The 2025 Transformer Crunch Is Now the Grid Gatekeeper

In 2025, the grid bottleneck is not turbines or panels but transformers. With multi-year lead times, copper and tariff shocks, and a thin workforce, these boxes now set the pace for U.S. power additions. See who benefits, what to fix first, and how to unlock gigawatts faster.

Breaking point in plain sight

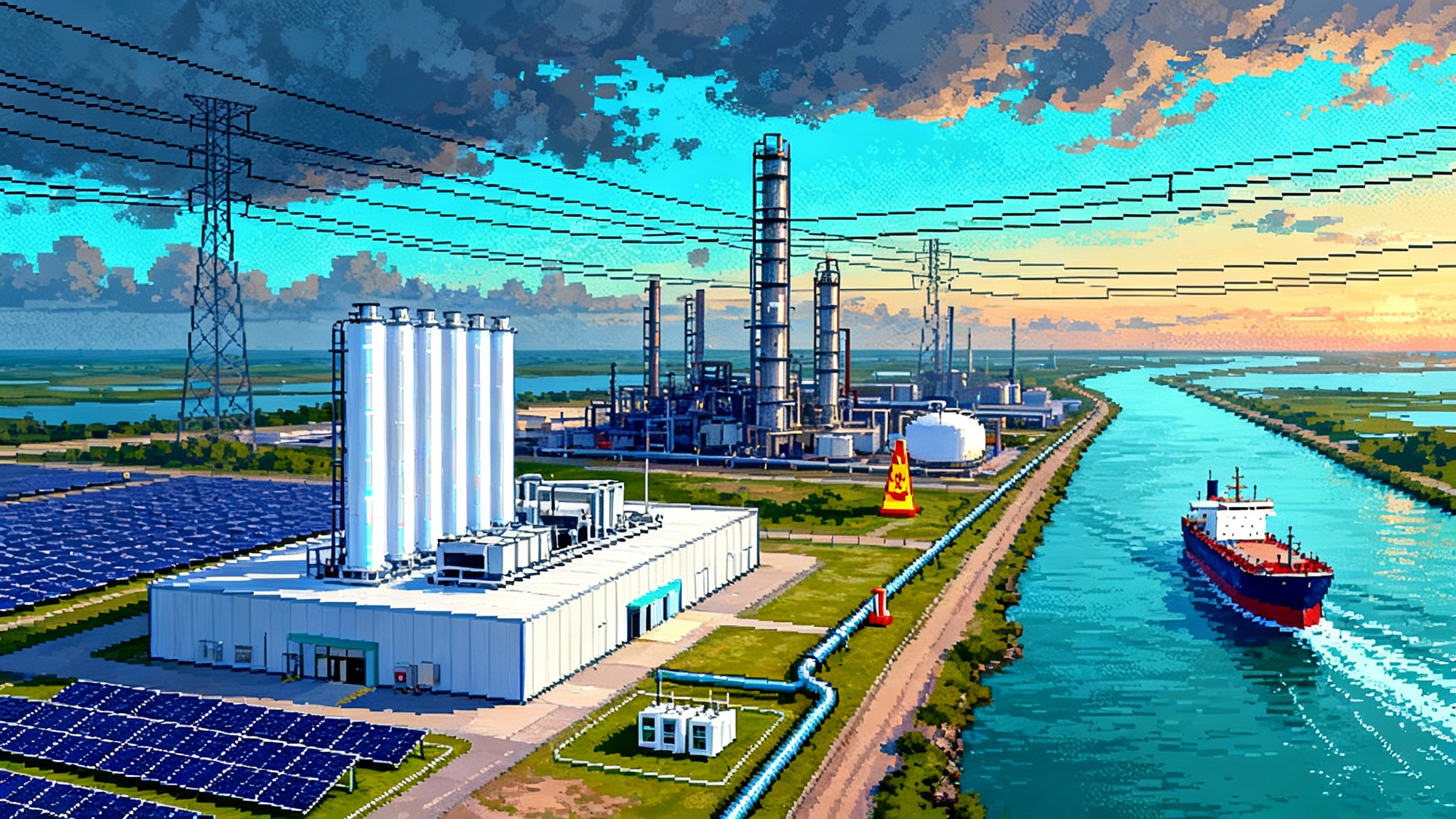

If you want to understand how fast U.S. power can grow in the next three years, stop looking at power plants and start looking at transformers. In 2025, the most telling signals are not about turbines or panels. They are about the boxes of steel, copper, insulation, and precision windings that step voltage up and down and quietly decide when new load or new generation can actually connect.

