America’s LNG Reset: CP2’s Greenlight and the 2026 to 2030 Push

With CP2 approved in late October, U.S. LNG is shifting from permits to execution. Here is what is truly shovel ready, what could reach final investment decision, where bottlenecks will bite, and how buyers are contracting for the next wave.

The reset moment

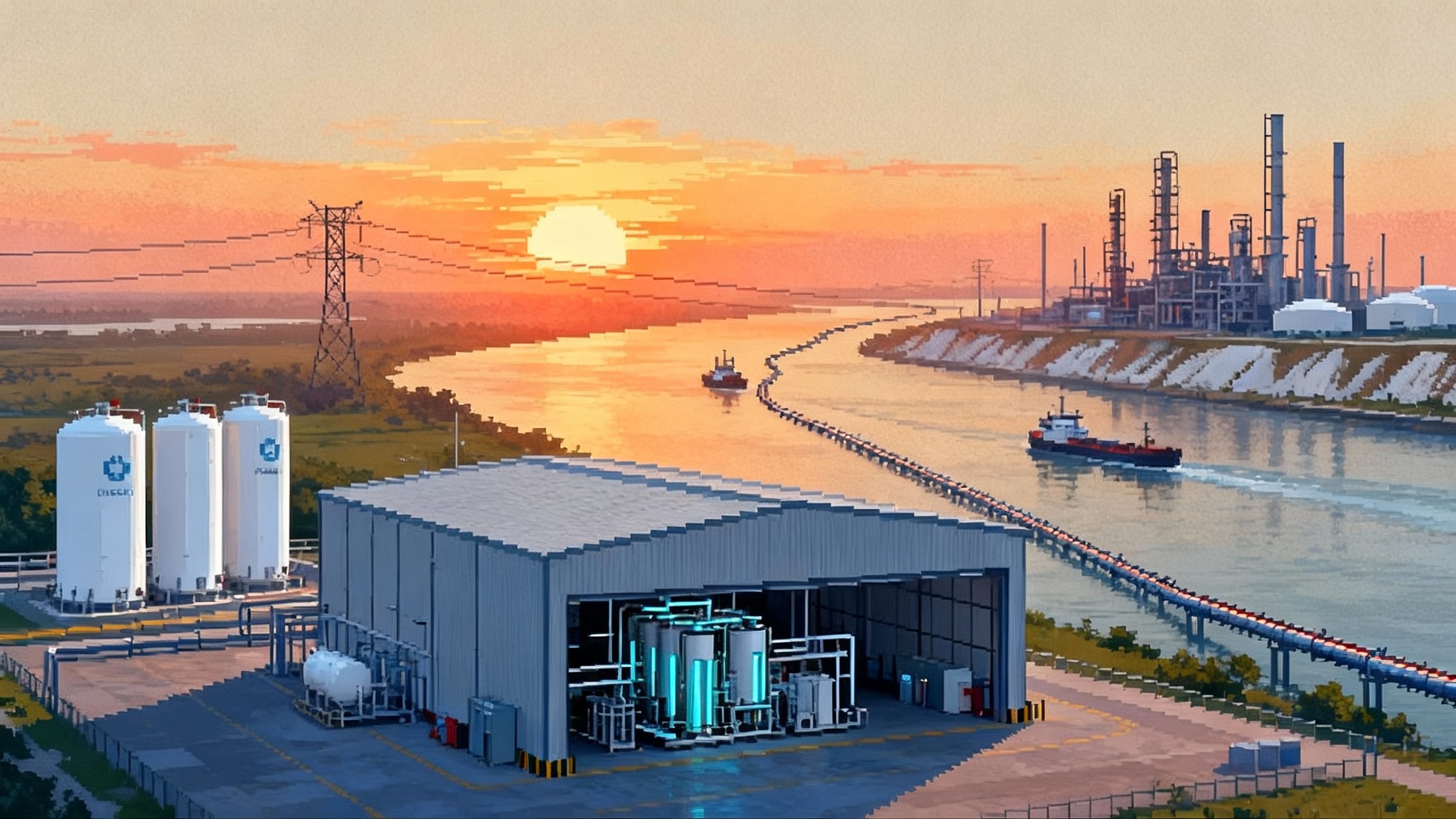

On October 21, 2025 the Department of Energy issued the final non free trade export authorization for Venture Global’s CP2 in Cameron Parish, Louisiana. That order removed the last federal barrier to full market access for one of the largest U.S. liquefaction projects now in construction, and it became the signal event in a broader reacceleration of permits after a year of fits and starts. The decision is not a headline in isolation. It is the hinge upon which a 2026 to 2030 buildout now swings, from trains and tanks to pipe and ships. The scale is large enough that a single weak link can delay first gas by quarters, not weeks. For those planning capital or supply strategies, the question is no longer whether the window has opened. It is how fast you can move through it without tripping on new methane rules or courtroom steps. For the record and for high stakes clarity, the CP2 approval is documented in DOE’s final authorization for CP2.

Who is truly shovel ready

Think of the Gulf Coast as a relay. Some runners have the baton and are already in stride. Others are bouncing on their toes at the line. A few are still lacing shoes.

-

Venture Global CP2, Louisiana. Construction is advancing on site works and long lead components, with the final DOE export order in hand. The design pairs a 20 million tonnes per year nameplate with optimized operation around 28 million tonnes per year under favorable conditions. Venture Global’s modular philosophy will again rely on factory built liquefaction blocks and large power islands. After the Calcasieu Pass commissioning saga, the execution focus will be a disciplined turnover plan from power systems through cold boxes to marine.

-

Golden Pass, Texas. This ExxonMobil and QatarEnergy joint venture has slogged through contractor upheaval and still pushed toward commissioning milestones. Expect first cargoes to slip into 2026 if weather or remaining contractor transitions take time, with the balance of trains phasing in through 2026 and into 2027. The lessons are stark for every new sponsor. Lump sum risk on mega packages, workforce swings and specialty subcontractors can bend timetables even when the owners are deep pocketed and determined.

-

