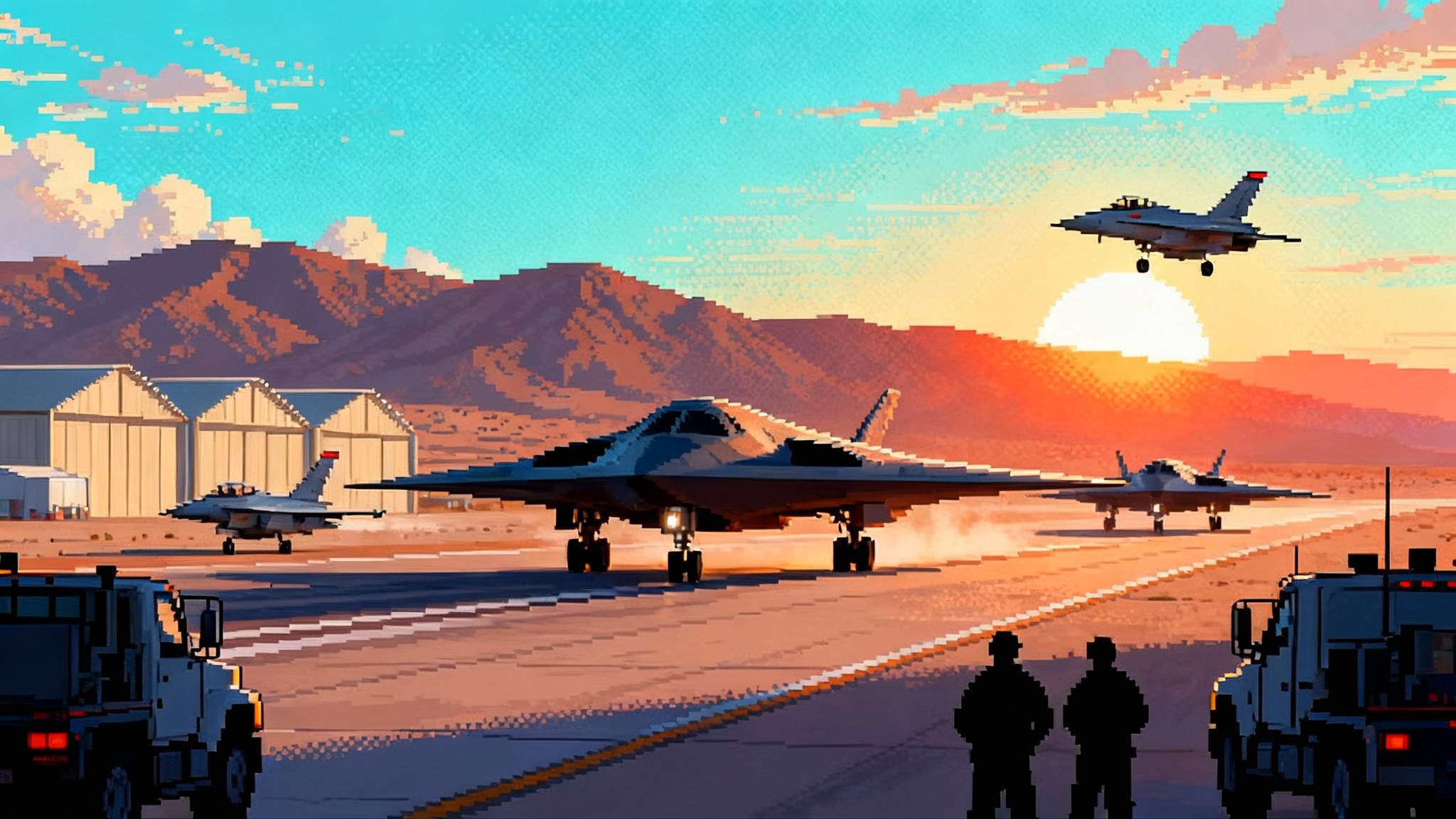

The B-21 Raider flight test campaign just shifted gears. On Sept. 11, 2025, a second B-21 arrived at Edwards Air Force Base following its first flight from Palmdale, joining the 420th Flight Test Squadron’s workups and expanding the program’s capacity to push beyond basic airworthiness into mission systems and weapons integration. The Air Force highlighted that the twin-jet setup enables a faster, deeper evaluation of the bomber’s combat hardware and software and gives maintainers real repetitions with real jets in a realistic tempo, not just in the lab or simulator. That is a meaningful inflection point for a program built to be software led and production minded from day one. Edwards AFB’s announcement captures the pivot.

Why a second airframe changes the test math

Flight test is constraint management. With a single aircraft, every hour must service three masters at once: flight sciences, mission systems, and maintainability. Two jets let the team decouple those streams and run in parallel.

- Parallelism across domains. One jet can carry the load on flight sciences workups and envelope expansion while the other focuses on radar, electronic warfare, communications, navigation, and weapons integration. That divide reduces context switching, which often burns scarce flight hours.