This year's picture is stark. Industry trackers estimate U.S. power transformers face a double-digit supply shortfall and multi-year queues, with generator step-up units for plants and high-voltage grid transformers repeatedly quoted at more than two years from order to delivery. Distribution transformers have eased from their 2023 peak but remain elevated. Wood Mackenzie puts 2025 deficits at roughly 30 percent for power transformers and 10 percent for distribution units, with lead times that can strand completed projects and delay interconnections. Wood Mackenzie's 2025 deficit forecast is one of several red flags utilities and developers have been acting on.

At the same time, reliability watchdogs have warned that rising load, extreme weather, and the pace of retirements leave several regions vulnerable during stressed conditions. Many of those warnings now carry a supply-chain footnote: even when a region wants to add capacity or reinforce a corridor, transformers can be the gating item.

Think of transformers as oxygen canisters in a hospital. You can build operating rooms and recruit surgeons, but without canisters you can only run so many procedures. America's grid spent decades drawing from a global pool of transformer canisters that seemed inexhaustible. In 2025, that assumption broke.

The 2025 signals that changed the conversation

- Fresh deficit math. Sector analysts and trade groups now converge on the same picture: structural shortages for the largest units, with distribution gear improving but not back to pre-pandemic norms. The details vary by utility spec and voltage class, but the direction is unmistakable.

- Reliability reminders. NERC's seasonal outlooks and regional operator briefings in 2025 increased focus on non-energy risks, including equipment supply and interconnection timing. Interconnection queues and planning models cannot clear if critical gear arrives late. See how inverter rules intersect with protection requirements in FERC's 2025 IBR rule.

- OEM buildouts with long maturation. Leading manufacturers have announced large U.S. investments, but many of those plants or lines will not ship their first large units until 2027 or later. Siemens Energy, for example, targeted initial U.S. production of large transformers in early 2027 at its Charlotte site, underscoring how slow this category is to scale compared with inverter or battery assembly. Siemens 2027 U.S. transformer plan shows the calendar utilities must plan against.

Where the constraints bite

1) Lead times and customization physics

Large power transformers and generator step-up units are engineered products, not catalog items. Each one must meet utility protection philosophies, site clearances, tap ranges, seismic requirements, cooling packages, sound limits, bushings, and accessory preferences. In practice, that means every drawing package can become a bespoke project. A few months of redesign or component re-sourcing on paper often translates to quarters of delay on the factory floor.

Over the past two years, average quoted lead times for big iron repeatedly crossed 24 months, with the high end pressing 36 months. Even a small shift in order mix toward tank sizes beyond a factory's lifting capacity can cascade into scheduling conflicts, because those bays and cranes are the real bottlenecks.

For distribution transformers, backlogs have come off their peak but have not returned to historical norms. Utilities that standardized around common kVA ratings, voltage combinations, and accessory sets have seen materially better delivery performance. Utilities that kept dozens of legacy variants often still queue longer.

2) Copper, electrical steel, and tariff friction

Copper is the blood of a transformer. Price spikes through 2025 raised working capital needs and tightened bid validity windows. Grain-oriented electrical steel is the skeleton. The U.S. currently relies on a thin domestic base for GOES and volatile import channels. Policy has added new variables. Steel and aluminum tariffs were increased in mid-2025 and exclusion processes tightened, affecting both raw coil and fabricated components. Talk of copper trade actions and widening spreads between U.S. and global prices amplified the uncertainty. The net effect is straightforward: more bid escalators, more provisional timelines, and greater price dispersion across similar units.

