Starship Flight 11 Turns the Corner on Orbital Refueling

Flight 11 staged cleanly, flew more than an hour, and ended with two guided splashdowns. The next prototype adds refueling hardware and tougher tiles, setting up a 2026 demo that could pull Artemis work forward.

The night SpaceX quietly changed the scale of space logistics

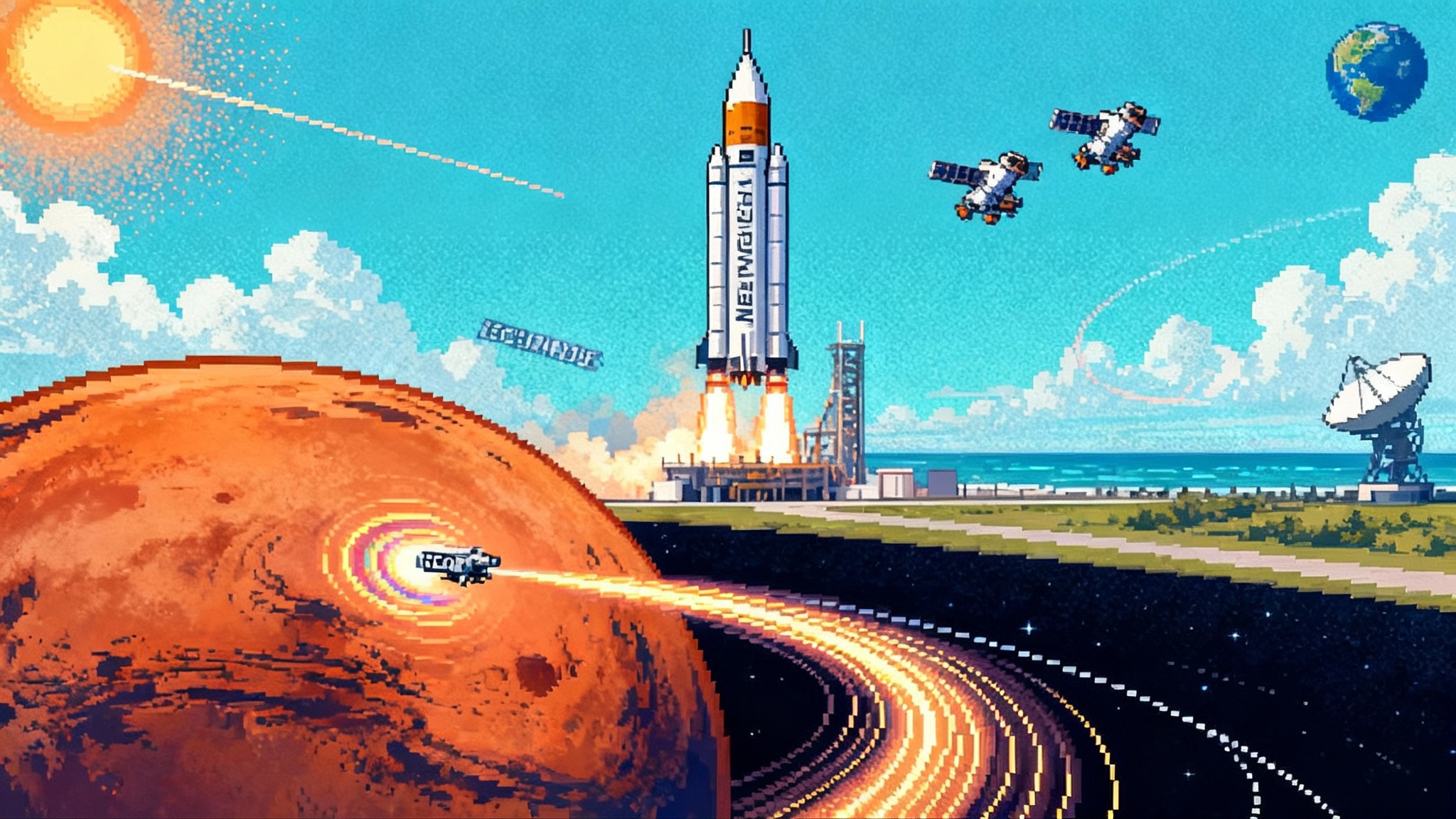

On October 13, 2025, SpaceX’s eleventh Starship test lifted off from Starbase, Texas, and checked off a list that had eluded the program for years. The Super Heavy booster separated crisply, flew a controlled descent, and splashed down in the Gulf of Mexico. The upper stage completed more than an hour of flight, performed an engine relight and a dynamic banking maneuver, then splashed down in the Indian Ocean. It even carried and released simulated payloads to practice deployment timing. The performance was not a stunt. It was a systems test, and it worked. If you want the sober version, read the Reuters flight report. The takeaway is simple. Flight 11 moved Starship from spectacular experiment to dependable platform.

What changed on this flight was not any single moment, but the absence of drama. Hot staging behaved. The computers shepherded dozens of engines through ascent and reentry without losing the thread. The upper stage stayed healthy long enough to complete full mission objectives and then some. When a test article survives its own test plan, engineers gain the right to build something harder next.

What Flight 11 actually proved

Three achievements from Flight 11 matter most for the future of lunar logistics.

