2025's Hypersonic Tipping Point: Dark Eagle and Mobile Strike

Late 2025 marks the shift from demos to fielded hypersonics. The Army is arming its first Dark Eagle battery as startups push cheaper hypersonic rounds onto mobile launchers like HIMARS. Here is what changes next.

The week hypersonics left the lab

If you track long-range strike, circle late 2025. After years of test windows, program resets, and range closures, the U.S. Army has begun arming its first Dark Eagle battery with operational rounds, closing out delivery by year’s end according to the program’s lead. That milestone turns hypersonics from a promise into a tool that commanders can plan around, not just brief about. It also lands alongside a different kind of breakthrough: contracts that bring lower-cost, startup-built hypersonic strike onto the Army’s existing mobile launchers, the same truck-mounted systems that have reshaped ground warfare since 2022. Together, these events form a hinge in the story. A capability once tied to scarce test ranges and bespoke industrial lines is moving onto roads, ramps, and existing tactical units.

The contrast shows up clearly in two headlines. First, the Army’s hypersonic battery at Joint Base Lewis-McChord is receiving its full load of rounds in December, a program milestone that caps a bumpy test path and stabilizes production for reloads in 2026, as Army Times reports first battery. Second, defense startup Castelion disclosed contracts to integrate its Blackbeard hypersonic strike weapon with platforms like HIMARS, with a manufacturing model that targets thousands of rounds annually at hundreds of thousands of dollars per unit, according to Reuters on mobile integrations. One milestone equips a first-of-its-kind heavy hypersonic battery. The other points to mass on a different scale: lighter, cheaper, truck-mobile shots that move with the fight.

What actually changed in 2025

- Dark Eagle moved from training sets to live rounds. The Army’s first hypersonic unit already had its launchers, battery operations center, power, and comms. The missing piece was missiles. Those are now arriving in quantity, closing a long-running credibility gap between exercises and capability.

- Mobile integration pathways opened for new rounds. Instead of assuming a launcher must be purpose built for a massive two-stage booster, the Army is exploring weapons that fit in today’s pods and can be fired from dispersed trucks that already deploy by airlift or ship.

- Reusable hypersonic testbeds proved their value. Stratolaunch’s Talon-A vehicles have flown past Mach 5, been recovered, and flown again. That sounds like a flight-test details story. In practice it is a cost and cadence story, because reusability turns every flight into data that can be compared across missions without re-building the entire airframe.

