SoftBank’s $5.4B ABB buy primes LLM agents for factories

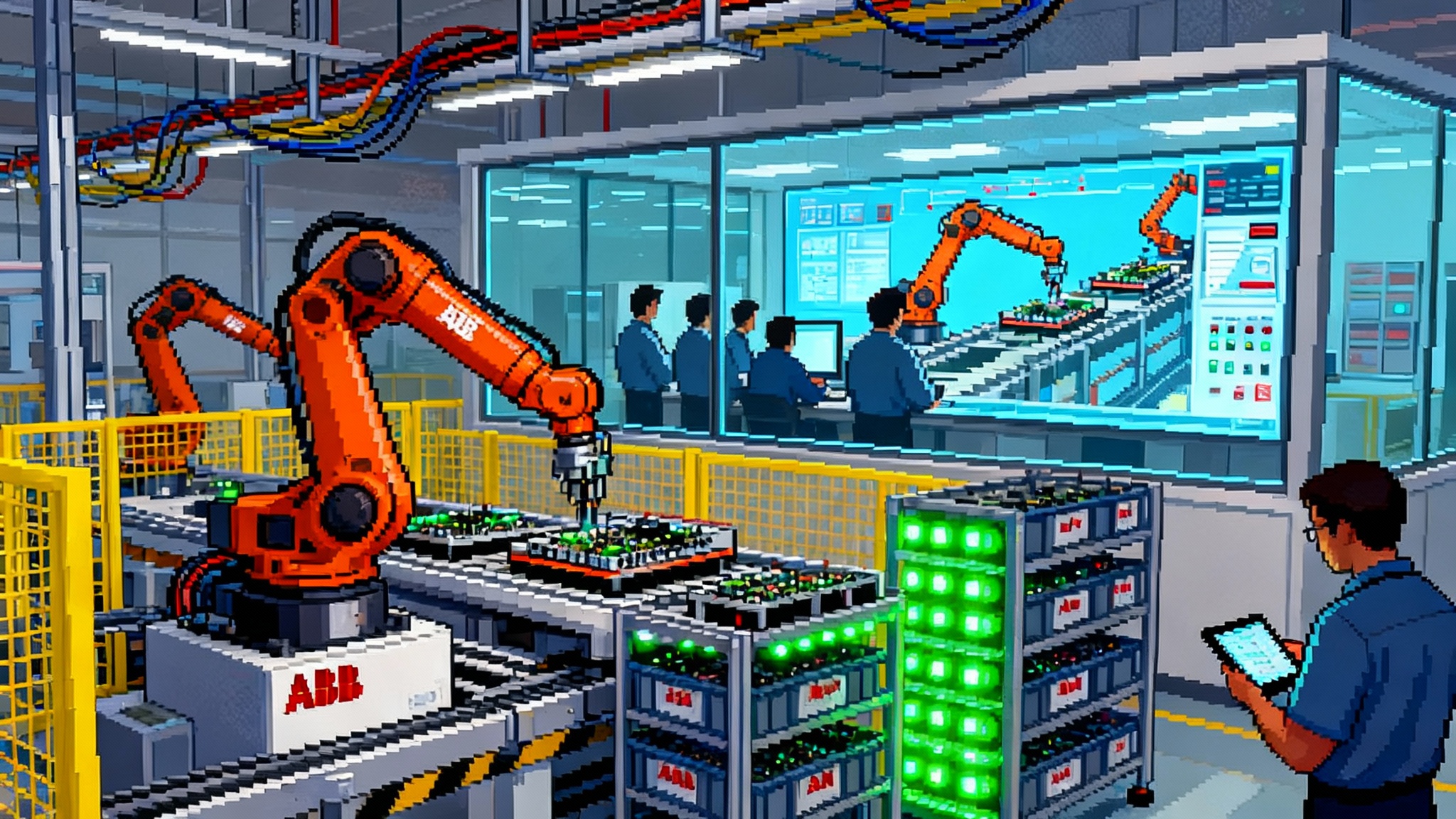

On October 8, 2025, SoftBank agreed to acquire ABB’s robotics division for $5.4 billion. The deal could push large language and vision models from the browser into factory cells, accelerating agentic automation.