-

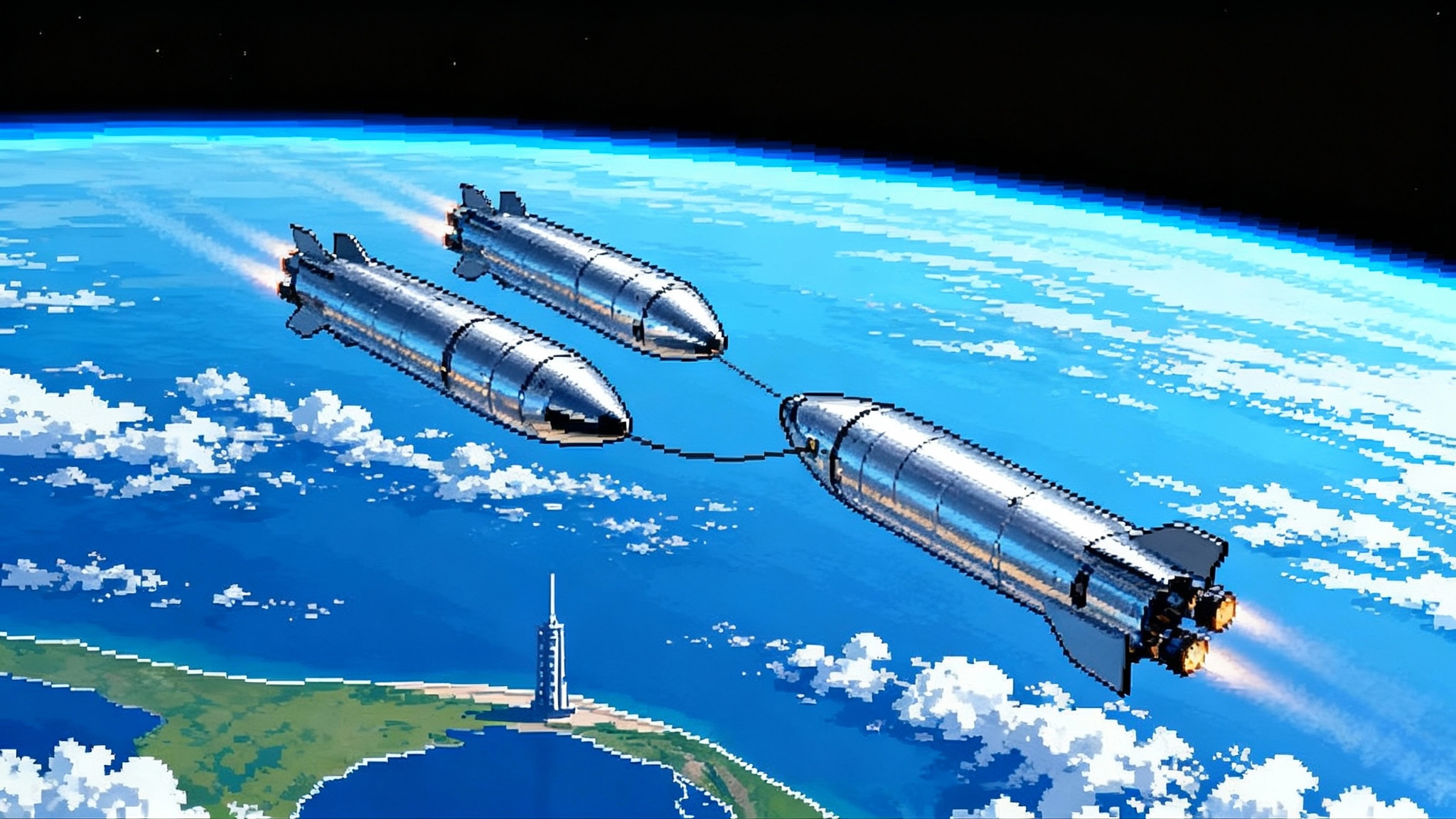

Clean staging at scale. Separating a fully fueled stainless steel upper stage while the booster is still firing sounds like a recipe for chaos. It works because the upper stage ignites while attached, then the interstage ring lets go. Picture two train cars on parallel tracks where the front car starts pulling before the coupler opens. The tug reduces jolts and keeps propellant settled in the tanks. Flight 11 repeated this at full power and handed the upper stage a stable start.

-

Long duration in space with control authority to spare. The upper stage flew for roughly one hour and six minutes, then executed a deliberate descent that looked more like a test pilot returning to the pattern than a tumbling hulk. Why it matters: orbital refueling demands long coast phases with precise attitude control. The vehicle must hold a gentle, steady orientation while two massive ships touch, latch, equalize pressures, and move cryogenic fluids without bubbles. If you cannot hold attitude for an hour, you cannot hold it for a day.

-

Controlled water landings for both stages. Recovery was not the goal. Data was. Controlled splashdowns mean the guidance, navigation, and control system can fly a scripted profile right to the end. That is the same quality you need to line up with a docking axis at a depot. If you can hit a rectangle in the ocean you can hit a docking ring in orbit.

None of these are glamorous in isolation. Together, they reduce uncertainty. They convert arguments about feasibility into spreadsheets about throughput.

The upgraded prototype: plumbing, protection, and patience

SpaceX now pivots to an upgraded Starship and booster pair tailored for deep space tasks. Three changes are worth translating into plain English.