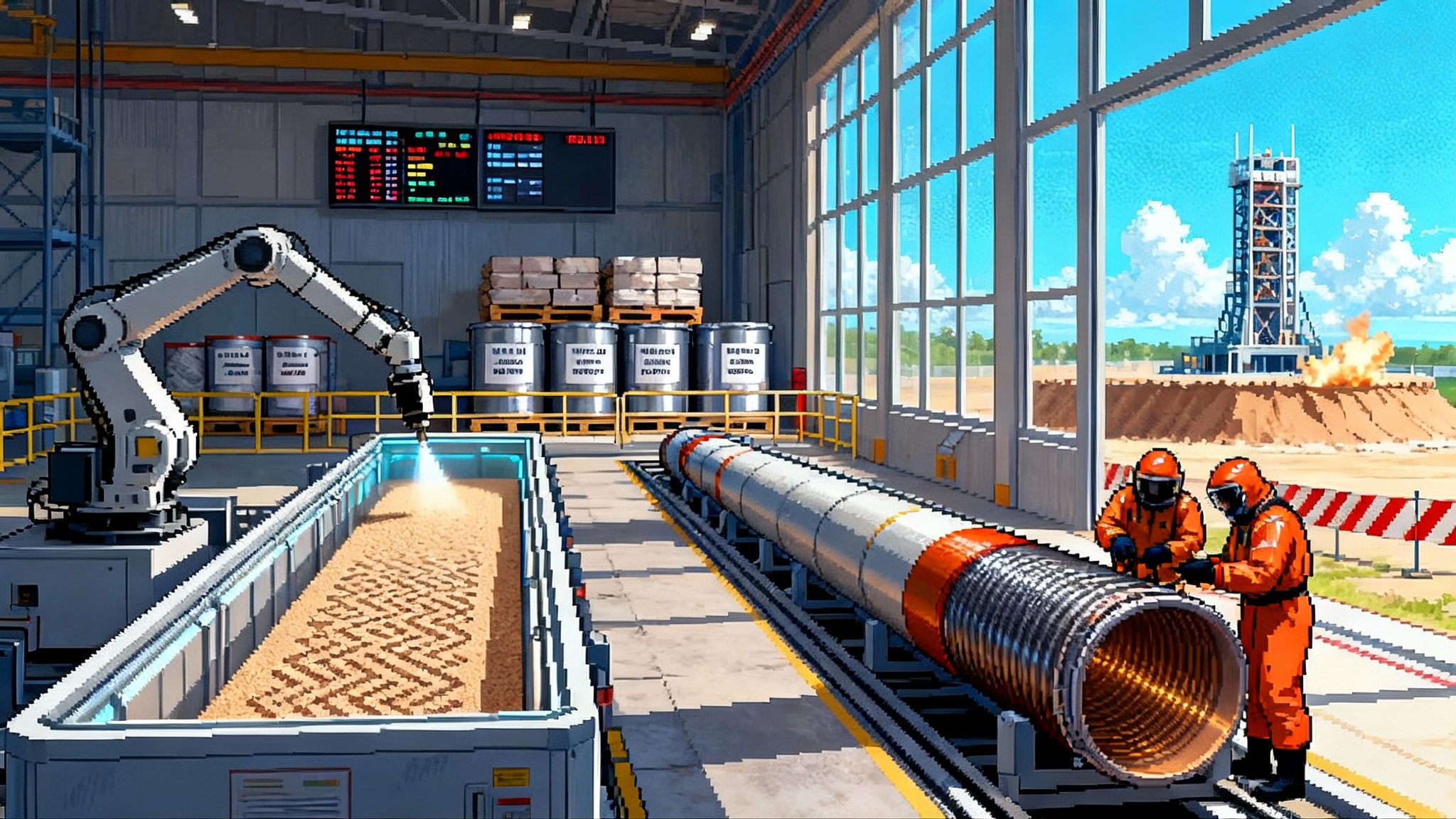

- The supply chain is scaling where it once stalled. Thermal protection systems, carbon-carbon composites, and solid rocket motors are well into a capacity build-out. For the motor side, see how printed propellants and new motors are changing timelines. Lines are adding furnaces, automated preform equipment, and additive manufacturing cells. The point is not only more parts. It is predictable schedules and unit costs that no longer jump when a single furnace goes offline.

Why costs and timelines are finally collapsing

Think of hypersonic development like learning a musical instrument. For years, programs paid for a new guitar every time they practiced. In 2025, they started renting a studio and playing the same guitar over and over. Three shifts are doing most of the work:

-

Reusable testbeds. Air-launched, recoverable vehicles let teams run A-B tests across flights. Swap one inlet ramp angle or a different ablative coupon, and fly again two months later with the same telemetry pack and the same airframe. That shrinks the time from idea to evidence and slashes the cost per data point. It also frees programs from the choke point of shared range schedules that used to stack up for a single high-stakes shot.

-

Modular propulsion. Startups are fielding storable liquid engines for testbeds and pursuing novel solid rocket motors for tactical rounds. The common theme is manufacturability. Storable engines trade a little peak performance for easy handling, throttle control, and repeatable production. Solid motors built with additive processes cut tooling time and let teams tune propellant grains quickly. Even material choices are shifting toward recipes that print or cure faster without trading away temperature margins.