The day factory agents got a green light

On October 8, 2025, SoftBank agreed to acquire ABB’s robotics division for about 5.4 billion dollars, a move ABB framed as a strategic divestment and SoftBank cast as a push into physical artificial intelligence. The announcement arrived with the precision of a production shift change: terms, timing, and a promise to combine ABB’s installed base and hardware know-how with SoftBank’s model-centric software bets. For the world of industrial automation, it reads like a starting pistol. ABB’s announcement on the deal sets the scope and timeline.

What changes with this single line on the scoreboard is not just ownership. It is the center of gravity for agents powered by large language models and vision-language models. After a year of browser-native agents that clicked buttons and filled out forms, the action is shifting to assembly lines, pick walls, and maintenance bays. We covered how browser-native agents arrive; SoftBank is putting money and distribution behind taking them to the floor.

From chat windows to torque wrenches

LLM means large language model. VLM means vision-language model. In the office, these systems learn tasks by reading instructions and observing screens. In the factory, they do something similar, but the screens are camera feeds, the instructions are standard operating procedures, and the keystrokes become robot motions.

Imagine the agent as a highly trained shift lead who can also read every manual in seconds, watch ten camera angles at once, and never gets tired. It reads a work order, inspects parts through cameras, plans a sequence, calls up a library of robot skills, and asks a safety interlock for permission at each step. This is not magic, it is a stack.

The emerging control stack for agentic robotics

To understand why the ABB deal matters, map the stack that is forming under these agents. Each layer is maturing, but only a few firms can combine them at scale inside real factories.

-

Perception layer. Multimodal sensing turns pixels and signals into usable facts. High-resolution stereo, time-of-flight depth cameras, tactile skins, torque sensors, radio frequency identification, and even sound are fused into a normalized state of the work cell. VLMs translate images and point clouds into object identities, poses, and quality judgments. The frontier here is consistency in uncontrolled light, dust, and reflective materials. In practice, manufacturers will standardize on a few camera and sensor kits that have known performance with ABB arms and grippers.