-

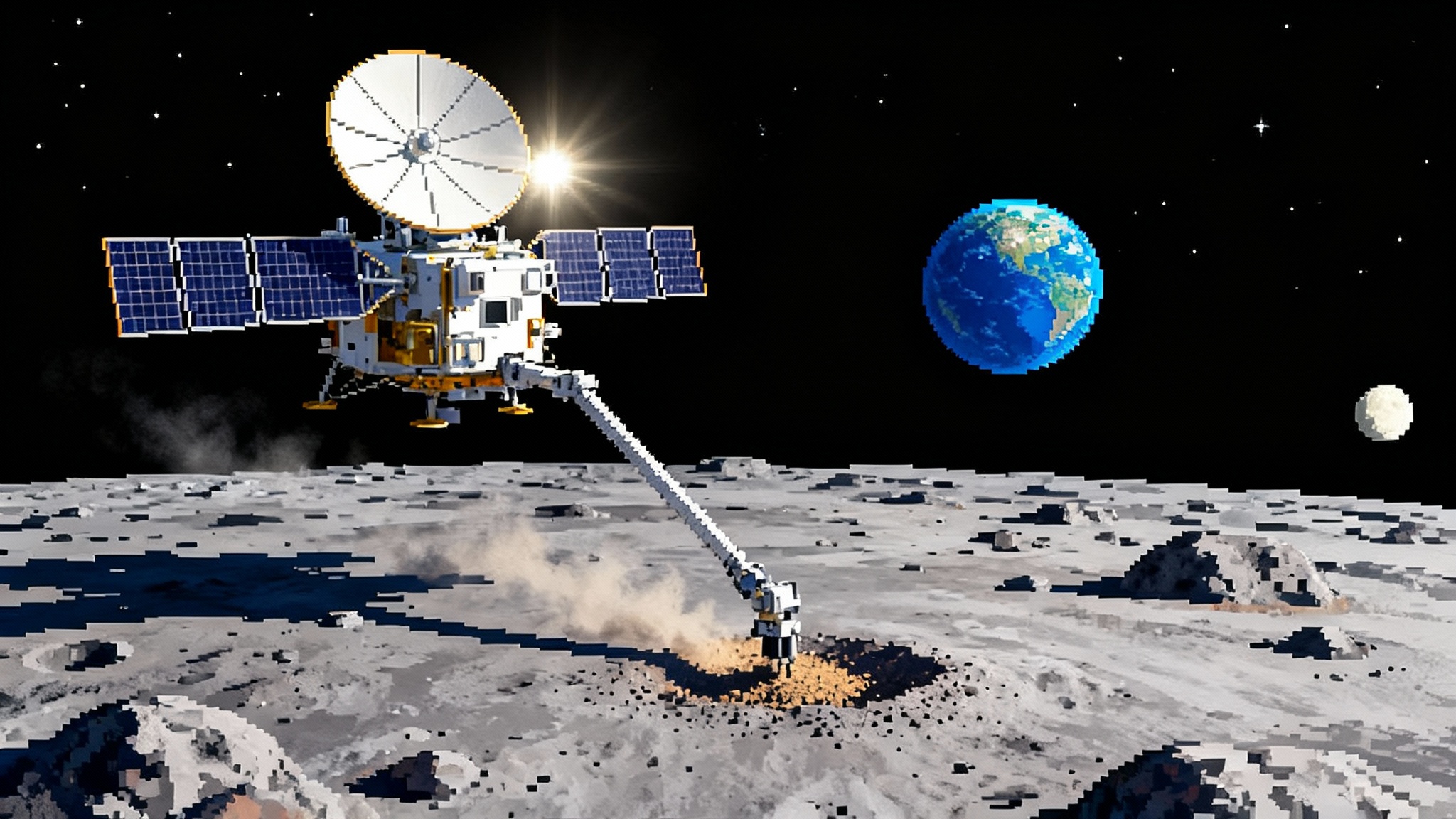

On orbit propellant transfer hardware. This is not a single gadget. Think of a whole set of parts working together. There are docking adapters so two ships can align and connect. There are quick disconnects that seal like the fuel hose at a gas station, only they must work in vacuum at liquid oxygen and liquid methane temperatures. There are vacuum jacketed transfer lines that act like thermos bottles to keep everything cold. There are sensors and valves that meter flow, vent gas safely, and prevent hammering and cavitation. All of it must be designed for zero gravity where liquids refuse to settle on the bottom.

-

Tougher thermal protection system. Thermal protection system means the heat shield. Starship uses thousands of ceramic tiles to keep its steel skin from overheating. The upgraded vehicle gets tiles with higher damage tolerance and improved mounting. Engineers are learning where tiles erode and where they crack, then redesigning tile size, backing, and attachment in those zones. You saw evidence on Flight 11 when SpaceX intentionally removed tiles in select areas to test margins, then used the descent as a wind tunnel with flames. The point is not to scorch the vehicle. The point is to map the envelope so the next version survives it.

-

Longer life on orbit. Refueling is not a sprint. One ship may have to wait in low Earth orbit for weeks while tankers launch, transfer propellant, and depart. Long life on orbit requires more power, more battery capacity, and better insulation to keep the cryogenic propellants from boiling away. NASA has already flagged this endurance requirement. The agency notes that internal tank to tank transfer within Starship was completed during an earlier flight test and that more robust on orbit operations are the next step, as described in a NASA propellant transfer note.