-

Industrial-base investment. The shakiest pieces of the puzzle were carbon-carbon parts and high-temperature composites, which act like the vehicle’s thermal skeleton. Funding to add furnaces, layup automation, and inspection tooling is turning six-month bottlenecks into planned queues. That turns programs from schedule takers into schedule setters.

The combined effect is brutal on cost. When a team can fly four or five times in a year, with the same reusable vehicle carrying swappable experiments, it accumulates the kind of reliability evidence that once required three calendar years and a stack of risk reviews. When parts arrive from multiple domestic facilities instead of one specialty shop, the pricing conversation changes from “if” to “how many.”

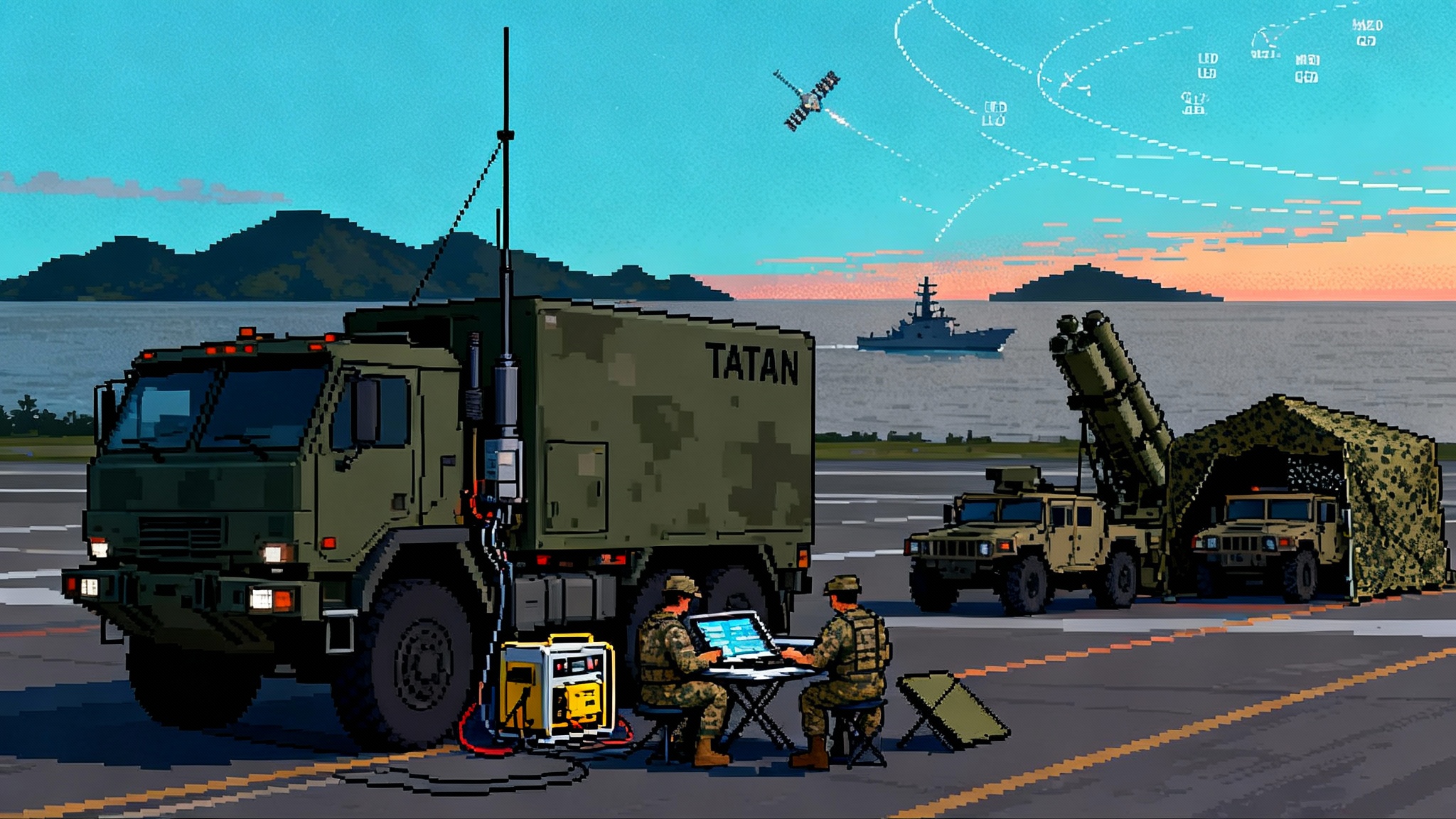

From fixed pads to moving trucks

The U.S. Army’s first Dark Eagle battery rides on heavy trailers, each with two sealed launch canisters. That gives the unit eight ready rounds before reloads, plus the ability to arrive discreetly by road, set up in minutes, fire, and then move. It is not subtle in a parking lot, but in the real world a battery can disperse across farm roads, tree lines, and depots in the same way that modern surface-to-air missile units do. The logistics package is familiar: tractors, ammo resupply vehicles, a battery operations center, and communications nodes that plug into the joint kill chain.

Now layer in lighter mobile launchers. A hypersonic round that fits in a HIMARS-style pod changes basing math in three ways:

- Transport. A C-130 can move a HIMARS truck with podded munitions, which means weeks shorten to days for forward positioning. Pallets and ramps beat heavy-equipment shipping timelines.

- Dispersion. Instead of one large signature that must be protected, commanders can distribute a dozen small signatures that each carry credible reach. That creates many more aim points for an adversary’s targeting cycle and complicates their salvo calculations.

- Host-nation politics. Temporary deployments and exercises with truck-mobile launchers are easier to agree to than permanent new fixed sites. In practice that means more countries can say yes more often, even if the answer is yes for 90 days at a time. For a related Pacific basing arc, see Typhon land-based sea strike.