-

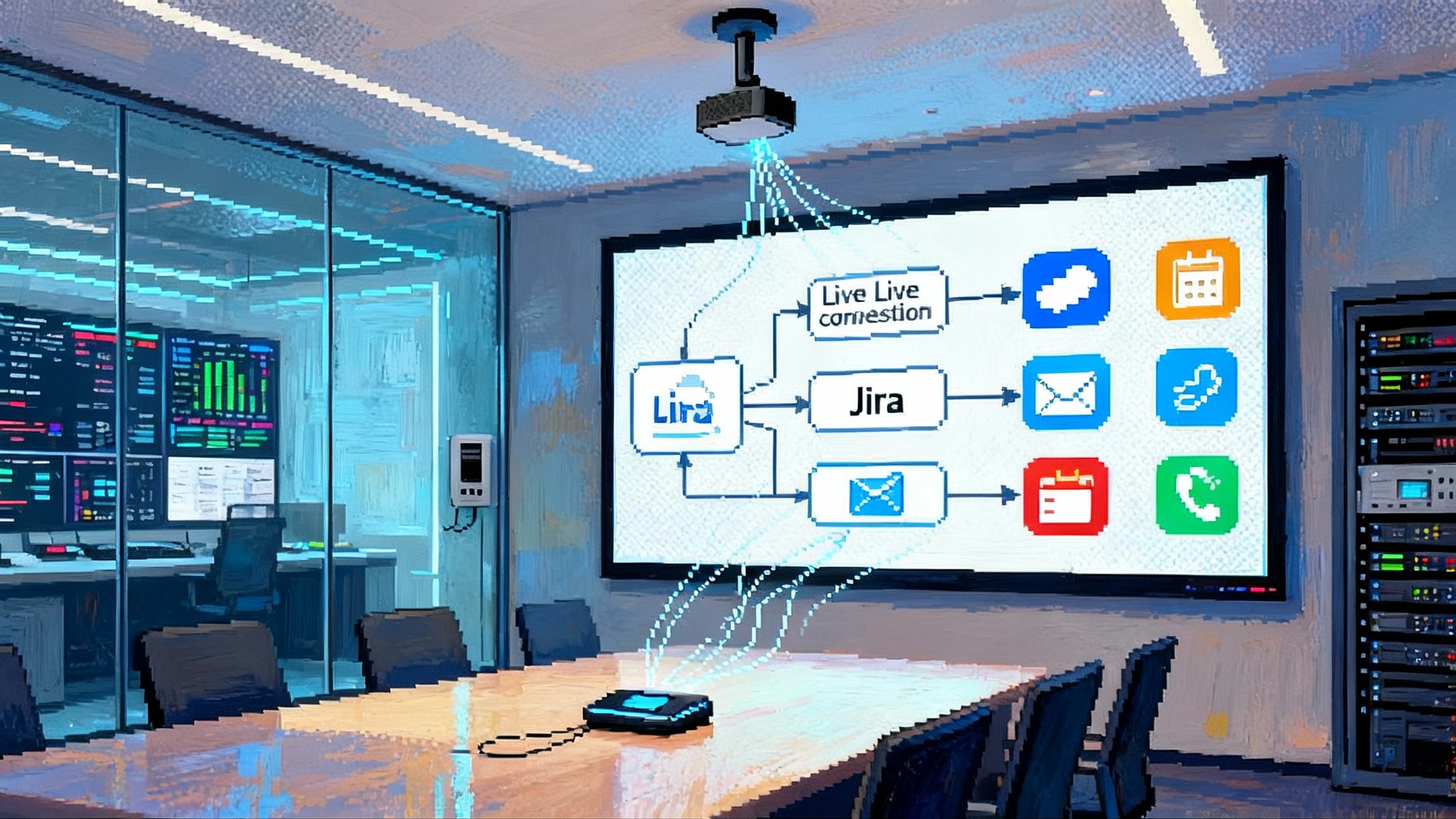

Planning and reasoning layer. Task planners powered by LLMs read goals, parse constraints, and choose which robot skill to call next. Think of this as the agent’s brain for deciding the next best action. It is not writing every motion. It delegates to the skills layer and verifies results from perception. Modern planners maintain a world model, track uncertainty, and use feedback. They also speak operations language. Give them a bill of materials, and they can translate that into the pick, place, screw, and test steps that a cell must perform. They can also explain their choices in plain English, which makes debugging and operator training faster. For software foundations, see how the agent runtime standard is taking shape.

-

Skill libraries. These are the motion primitives, grasps, insertions, and inspection routines that actually move hardware. They are callable like software functions, but they are grounded in real robot capabilities defined by kinematics, payload limits, and safety zones. Vendors already maintain libraries for common tasks. The switch now is to make them composable by agents. Think “tighten M3 screw to 0.6 newton meters with bit type PH1 at 120 revolutions per minute,” not “joint angle 32 degrees.” If SoftBank builds an app store for these, developers will ship skills the way mobile teams ship widgets.

-

Digital twins. Before a new skill touches metal, the agent tests it in simulation. A high-fidelity twin of the work cell simulates robot paths, collisions, cycle times, and line balancing. ABB has long offered RobotStudio and system-level simulation. Coupled with learned models, a twin becomes the agent’s rehearsal stage. Sim-to-real gaps still exist, especially with deformable materials or tightly toleranced insertions, but every closed loop shrinks that gap.

-

Safety and compliance. Industrial robots live under standards like ISO 10218 for robot safety and ISO 13849 for safety-related parts of control systems. The agent must prove it respects speed and separation monitoring, safe limited speed, and emergency stop behavior. Expect checklists to become executable tests, where each safety function has a traceable log and a digital certificate. This is also where human factors live, including collaborative modes and handover cues.

-

Orchestration and data plumbing. The agent integrates with manufacturing execution systems, enterprise resource planning, and quality management. It needs to fetch work orders, log serial numbers, and attach test results to the right lot. Interfaces like OPC Unified Architecture and Message Queuing Telemetry Transport will carry most of the messages. This layer is unglamorous, but it is where pilots become production. For the control-plane context, see how agent control planes go mainstream.

SoftBank’s purchase gives it two levers that pure-play software firms lack. First, a path to embed agents directly into robots and cells with ABB’s reach in automotive, electronics, and consumer goods. Second, a credible route to standardize how skills and twins are packaged, tested, and distributed across thousands of sites.

Why this deal could compress timelines by three to five years

Deals compress time when they remove the hardest bottlenecks. In industrial automation those bottlenecks are data access, distribution, and safety validation.

- Data access. ABB robots already capture forces, torques, positions, and quality signals. When a model can learn from a fleet, it improves faster. With SoftBank’s investment appetite, instrumented pilots can scale to multi-site deployments instead of living forever as proofs of concept.