If Flight 11 was about confidence, the upgraded prototype is about interfaces. You can only move lunar scale cargo if every connection in the chain behaves like a factory machine, not an expedition experiment.

Why a 2026 refueling demo would compress Artemis timelines

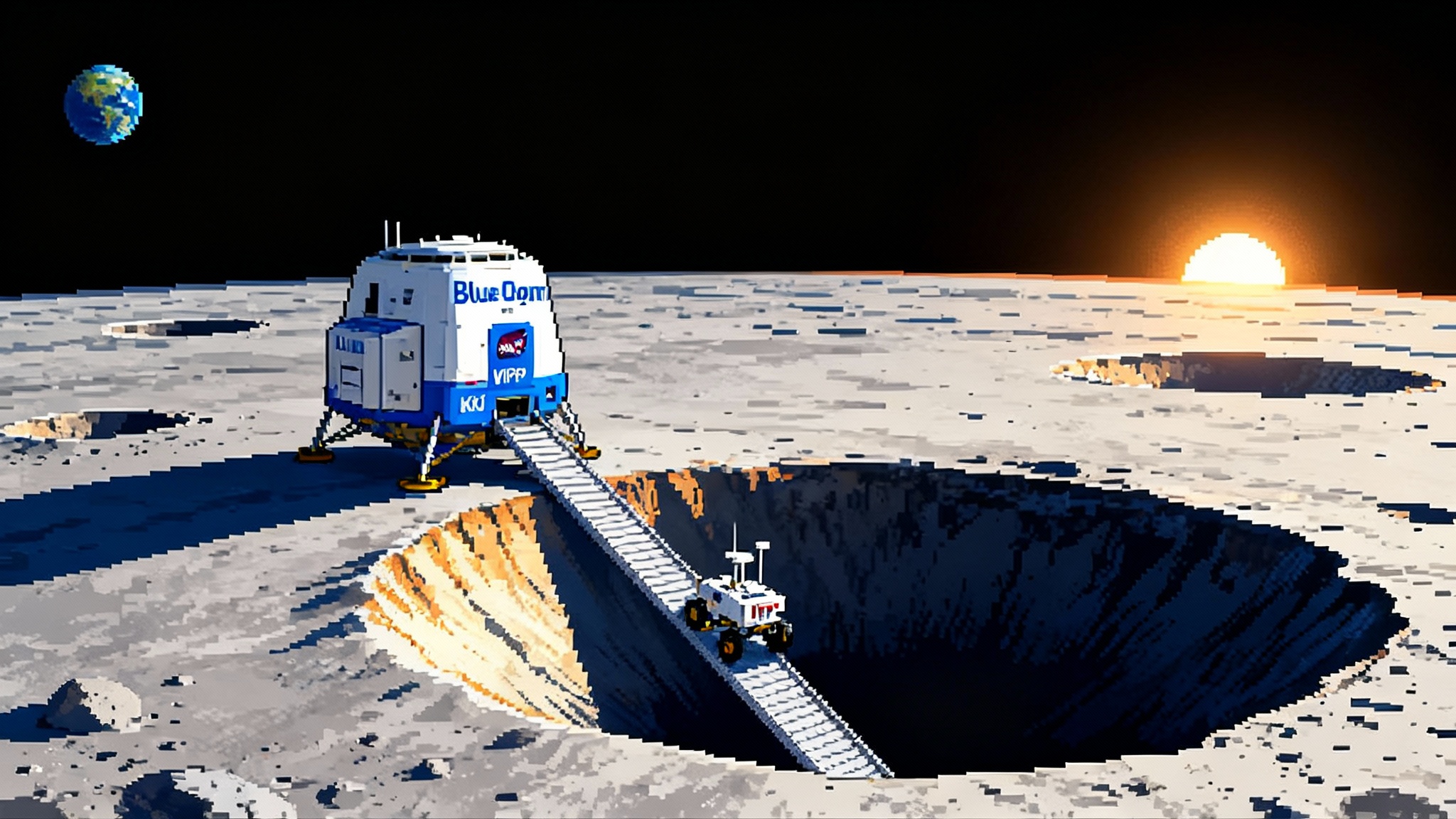

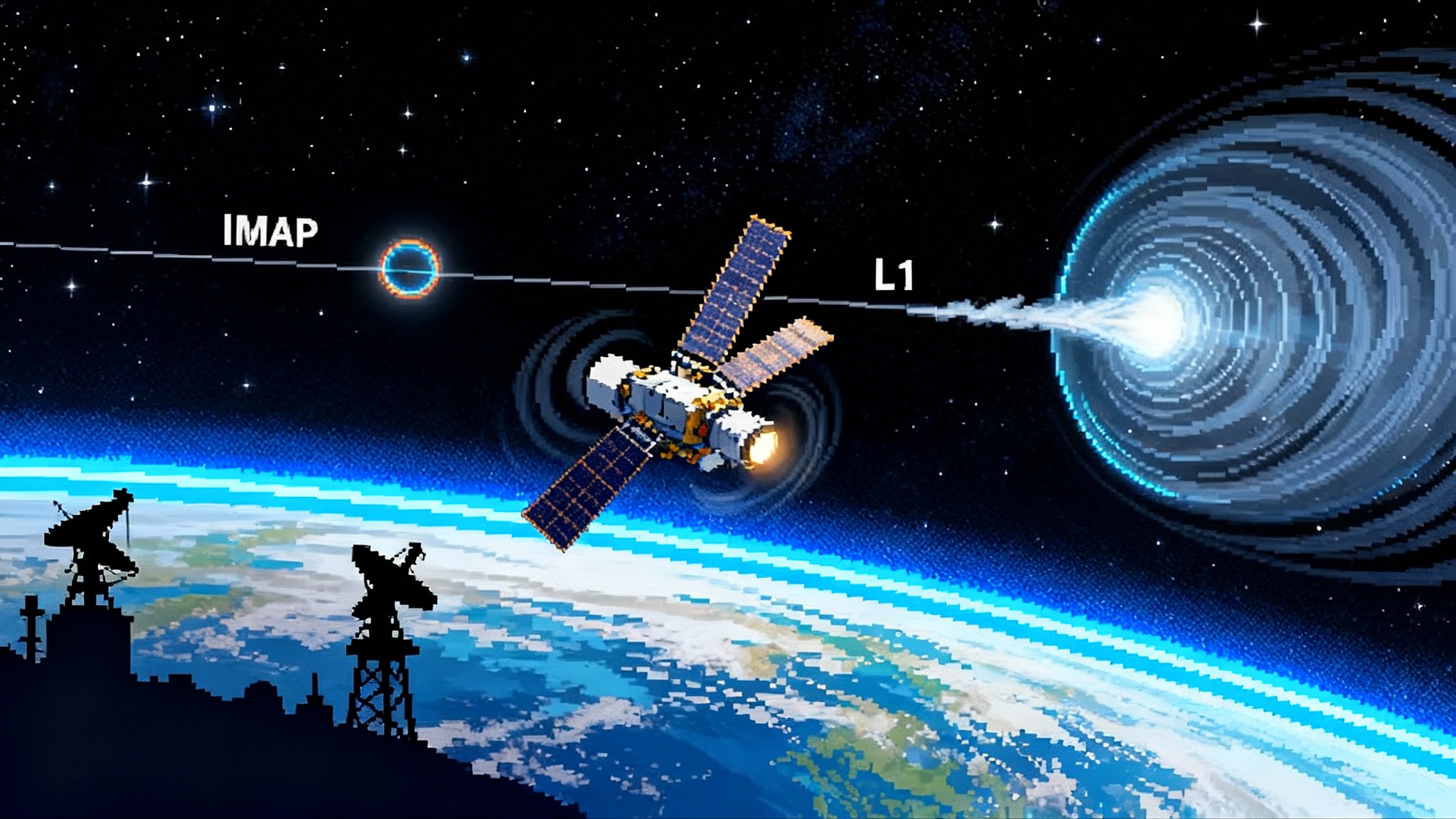

NASA’s Artemis plan relies on a Starship lander that reaches the Moon only after refueling in low Earth orbit. The bottleneck is not how fast you can launch one big rocket. The bottleneck is whether you can stack multiple tanker flights into one coherent transfer sequence that leaves the lander full enough to go to the Moon and back.