The Indo-Pacific is already sketching this playbook. The Army’s hypersonic unit deployed its system to Australia during Talisman Sabre in July, a forward employment that stress-tested mobility, sustainment, joint targeting, and host-nation coordination in a realistic setting. The takeaway is simple. If you can drive there, you can base there, and if you can base there, you can deter there. Europe offers a different landscape but similar incentives: road networks, allied training areas, and a growing appetite for distributed long-range fires that can move after every shot.

What this means for deterrence

Deterrence is not a mystical force. It is a math problem that adversaries must solve before they act. Hypersonics complicate that math in three ways that matter to planners in Tokyo, Manila, Warsaw, and Berlin:

- Time. A glide vehicle covering two thousand kilometers in minutes compresses the target’s decision window. That makes command nodes, air defense radars, and launch complexes harder to surge or reposition once a crisis starts.

- Geography. Mobile launchers can appear across a broad arc of roads and ports. This erodes the value of pre-planned strike packages that aimed at fixed sites and expected predictable responses.

- Integration. Hypersonics do not replace other fires. They clear the way. The realistic role is to open gaps by hitting hard problems first. Then longer-range rockets and aircraft exploit those gaps. That sequence is what gives coalitions a credible, conventional way to degrade anti-access systems without climbing the ladder to nuclear thresholds.

The counter-hypersonic job for the next 12 to 24 months

Fielding is not the finish line. It is the starting gun for defenders. Over the next two years, the priority is to turn promising sensors and interceptors into a working kill chain that can handle a maneuvering, dim target in clutter.

-

Space sensing in layers. The new generation of low-Earth orbit infrared satellites can spot and track faint, maneuvering threats where legacy ballistic sensors fall short. The near-term task is not launching more birds. It is making sure their track files flow quickly into fire control for naval and ground shooters. That means operationalizing the handoff from wide-field warning satellites to middle-field sensors that can maintain custody through turns and dips. The Space Force’s use of commercial capacity, including CASR wartime lever for space, is a key enabler.