3) Workforce and factory learning curves

Transformer manufacturing is heavy craft. Coil winding, core stacking, vacuum drying, and oil processing are skills developed over years. Plants can add buildings faster than they can add master winders or test engineers. That reality shows up in yield and rework rates when production ramps. Many U.S. plants also rely on a subcontractor ecosystem for radiators, bushings, tap changers, and control cabinets. If one of those suppliers stumbles, the final assembly line waits.

4) Interconnection and protection dependencies

Even when a region has enough generation, energizing it often requires transformer-intensive substation work. Generator step-up transformers, station service transformers, shunt reactors with tap changers, and autotransformers for network upgrades are all part of the same constrained family. Grid planners can approve a project, but if a 400 megavolt-amps autotransformer is three years out, the in-service date moves.

Who benefits from the retooling wave

- Global OEMs with U.S. footprints. Hitachi Energy, Siemens Energy, GE Vernova and Prolec GE, SPX Transformer Solutions, and Howard Industries gain pricing power and backlog visibility. As new lines open, they can prioritize long-horizon, standardized blocks that improve factory utilization.

- Component specialists. Makers of high-voltage bushings, tap changers, radiators, and instrument transformers can ride a multi-year upcycle, especially if they qualify as domestic content. Their delivery performance can determine whether a finished transformer ships on time.

- Upstream metals producers. Domestic GOES providers and copper fabricators benefit from tariff cushions and long-dated offtake agreements, though volatile policy and price cycles require careful hedging.

- Service and refurbishment firms. Mid-life rebuilds, mobile transformer fleets, and emergency spares programs are seeing renewed interest as developers and utilities seek capacity insurance while they wait for new units.

The fastest fixes utilities and developers can execute for 2026-2028

Below is a focused playbook that trades wish lists for actions a typical utility or developer can commit to in the next two quarters, with an eye on placing steel and copper where it matters.

1) Design standardization that OEMs can actually build

- Collapse variants. Cut the number of accepted kVA ratings, primary and secondary voltage combinations, and accessory configs. Use a walled garden approach: a small set of standard drawings with narrowly defined options and a separate, slower lane for true one-offs.

- Align on accessories. Pre-approve a short list of bushings, tap changers, and relay packages with alternatives, so factories can swap in second-source parts without rework. That single choice can erase weeks when a supplier has a hiccup.

- Adopt utility consortium standards. Where possible, join or form regional buying clubs that publish common specs. DOE's outreach has highlighted how tens of thousands of distribution transformer variants slow production. The fewer prints, the faster the bays turn.

How it unlocks gigawatts: Factories slot standardized designs into repeatable workflows. More of the schedule becomes drumbeat work rather than engineering change orders, so delivery risk shrinks and throughput rises.

2) Long-horizon procurement with real commitments

- Place multiyear, multi-unit blocks tied to realistic in-service dates. Include price escalators pegged to copper and GOES indices and a clear schedule of firm need dates. OEMs will allocate limited slots to buyers who give planning certainty.

- Pre-buy long-lead components. For major projects, purchase bushings, tap changers, and control cabinets early and assign them to future units. Some utilities now keep a small inventory of universal components to de-risk builds.

- Add cancellation backstops. Offer limited buy-back or redeployment rights that allow OEMs to reassign a unit if a project slips. That helps factories avoid stranded work-in-process and keeps your place in line.

How it unlocks gigawatts: Firm, forward orders justify staffing and component orders today. That accelerates substation and plant energization windows in 2027-2028.

3) Domestic manufacturing scale-ups with shared risk

- Co-invest in capacity. For mission-critical corridors or plant fleets, consider structured offtake agreements that support a new production line or test bay. Tie incentives to proven throughput milestones, not ribbon cuttings.

- Support workforce pipelines. Fund scholarships and apprenticeships for coil winding, welding, and test engineering at nearby technical colleges. Reserve factory rotations for your staff to build operator-to-owner trust and speed site acceptance.

- Reward on-time, not just on-spec. Include delivery performance incentives in contracts. Paying a small premium for on-time energization often beats a lower bid that arrives six months late.