A ship to ship propellant transfer demo in 2026 would pull multiple schedule risks forward and burn them down in one go. Here is the mechanism.

-

It validates docking hardware and autonomy logic. Rendezvous and proximity operations are one of the highest risk parts of any mission. A successful demo lets NASA and SpaceX finalize docking geometries, guidance laws, lighting, and sensor placement. That locks the interface so suppliers can cut metal for flight ready parts without worrying the design will churn.

-

It measures boil off and fluid behavior at scale. Cryogenic liquids hate being told to sit still. They stratify. They form bubbles. They prefer to evaporate if given any heat leak at all. Internal tank transfers on earlier flights answered first order questions, but only ship to ship operations expose how ullage gas moves across a connected plumbing path and how thermal gradients affect flow. Once those numbers are real, mission designers can compute exactly how many tanker launches are required and how tight the timing must be.

-

It exercises range and ground cadence under real constraints. A genuine refueling sequence needs two launches within a few weeks, sometimes less. A demo forces the company to coordinate licenses, range availability, pad refurbishment, and vehicle turnaround at a pace that resembles operations. The lesson learned here is not just engineering. It is logistics. That data supports a credible plan for multi launch campaigns that Artemis will need.

Do those three things in 2026 and you eliminate the largest unknowns that push critical design reviews to the right. That is how a demo compresses timelines. It does not magically make years vanish. It prevents months from slipping.

The door this opens: routine cislunar cargo

Once refueling is real, routine cislunar cargo stops being a PowerPoint slide. The economics shift because Starship can trade propellant for payload. Empty Starship can reach orbit with tank margins and then drink from a tanker before heading for the Moon. That lets operators send bulky hardware that never fit economically on legacy rockets. Think pressurized modules for Gateway, heavy surface power rigs, large rovers with real wheels and suspensions, and pallets of supplies that reduce dependence on tightly packed small deliveries. You can even pre stage missions like VIPER south pole delivery and bring up communications assets for a lunar internet testbed.

Uncrewed cargo runs also allow a new operating mode. Instead of flying precious crewed missions with extra technical risk, you can push upgrades and test equipment to lunar orbit or the surface ahead of people. Staging works on Earth for mountaineers. The same idea works in space. The depot in low Earth orbit and the staging point in lunar orbit become the equivalent of base camps. That is how exploration becomes logistics.

The risks that still matter

-

Regulatory and environmental approvals. The Federal Aviation Administration issues launch licenses and modifies them as missions evolve. New hardware, higher flight rates, and different splashdown corridors all need analysis. Environmental reviews can gate work at Starbase and at Florida launch sites. None of this is a showstopper, but it is real schedule friction. The mitigation is early application, transparent data sharing, and building pad infrastructure that reduces noise and debris.

-

Range and cadence. A refueling demo means two big launches with a tight separation. Weather, competing missions, and maintenance windows will fight that plan. The Eastern Range in Florida and the range supporting Starbase are busy. The mitigation is multiple pads, rapid refurbishment, and a playbook that treats every launch like a train departure, not a one off event.

-

Cryogenic fluid management. Boil off, slosh, and gas ingestion are the villains. Every connector and line must be insulated. The vehicles need thrusters and flight rules to settle propellants during each transfer. Sensors must discriminate liquid from gas. If you have ever tried to pour a slushie through a straw while riding in a car, you understand the problem. The fix is a blend of better insulation, smarter valves, and gentle, scripted attitude changes that coax liquids where they need to go.

-

Thermal protection margin. Tiles that survive reentry intact are not a nice to have. They are the difference between a reusable system and a one use prototype. The upgraded tiles and mounts must prove that they can tolerate multiple flights. Until then, recovery remains limited and costs stay higher than the end goal.