-

Custody from space to sea to shore. A hypersonic takes odd paths. Data has to stick with it. Ships with new radars, land-based over-the-horizon radars, and airborne infrared sensors need a common track truth. The work is less about one magic radar and more about latencies, formats, and confidence scores that let commanders commit shots without waiting for a perfect picture.

-

Interceptors that buy time now and deeper shots later. Today, the only operational tools with any chance to touch a hypersonic threat are multi-mission missiles like Standard Missile 6 in certain terminal windows, cued by good data. The next rung is a dedicated glide-phase interceptor that can reach out earlier in the threat’s path. Budget choices in 2024 and 2025 slowed that program, so the practical plan for the next two years is better cueing, more shots on hand, and doctrine that treats hypersonic defense as a team sport: jam, decoy, and then intercept.

-

Command and control discipline. If every service writes its own playbook for hypersonic tracks, the result will be missed handoffs. The job this year and next is ruthless standardization. A hypersonic defense rehearsal should look like an airline turnaround: the same checklists, the same timing marks, the same hand signals.

What to watch between now and the end of 2026

- Battery reload cadence. The first Dark Eagle battery is a start, not scale. The number to watch is how many reloads arrive per quarter and how quickly the second battery is equipped. A steady drumbeat signals a maturing industrial base.

- Podded hypersonic demonstrations on mobile launchers. Live fire from a HIMARS-class truck with a smaller hypersonic round would validate much of the promise described in 2025. The specific dates matter less than seeing Army test units run end-to-end: load pod, drive, receive target data, shoot, scoot, and rearm.

- Reusable flight tempo. A sustained pulse of hypersonic test flights at intervals measured in weeks, not quarters, will confirm that reusability is doing its job. Expect incremental objectives: new sensors, guidance tweaks, material coupons. The key is repetition.

- Space sensor integration drills. Watch for exercises where space tracking feeds into Navy and Army shooters in near real time. Success will not always be public, but when commands talk about shared custody of fast, low targets, that is the tell.

Practical actions for policymakers and programs

-

Lock in the supply chain wins. Fund second-source capacity for carbon-carbon, thermal protection resins, and solid rocket motor ingredients. Make those awards multi-year so suppliers invest in furnaces, autoclaves, and people. Specify inspection standards early so new lines do not sit idle waiting for qualification paperwork.

-

Treat mobile basing as a doctrine, not a demo. Codify movement plans, camouflage and deception packages, reload drills, and host-nation logistics for hypersonic units. Write them into theater campaign orders. Practice the boring parts until they are boring.

-

Buy test time like it is fuel. Put reusable flight hours on contract. Tell teams to fly a set number of hypersonic hours per quarter with defined learning objectives. Measure programs by the questions they answer each quarter, not the speeches they give.

-

Close the defense latency gap. Fund the unglamorous middleware that moves space sensor data into fire control systems without human babysitting. Incentivize vendors to deliver tested adapters, not slideware interfaces. Reward units that shave seconds from track handoffs in live exercises.

-

Keep cost as a requirement. For smaller hypersonic rounds, write unit cost targets into the requirement and structure development to protect that number. A hypersonic you can buy by the dozen beats a hypersonic you can brief about.

The bottom line

Milestones matter. In October, the Army could point to an actual heavy hypersonic battery on the path to full armament. In the same season, a young company won work to put a cheaper, smaller hypersonic onto the Army’s favorite truck launcher. Reusable testbeds are turning flight test from a special occasion into a routine. Composites and solid motor lines are adding heat and throughput. Space sensors are finally watching the parts of the sky that matter for maneuvering threats. None of this is hypothetical.

The real test is what happens next. If reloads arrive on schedule, if a podded hypersonic fires from a mobile truck, if space custody feeds a ship or an Army battery with low latency, then 2025 will look like the year hypersonics became normal. Not simple. Not cheap. Just normal. That is the kind of progress that changes planning, alters deterrence, and gives decision makers options they did not have yesterday. Which is the point of the whole enterprise.