Sempra Port Arthur Phase 1, Texas. Train 1 targets 2027 and Train 2 targets 2028 with Bechtel as engineering, procurement and construction contractor. The ground game is well underway, and the learning curve from Phase 1 now directly feeds Phase 2.

-

Sempra Port Arthur Phase 2, Texas. This expansion cleared the key export authorization and signed fresh offtake. With Phase 1 crews mobilized, Phase 2 is positioned for a faster ramp once the financing and partner stack is final. Expect first operation dates beginning around 2030 if notice to proceed remains on the near term calendar.

-

NextDecade Rio Grande Phase 1, Texas. Three trains are in construction in Brownsville with Bechtel. Train 4 reached positive investment decision in September 2025 and is now in the work queue. The site has two storage tanks and two jetties planned for Phase 1. The paired pipeline, Rio Bravo, is designed to move roughly 4.5 billion cubic feet per day from Agua Dulce to the terminal, matching the appetite of a full five train complex.

-

Cheniere Corpus Christi Stage 3 and Midscale 8 and 9, Texas. Trains from the Stage 3 midscale program reached substantial completion in 2025, and Cheniere gave full notice to proceed on Midscale 8 and 9 in June. The company’s brownfield playbook is simple. Keep Bechtel on the pads, standardize modules and raise output in bite sized steps that lenders and insurers understand. Tax neutral incentives are reshaping project finance, as outlined in tech neutral credits upend finance.

-

Commonwealth LNG, Louisiana. The project secured its non free trade export authorization in late summer and has been methodically filling its commercial book with long term offtake, including Asian buyers. A recent state level permit challenge illustrates a reality of the next wave. Dockets and deadlines will ride alongside welding schedules. Sponsors need legal calendars that are as detailed as their construction schedules.

-

Texas LNG, Brownsville. FERC reissued its final order and approved a construction schedule in late August 2025, bringing the project back onto a definable path. A year end final investment decision target and a 2029 completion schedule are ambitious but realistic if site works and long lead items are locked by mid 2026.

-

Lake Charles LNG, Louisiana. Energy Transfer spent the year reassembling its commercial and equity stack. The project carries permits and a marketing roster that would have closed financing in a looser labor market. Today it still needs firmed equity commitments and a crisp execution plan to be considered shovel ready.