- Distribution. Agents are useful only where they run. Installing software into a device that already sits in a factory beats selling a separate agent box. ABB’s installed base offers a ready host.

- Safety validation. If safety test suites are co-designed with the robot maker, approval cycles shorten. The same test harnesses can be reused across customers and lines. That makes regulators and insurers more comfortable, which in turn accelerates purchase decisions.

Reuters reported that the transaction is expected to close in mid-to-late 2026, which gives a runway for integration and early product launches. Reuters coverage of the deal points to both the valuation and the operating context.

Near-term deployments: three wedges that win now

The first wave of agentic deployments will target jobs with high variability and heavy documentation, where the cost of downtime is high and the geometry is manageable. Three wedges stand out.

- Electronics assembly and test

- The job. Final assembly of consumer and enterprise electronics, including fastening, connector insertions, thermal pad placement, and end-of-line tests.

- Why agents help. Product lifecycles are short. New models arrive quickly. An agent that can read a new work instruction, watch a few demonstrations, and adjust tool paths can bring a cell up in days rather than weeks. VLMs can spot bent pins or misaligned labels. LLMs can sequence steps and select skills from a library. Digital twins can tune cycle times before the first unit is built.

- What to deploy. Camera kits with controlled lighting, standardized grippers with quick-change tool changers, and a set of certified skills for screwdriving, clip fastening, and test rig control. Use a twin to pre-validate paths and safety zones. Keep an operator in the loop for exception handling and allow the agent to request help with a one-button escalation.

- Payoff. A 20 to 40 percent reduction in changeover time for new products. Scrap reduction on delicate connectors. Better traceability as the agent logs torque curves and test signatures against serial numbers.

- Last-meter logistics inside the building

- The job. The final short moves in warehouses and factories that fall between conveyors and loading docks: put walls, kitting, and pack-out.

- Why agents help. Order mixes change by the hour. Agents can adapt to new stock keeping units by reading packaging drawings, watching a few picks, and composing grasping and placing routines. They can ask for a new corrugate size when an article does not fit and replan the path when a teammate cart blocks the lane.

- What to deploy. Mobile bases paired with collaborative arms for dense work cells, high-friction grippers for polybags and cartons, and perception tuned for shiny film and clear plastic. Agents should integrate with warehouse management systems to anticipate surges and pre-stage totes. Safety must enforce speed limits in shared aisles and monitor separation from people.

- Payoff. Higher picks per hour in variable environments, fewer blocked lanes, and lower training time for seasonal peaks.

- Predictive and prescriptive maintenance

- The job. Diagnosing faults in cells, recommending replacements, and guiding technicians through repairs.

- Why agents help. Maintenance binds documentation, history, and real-time signals. LLMs excel at retrieval and reasoning across manuals, logs, and diagrams. VLMs can compare a live camera view to a healthy template and highlight wear on belts or chips on cutting tools.

- What to deploy. A centralized maintenance agent tied to supervisory control and data acquisition and robot controllers, with access to parts catalogs and past interventions. Equip the floor with ruggedized tablets so technicians can accept or reject the agent’s step-by-step plan. Use twins to simulate the repair sequence and confirm that a change in a jig or fence does not violate safety.

- Payoff. Faster mean time to repair, fewer repeat faults, and a growing knowledge base that helps new technicians ramp faster.

The agent marketplace: from pilot skills to a catalog

A marketplace for robot skills will look more like a parts catalog than an app store, but the economics are similar.

- What gets sold. Verified skills, perception packs, and twin templates. For example, a vendor might sell a “flex-cable insertion skill” certified for two arm models and three grippers, with parameters for cable stiffness and connector tolerances. A systems integrator might sell a “two-station end-of-line test harness” that includes recipes for common instruments and a twin of a standard cell layout.

- Who participates. Robot makers and gripper vendors publish official drivers and safety functions. Third parties publish skills and perception modules that pass compliance gates. Integrators bundle these into ready cells. Manufacturers contribute private skills to their own internal catalogs.

- How it is governed. Every asset carries metadata: safety classification, compatible hardware, cycle-time benchmarks, and version history. A vendor score shows mean time between failure in the field and the number of successful deployments. Regression tests run in the cloud against a suite of twins before any update is allowed into a live plant.