- Increased test point throughput. Two airframes allow more sorties, more configurations, and more regression checks in the same calendar time. When a software update lands, one jet can validate in a controlled configuration while the second pushes into new scenarios.

- Maintenance learning at scale. Sustainment concepts, tools, and low observable repair techniques mature faster when crews troubleshoot two real aircraft. That feedback flows directly into technical orders, training syllabi, and even design tweaks that improve reliability and turn times.

- Risk isolation. If one jet is down for instrumentation, modification, or anomaly resolution, the other keeps the campaign moving. That continuity matters when schedule is driven by capability increments as much as by airframe hours.

Mission systems and weapons integration at speed

More than any U.S. bomber before it, the B-21 is structured around open systems and a digital backbone. The Air Force describes the Raider as being designed with open systems architecture to reduce integration risk and enable competition for future upgrades as threats evolve. That approach is not just a buzzword. It underwrites a test philosophy that treats mission software as a living product and hardware as a stable host that can accept new payloads and effects with fewer bespoke integrations. See the Air Force fact sheet on open architecture.

With two jets in hand, the program can shift from proving basic functions to exercising the networking, sensing, and weapon employment threads that define modern strike, including how a proliferated LEO layer can tighten the kill web as shown in LEO mesh rewrites kill chains.

- Software trains, not monoliths. Instead of waiting for a large, infrequent drop that bundles many features, the program can field smaller, faster increments and validate them on one jet before promoting to the second. That creates a cadence that blends lab, hardware-in-the-loop, and flight evaluation without starving the schedule.

- Sensor fusion maturity. Fusion algorithms need diverse conditions to reveal edge cases. Flying two jets lets testers run synchronized scenarios with different loads or environmental variables, then compare results and fix issues earlier.

- Weapons separation and employment. Safe separation and guidance testing can be sequenced to use one airframe for captive carry and telemetry while the other handles environmental and performance checks. The fact that the aircraft is built to carry a mix of stand-off and direct attack munitions, in both conventional and nuclear roles, implies a broad test envelope that benefits from dual tails.

- Resilience drills. Mission systems are only as good as their behavior under stress. Two jets allow adversarial conditions to be recreated in a coordinated way, including contested communications, GPS degradation, and electronic attack, with one aircraft acting as a control in the same test window.

De-risking the production ramp

Getting to production is only half the battle; learning how to build predictably at rate is the rest. Dual-ship test operations feed the production system in four important ways:

-

Configuration discipline. When two flying articles absorb software and hardware changes, the team must lock configurations, label deltas, and prove repeatability. That discipline is the same muscle memory a factory needs to avoid expensive rework.

-

Digital thread validation. The B-21 program leans on digital engineering and model-based systems to connect design, manufacturing, and sustainment. Two active jets generate richer data that can reconcile models with reality. That lowers the risk that production assumptions were tuned to a one-off.

-

Supplier feedback loops. More sorties mean more parts consumed and more repairs performed. Early wear and unexpected failure modes surface quickly, giving suppliers time to adjust materials, tolerances, and processes before volumes rise. For a stealth bomber, this includes the chemistry and application processes of low observable materials, which are sensitive to climate, skill, and handling.

-

Factory-ops rehearsal. Maintenance metrics from flight test inform line-balancing in the factory, because the failure patterns seen on the ramp are often cousins of the build issues on the floor. If a component is hard to access in the hangar, it is often hard to install on the line. Fixing that now pays dividends later.

A different cadence than the last stealth bomber

The United States has built stealth bombers before, but the rulebook has changed. In the B-2 era, analog avionics and tightly coupled software made mission upgrades slow and expensive. Simulation was less mature, digital twins mostly aspirational, and data sharing across tools, teams, and primes was limited.

B-21’s concept emphasizes modularity and software agility from inception. That affects everything from how pylons, bays, and apertures are reserved for future payloads to how mission software is packaged, tested, and released. The aim is to turn bomber modernization into a series of smaller, reversible bets rather than a handful of risky, multi-year leaps.

Dual-ship testing amplifies that philosophy. One jet can run today’s stable load while the other trial runs the next increment. Compare that to legacy fleets that had to drag an entire squadron through a single update window, then accept months of regression risk.

Timelines that actually move

Bomber modernization timelines are usually a game of inertia. A second B-21 shifts that math. Here is what can realistically move left on the calendar:

- Initial fieldable mission loads. If the team can verify core mission threads with fewer backtracks, the first fieldable software load may arrive earlier relative to airframe hours. That shortens the gap between basic airworthiness and credible combat capability.

- Training pipeline milestones. Flightline maintainers, weapons troops, and avionics specialists learn faster when they can rotate between two aircraft with different maintenance states. That competence shows up in earlier qualification classes and a smoother transition to the formal training unit.

- Early operational assessments. Dual-aircraft test events enable more robust operationally representative evaluations, which in turn can give decision makers higher confidence to greenlight subsequent phases.

All of that said, stealth program history cautions against overpromising. Integration surprises are part of the journey. The benefit of two jets is not magic; it is momentum and resilience when the inevitable snags appear.