Across these projects a pattern emerges. Brownfield expansions with active EPC crews are racing ahead. First time greenfield sites must solve three puzzles at once. They must lock a contractor willing to share risk, secure tank and module slots before they vanish and ensure their pipeline tie ins are commissioned before turbines spin.

Pipelines and feedgas: the unseen critical path

Liquefaction is only as good as the gas that reaches it. The next wave leans on several feedgas corridors:

-

Haynesville to Louisiana coast. Williams’ Louisiana Energy Gateway has begun service and is ramping toward full capacity in 2026, easing the high utilization corridor that delivers to Plaquemines, Sabine Pass and Cameron Parish. Kinder Morgan’s Evangeline Pass expansion steps in as a targeted Plaquemines supply booster, with Phase 1 in service and Phase 2 on track.

-

Agua Dulce to Brownsville. The Rio Bravo Pipeline is purpose built to feed Rio Grande LNG at up to 4.5 billion cubic feet per day via two large diameter lines from the South Texas hub. Enbridge’s joint venture structure spreads capital and puts a competent owner on the steel.

-

East Texas and Southwest Louisiana into CP2. The CP Express project pairs approximately 85 miles of 48 inch line, a major compressor station and multiple interconnects to deliver about 4 billion cubic feet per day to CP2’s terminal. The order of operations matters. Pipeline in service dates must lead liquefaction cooldown by months, not days, to allow pressure and quality tuning before first ship.

-

Permian relief. Matterhorn added a safety valve in 2024 and continues to ramp. Whistler and Permian Highway expansions, along with additional gathering and treating, will balance the associated gas waves from oil growth. The implication for liquefaction owners is simple. If you can pull from both Permian and Haynesville, your supply plan can handle basin specific weather and price whipsaws.

As a rule of thumb, a 15 million tonne per year terminal needs roughly 2.1 to 2.3 billion cubic feet per day of firm, metered, and schedulable supply. Contracts that rely on interruptible haul during peak winter burn or shoulder season pigging will show up as boil off and suboptimal train turndown. Secure the firm transport first. It is cheaper than a year of slip.

EPC, tanks and modules: where bottlenecks bite

Limited EPC capacity is now a structural feature, not a transient headache. A small club of contractors can credibly wrap a multi train Gulf Coast project at scale. Their rosters are already spread across Port Arthur, Corpus Christi, Brownsville and points east. The consequences are visible on job sites and in bids:

-

Labor market. Welders, pipefitters, electricians and instrument techs can command higher wages and per diems. Moving crews between overlapping mega jobs drags productivity. Sponsors that insist on fully lump sum turnkey terms often discover that the risk premium they pay ends up larger than a hybrid pricing model with transparent escalation and shared contingencies. Power procurement is tightening as the AI driven power demand shift reworks utility plans.

-

Tanks. Full containment storage tanks rely on 9 percent nickel steel plate, cryogenic inner tanks and a handful of fabricators with deep experience. CB&I within McDermott remains a dominant player. Scheduling a pair of 180 thousand to 200 thousand cubic meter tanks in the 2026 to 2029 window requires commitments now. Tanks are not the place to experiment with newcomers.

-

Modules and rotating equipment. Cold boxes, refrigerant compressors and power island components are booked months ahead. The group of qualified manufacturers is tight. Baker Hughes and a few peers have long lead queues. Owners that try to swap vendors late in the game pay twice. First in liquidated damages, then in lost integration time.

-

Weather hardening. Hurricane and flood resilience is no longer optional. Elevations, levees around development areas, enclosed ground flares and storm resistant electrical rooms should be treated as schedule critical path items. Rebuilding after one storm is more expensive than adding a month to lift elevations.

The practical takeaway. Secure EPC alignment on labor and subcontractor plans early, procure tank and module slots before you sign the last sales and purchase agreement and build a commissioning schedule that assumes at least one major weather interruption.

Berths and boats: marine constraints you cannot wave away

The two jetties that look ample on a site map can become chokepoints when train start up clumps. A modern 174 thousand cubic meter carrier will spend one to two days alongside. Add pilotage windows and weather. The backlog grows fast. Globally, the liquefied natural gas carrier orderbook is heavy through 2028 given Qatar’s North Field fleet, new Middle East volumes and continued Asian utility needs. Newbuild prices remain elevated by historical standards. Yard slots at the large Korean builders and select Chinese yards are largely spoken for in the 2026 to 2028 window.