-

Systems integration. Docking, transfer, avionics, and guidance all have to interlock. A leak detector that trips at the wrong time can abort a transfer and leave the lander short. Build tests are the remedy. That means using ground mockups with flight like plumbing and running them like a production line.

A six to twelve month roadmap of tests to watch

Here is a concrete calendar for the next four quarters and what to look for at each step. The dates are approximate and will shift, but the sequence is the point.

-

Q4 2025 to Q1 2026: First flight of the upgraded Starship and Super Heavy. Watch for two things. First, the presence of new external plumbing and docking hardware on the ship side. Second, tile survivability on a more aggressive reentry profile. If the vehicle repeats the clean staging and long duration flight from Flight 11 while carrying the new hardware, that signals integration is on track.

-

Early 2026: Ground cryogenic transfer exercises with flight like hardware. Expect SpaceX to show test articles of docking adapters, quick disconnects, and vacuum jacketed lines in a ground stand that can chill liquids and cycle connections. The success metric is repeatable, bubble free transfer and clean disconnects without frost bridges or valve chatter.

-

Early to mid 2026: Long duration on orbit test. This is the endurance run. A target ship coasts for multiple weeks with augmented power and thicker insulation. What to look for in public updates: roll control authority after days in space, battery state of charge trends, and temperature telemetry that shows low boil off rates. Without a proven endurance window, a refueling demo will be schedule constrained to unrealistically tight timing.

-

Mid 2026: Rendezvous and proximity operations shakedown. Even before a full transfer, SpaceX can fly a chaser ship to a hold position near a target and practice approach corridors, lighting, and sensor fusion. The goal is to demonstrate stable station keeping and a smooth retreat on command. If this goes well, docking becomes a risk reduction task rather than a first time event.

-

Mid to late 2026: First ship to ship propellant transfer demonstration. This is the big one. A target ship launches first and waits. A tanker follows within a few weeks. They dock and move a meaningful quantity of cryogenic propellant. The bar is not moving every last kilogram. The bar is showing smooth startup, stable flow, accurate metering, and clean shutdown with clear margins. Coupled with previous endurance and proximity tests, this would validate the core logistics model for Artemis.

-

Late 2026: Booster recovery experiments at higher fidelity. Whether the company attempts a catch at the tower or continues hovering splashdowns, the focus will be on reuse steps that cut turnaround time. Reflight of a booster with minimal refurbishment is the signal that cadence can climb.

-

Throughout 2026: Range and pad infrastructure expansion. Watch for the second Starbase tower coming online and Florida pad milestones. The visible signs are tower segment stacking and tank farm activation. The invisible sign is a rising tempo of static fires and wet dress rehearsals that do not slip.

How to use this roadmap

Tie each test to a question you care about. If you are tracking the Artemis schedule, the endurance run and the transfer demo are the gates. If you care about cost per kilogram to lunar orbit, booster reusability and pad cadence are your leading indicators. If you are a supplier, the appearance of flight like docking hardware is your cue that interface definitions are stable.

What this means for Artemis

NASA’s current planning targets a crewed lunar landing in 2027. A successful 2026 transfer demo would not guarantee that date. It would make it plausible by eliminating the single largest unknown and allowing teams to lock designs and shift effort into operations. It would also enable uncrewed cargo runs that pre position equipment, which lowers risk for any crewed attempt that follows. That is how timelines compress in the real world. You remove the reasons people need to wait.

The turning point, explained

Programs usually have a moment when the story stops being whether something can work and starts being how to scale it. Flight 11 was that moment for Starship. Clean staging. Long duration control. Two guided splashdowns. The next prototype aims squarely at the hard part, which is moving super cold propellant between two giant ships in space while everything stays calm. If the 2026 demo plays out, Artemis stops sounding like a juggling act and starts looking like a supply chain. That is the pivot from spectacular to routine, which is the only path to building a real economy between Earth and the Moon.