Indo-Pacific strike concepts get crisper

The Indo-Pacific theater forces long-range strike to confront range, survivability, and logistics at the same time. Two B-21s in test enable more credible answers to all three.

- Range and persistence. Testing can better map the true mission radius under realistic payloads and with operationally relevant profiles. That informs how many tankers are needed, where they should orbit, and which refueling windows are least vulnerable.

- Penetration tactics against modern defenses. Live runs with two jets allow cooperative behaviors to be explored, such as timing and routing deconfliction, sensor sharing, and silent handoffs that limit exposure to integrated air defense systems. These patterns parallel what the Air Force is learning with CCA drone wingmen first flights.

- Distributed operations. Agile Combat Employment depends on turn times, ground support footprints, and the reliability of low observable restoration after austere operations. With two aircraft, testers can vary base conditions in tighter cycles and measure real effects on tempo.

- Kill chain elasticity. Indo-Pacific operations rely on resilient command and control with graceful degradation. Dual-ship trials create opportunities to evaluate mission performance when data links are intermittent or when aircraft must switch from networked to autonomous modes mid-sortie, complementing land-based fires such as Typhon land-based Tomahawk deterrence.

The result is not just a better-tested aircraft, but sharper concepts of employment. Those concepts will influence how the Air Force sequences the handoff between legacy bombers and the Raider and how joint planners assign roles across long-range shooters, from bombers to submarines to land-based fires.

Industrial base implications

A two-jet test campaign pushes more stress into the supply chain, but that is a feature, not a bug. The earlier the network of suppliers sees real demand signals, the earlier it can scale.

- Materials and processes. Stealth coatings, composite layups, and precision structures demand consistent process control. Dual-ship testing accelerates the cycle of defect detection, root cause analysis, and corrective action plans. That lowers the probability of quality shocks during a production ramp.

- Talent pipelines. Skilled labor for low observable application, composites, avionics integration, and precision assembly is scarce. Two jets flying at once justify larger classes of apprentices and cross-training courses, which stabilizes throughput.

- Second sources and competition. Open systems principles invite more competition for mission systems upgrades over time. That prospect encourages broader participation and investment across the industrial base instead of locking the program into a narrow vendor set. The Air Force has identified a set of major partners on the program, including Pratt and Whitney, Collins Aerospace, GKN Aerospace, BAE Systems, Spirit AeroSystems, and Janicki Industries. The presence of multiple test articles will generate data that helps government and industry decide where to add capacity and where to prune risk.

- Sustainment as design input. Real maintenance data from two jets feeds back into depot planning and the digital product baseline. For a long-lived bomber, that can save billions by making early design changes that reduce life cycle touch labor.

How dual-ship trials compare to past stealth programs

Past stealth programs often experienced a fork in the road between test and production. Concurrency was high, but the digital plumbing to make concurrency safe was not. The Raider’s digital-first approach and open architecture provide better scaffolding.

- Faster software cycles. The gates between lab, rig, and flight are designed to be shorter and better instrumented. Two aircraft let the team keep one on the latest stable load while the other bears the risk of the next build.

- Cleaner hardware baselines. The program’s emphasis on designing for production helps fix hardware early and shift variability into software where it is cheaper to iterate. That reduces the odds of fleetwide retrofit campaigns later.

- Better sustainment handoff. Two jets enable earlier validation of technical data, manuals, and diagnostics. That means the field does not inherit guesswork.

None of this guarantees a smooth ride. But it raises the floor and lowers the ceiling on bad outcomes, which is the essence of de-risking.

What to watch next

As the second B-21 settles into the rhythm of test, a few indicators will tell you whether the acceleration is real:

- Sortie cadence and mission mix. Are we seeing a shift from envelope work to mission threads, and are both jets flying routinely without long downtimes for instrumentation swaps?

- Software increment tempo. Do software releases arrive in smaller packages on a predictable beat, with rapid regression and promotion cycles between aircraft?

- Early weapons events. Captive carry, safe separation, and guidance evaluations are pivotal. Evidence of stepped progress here would validate the dual-ship logic.

- Maintenance metrics. Watch for signs of faster turn times, fewer repeat discrepancies, and improved low observable restoration after heavy sortie days.

- Training milestones. The sooner maintainers, aircrew, and weapons troops are achieving qualifications tied to realistic tasks, the healthier the transition will be when the formal training unit scales up.

- Transparency on risks. Mature programs communicate issues early and show their burn-down plans. Expect to hear about problems, not silence.

Bottom line

Adding a second B-21 to flight test is far more than a photo op. It is the mechanical advantage the program needs to move from proving it can fly to proving it can fight, sustain, and scale. Two jets unlock parallel mission systems work, accelerate weapons integration, and surface production and sustainment issues when they are still cheap to fix. That momentum will shape how fast the Air Force can shift from legacy bombers to a software-driven fleet designed to evolve in stride with the threat. In the Indo-Pacific, where range, survivability, and logistics all fight for priority, that pace is not a luxury. It is the strategy.