For buyers and sellers this means two things. First, chartering needs to be part of the project critical path, not an afterthought. Second, loading rate upgrades and a third berth are not luxuries on multi train sites. They are insurance against idle full tanks and angry offtakers.

How buyers are contracting in 2025

The contracting map split in two this year. Asian buyers led by Japan, South Korea and China continued to secure 15 to 20 year free on board contracts indexed to Henry Hub or oil. That is the bedrock for financing. Portfolio players added flexibility by taking medium tenure deals and reserving diversions. European buyers tilted toward shorter terms and cargo optionality, often with destination free clauses and stronger take or pay thresholds.

A few motifs define the year:

-

Industrial Europe wants flexibility. Several utilities and power generators have signaled a preference for 10 to 15 year deals with clauses that allow resale into other basins when domestic demand is soft. The priority is balancing portfolios as pipe contracts expire and as the old assumption of Russian baseload fades.

-

Asia is reloading long. Japanese and South Korean buyers extended positions that roll beyond 2030, often seeking free on board to manage shipping fleets directly. Chinese buyers balanced long term commitments with tactical resales when tariffs bite or domestic demand softens.

-

Producer aligned deals. Upstream producers like EQT took direct positions in liquefaction offtake to connect wellhead to water. That model reduces basis risk and gives producers direct exposure to global prices.

The net result is healthy offtake cover for shovel ready projects and a more demanding commercial close for those still pre final investment decision. Contracts with real teeth on delivery schedules will be more than legal risk. They will drive execution discipline on site.

Methane intensity rules and what they mean for U.S. LNG

For exports into the European Union the timetable is now set. Reporting of methane frameworks begins with qualitative disclosures in 2025, monitoring and verification requirements attach to new or renewed contracts starting January 1, 2027 and methane intensity reporting arrives in 2028. In 2030, a maximum methane intensity threshold applies for new contracts, with national authorities enforcing compliance. The European Commission summarizes the steps in EU methane requirements for imports.

In the United States, the Environmental Protection Agency’s broad methane rule for oil and gas remains the umbrella, but the separate waste emissions charge created by statute has been rolled back through a joint congressional resolution, following the episode when Congress killed the methane fee. Developers should not read this as a free pass. Large European and Asian buyers will increasingly demand facility level measurement, reporting and verification across the supply chain from basin gathering to terminal flares, with third party audit. A credible methane strategy will be part of every request for proposal response.

Practical steps for compliance:

-

Meter and measure. Deploy continuous methane monitors at compressor stations, storage tanks and marine flares. Equip upstream supply with optical gas imaging and quantified leak detection and repair schedules. Tie data streams to your scheduling and cargo documentation.

-

Certify gas supply. Work with producers enrolled in recognized measurement frameworks. Use indexed pricing differentials to reward lower methane intensity. Build clauses that allow substitution of higher intensity gas with certified volumes.

-

Publish terminal baselines. Disclose methane intensity factors at the terminal, including compressor seals, boil off and flaring during commissioning. Buyers want numbers, not adjectives.

Litigation risk is now part of the critical path

Courtrooms matter as much as control rooms. Several approvals in 2024 and 2025 moved forward only after agencies supplemented environmental reviews focused on air quality, environmental justice and alternatives like carbon capture. In Louisiana, a state court recently sent a permit back for more climate analysis at an export site, pausing part of that timeline. Separately, federal litigation around air modeling, environmental justice and pipeline routes is ongoing for multiple projects. The message to sponsors is consistent. Build a litigation schedule with milestones for briefings, hearings and potential remands. If you are not modeling docket risk, you are guessing on in service dates.

The likely 2026 to 2030 buildout

Given permits, funding momentum and contractor capacity, a plausible sequence looks like this:

-

2026. Golden Pass begins phased exports. Plaquemines ramps Phase 1. Corpus Christi Stage 3 adds midscale trains. Rio Grande continues major civil and mechanical works. Feedgas expansions from Haynesville accelerate.