- How revenue flows. Per-skill licenses with usage-based pricing tied to cycles or hours, with volume caps for predictable budgeting. Maintenance subscriptions cover updates to keep up with new robot firmware and safety standards. Distribution fees fund the marketplace operator’s testing infrastructure.

SoftBank can accelerate this by bundling marketplace distribution with the sale of ABB arms and controllers. If a cell ships with a skill runtime, the marketplace is one click away. That lowers the barrier for developers and increases variety for customers.

How manufacturers can move now

Even before the transaction closes, leaders can prepare their plants and teams for agentic automation.

- Standardize sensing. Pick a camera and lighting kit per cell type and stick with it. Consistency beats a small gain in sensor quality. Agents learn faster when inputs are uniform.

- Instrument for data. Ensure robots and cells log forces, torques, cycle counts, and failures to a time-synchronized data store. Label events with the right context. Training data beats clever prompts every time.

- Write procedures for machines and people. Turn the best technician’s tacit knowledge into structured steps that an agent can parse. Use the same words for the same actions. Small vocabulary discipline pays off.

- Pilot with a twin. Create a digital twin of at least one critical cell and run a closed loop from plan to sim to floor to sim. Make the twin a first-class artifact in engineering reviews.

- Define guardrails. Decide which tasks must always require human consent, which can run autonomously within fences, and which are out of bounds for the near term.

- Negotiate skill ownership. If you pay an integrator to develop a process-specific skill, ensure you own the right to reuse it across your plants. A good contract saves you from vendor lock-in later.

What startups and integrators should build

- Thin, robust skills that are hardware-conscious. Focus on tasks with clear tolerances and high repeat value. Aim for fast time to value rather than academic novelty.

- Perception packs for nasty edge cases. Shiny plastics, cloth, clear glass, and deformable cables are gaps that still cause downtime. Solve one well and prove it across sites.

- Twin templates that capture real constraints. Empty boxes are not useful. Include guarded spaces, realistic conveyor speeds, and robot-to-robot interference. Provide cycle-time calculators and quick line balancing tools.

- Safety validation as a service. Offer third-party certification and routine regression testing so customers can adopt skills with confidence.

Policy and safety: specific actions that reduce risk

- Encourage independent safety test suites. Publicly funded labs can host standard cells with instrumented fences, cobots, and human factors measurement to validate agent behavior against ISO norms. Publish de-identified results.

- Modernize training incentives. Offer tax credits tied to measured upskilling outcomes for technicians who learn to supervise agentic cells. Tie credits to completion of industry-recognized modules.

- Require security basics for connected robots. Mandate signed binaries, role-based access control, and segmented networks for any robot connected to cloud services. Audits should focus on these basics before exotic threats.

What could still go wrong

Consolidation helps execution, but it raises risks.

- Platform lock-in. A single vendor stack can trap manufacturers. Countermeasure: demand open interfaces and escrow arrangements for critical skills.

- Safety validation debt. Shipping fast without repeatable safety tests creates future recalls. Countermeasure: treat safety test suites like unit tests in software, and require them for every release.

- Over-reliance on frontier models. If a planner fails silently, a product gets damaged or a fixture breaks. Countermeasure: enforce confidence thresholds, attach uncertainty to every decision, and halt when doubt is high.

- Workforce mismatch. Agents change job content. Countermeasure: pair every pilot with an upskilling plan and create a clear role for human override that is respected on the floor.

The strategic meaning of SoftBank’s move

The deal gives SoftBank three capabilities that few can assemble quickly: a global sales channel into factories, a fleet of robots that can host an agent runtime, and a reason to standardize how skills are packaged and certified. That changes the economics of industrial agents.

Picture a near future in which a process engineer clicks a marketplace tile for a new connector insertion skill, runs a twin, and deploys the update to twelve cells overnight. The agent explains what changed, shows a trace of safety checks, and asks the operator to approve the first cycles. No one files a ticket. No one waits three weeks for a custom integration. This is what three to five years of timeline compression feels like on the floor.

The takeaway

There have been many promises that artificial intelligence would leave the screen and grip a tool. On October 8, 2025, that promise got a manufacturer and a budget. If SoftBank pairs ABB’s hardware and customer trust with a disciplined agent stack, the next wave of automation will look less like a robotics research demo and more like an everyday software rollout. The winners will be the teams that standardize sensors, write procedures a machine can read, and treat digital twins and safety tests as part of the product. The fuse is lit. The line is moving.