-

2027. CP2 reaches first cargoes if its pipeline and power islands synchronize with modular train delivery and commissioning. Port Arthur Phase 1 loads its first ships. Corpus Christi Stage 3 approaches full program completion. Rio Grande Train 1 pushes toward late year start.

-

2028. Port Arthur Phase 1 is fully in service. Corpus Christi Midscale 8 and 9 deliver added capacity. Rio Grande adds Trains 2 and 3. Texas LNG advances site construction if it hit its 2025 final investment decision. Commonwealth moves from site prep into peak construction pending resolution of state level challenges.

-

2029 to 2030. Port Arthur Phase 2 enters service in stages. Rio Grande Train 4, sanctioned in 2025, crosses the finish line in the second half of 2030. Additional brownfield increments at Sabine Pass or Corpus Christi continue to stack capacity.

The totals point to another doubling of U.S. liquefaction by decade end if execution holds. The limiting factors are not geology or demand. They are labor, long lead manufacturing and legal calendars.

Fast track playbook: how to seize the window without tripping

Moving fast and clean is a discipline. Sponsors, contractors and buyers can follow a common playbook that balances speed with resilience.

- Lock your critical path in this order

-

First, feedgas. Secure firm transport from at least two basins and finalize interconnect and meter station designs before final investment decision. Treat pipeline in service as the last immovable milestone before cooldown, not a parallel track.

-

Second, tanks and modules. Reserve storage tank fabrication slots and module yards early. Pair those reservations with enforceable delivery windows that align with the commissioning sequence.

-

Third, berth capacity and tugs. Plan for a third berth on multi train sites or a higher loading rate certification. Pre arrange tug availability and pilotage windows for start up months when demurrage risk is highest.

- Choose EPC terms to fit the market

-

Use hybrid pricing. Fix what the contractor can control and tie wage and commodity escalators to transparent indices with caps. Reserve owner contingency for the items that historically hit commissioning, including power systems, instrument air and nitrogen units.

-

Staff up early supervision. Pay for early placement of superintendents, quality control leads and safety officers months before peak manpower. These people compress schedules more than any extra crane.

- Engineer for commissioning and weather

-

Design the turnover. Sequence systems so the power island, utilities and safety systems hand over early. A terminal that can make and move nitrogen on day one of train start up will save weeks across a program.

-

Elevate and enclose. Raise critical electrical rooms and pump pads. Enclose ground flares and design storm water control for back to back events. One flooded substation can erase an entire season.

- De risk methane intensity and reporting from day one

-

Write measurement into contracts. Require continuous monitoring at the terminal and periodic third party audits of upstream producers. Build methane intensity thresholds into gas purchase agreements and adjust fees when thresholds are exceeded.

-

Create a buyer portal. Provide buyers with shipment specific greenhouse gas documentation that integrates pipeline, terminal and voyage emissions. Do it at launch, not in year three.

- Pre litigate the record

-

Over document air and environmental justice analysis. Use the most conservative monitors and model runs. Address alternatives such as carbon capture directly, and explain feasibility with cost and integration details.

-

Maintain a litigation critical path. Assume one remand cycle in your schedule. Preserve budget for supplemental environmental impact statements, expert witnesses and community engagement. Set up a standing table with local stakeholders and fishermen where complaints can be resolved before they ripen into lawsuits.

- Align commercial and physical flexibility

-

Offer offtake with operational windows. During start up months, structure delivery windows that recognize the realities of first fire and cooldown. Put collaborative cure periods into contracts so commissioning hiccups do not become arbitrations.

-

Keep optionality on shipping. Blend charter lengths across your portfolio and include options that let you upsize to meet berth constraints without paying spot premiums.

The bottom line

The late October approval of CP2 did not just add tonnage to a spreadsheet. It reset the tempo. Between 2026 and 2030 the United States can deliver a second step change in liquefied natural gas capacity if owners, contractors and buyers execute with discipline. The obstacles are real and specific. Labor, tank steel, modules, berths, pipelines and legal calendars each pose a distinct risk. None are mysterious. The winners will be the teams that treat those constraints as design inputs, not afterthoughts. Do that, and the next wave of U.S. cargoes will reach the water on time, with methane footprints measured and managed and contracts that endure beyond a single market cycle."