How it unlocks gigawatts: Shared-risk models bring new bays online earlier and stabilize yields. That pulls forward energization dates for whole clusters of projects.

4) Component modularization and interchangeability

- Standardize bushing patterns and turret designs so a small set of spare bushings fits most of your fleet. Do the same for tap changer models and control cabinets.

- Specify modular radiators and quick-connect oil processing interfaces to speed field swaps and repairs.

- Use common accessory voltages, wiring conventions, and cabinet layouts so technicians can move between sites without retraining.

How it unlocks gigawatts: Modular spares turn multi-week factory fixes into field repairs measured in days and keep existing capacity online while new gear is scarce.

5) Spares, refurbishment, and mobile fleets

- Build a shared regional spare pool for critical autotransformer sizes and generator step-ups with neighboring utilities or developers. Establish custody rules, transportation plans, and test protocols now.

- Contract for mid-life refurbishments to extend units that are approaching thermal or moisture limits. A two-year life extension can bridge to an on-order replacement.

- Expand mobile transformer fleets sized for your typical substation capacities. A handful of mobile units can cover dozens of contingency scenarios and reduce outage risk.

How it unlocks gigawatts: Every avoided forced outage or accelerated restoration is capacity you do not need to replace with new gear during the crunch years.

6) Interconnection and protection design for speed

- Design substation packages around available transformer sizes rather than idealized specs. Accept slightly higher losses or different impedance windows if it means shipping in 2027 instead of 2029.

- Pre-permit sites and standard foundations for multiple transformer footprints so you can accept alternate tank geometries without restarting civil work.

- Coordinate protection settings with equipment availability to avoid re-studies when a substitute transformer model is used.

How it unlocks gigawatts: Flexible engineering reduces change orders, keeps permits valid, and lets you take the first buildable option.

7) Contracts that reflect tariff and commodity reality

- Add transparent price adjustment formulas tied to copper and GOES benchmarks. This reduces the need for short bid validity windows and lets procurement proceed without gambling on month-to-month price swings.

- Include contingency plans for tariff changes. Spell out how duties will be handled and what substitutions are acceptable if a specific import channel becomes uneconomic.

How it unlocks gigawatts: Deals close faster and stay closed when markets move, avoiding rebids that reset the clock.

A quick playbook by segment

For electric utilities

- Cut your distribution transformer variants by half within 12 months and align with at least one regional consortium spec.

- Place two-year rolling orders for your top five kVA ratings and for any autotransformer sizes that control key transfer paths.

- Build a joint spare pool and a mobile fleet plan with your neighbors. Run an annual logistics drill so everyone knows who moves what, and when.

For data center developers

- Procure generator step-up transformers and main substation transformers as soon as land control is secured. Many successful programs now place transformer orders before building permits. For demand context, see our AI's gigawatt appetite analysis.

- Design around the most buildable transformer specs, not the perfect ones. A 1 percent loss penalty is often worth an 18-month schedule gain.

- Pair long-lead transformer orders with backup grid connection options. Where possible, phase projects so early halls can energize from existing substations while the dedicated primary station is built.

For renewable and storage developers

- Order generator step-up transformers with flexible impedance and winding options that your interconnection study will accept. Ask the utility to pre-approve alternates.

- Co-locate projects near substations with existing spare capacity or shared spare coverage. Avoid bespoke sizes that have thin global supply.

- Consider at-risk procurement for step-up units when offtake is strong. The carrying cost is frequently lower than the value lost to delayed commercial operation.

For OEMs and component suppliers

- Publish a standard menu of designs and lead times and reward buyers who stay within that menu.

- Offer a component substitution matrix that shows acceptable alternates without a full re-approval cycle.

- Expand field refurbishment and mobile capabilities as a service line. It smooths revenue while new lines scale and deepens customer relationships.

What to watch through 2026

- Delivery curves at new U.S. transformer lines. Announcements are not shipments. The first 12 months of a new bay often determine whether a plant hits its quoted cadence in year two.

- Tariff policy and copper. Steel and aluminum duties increased in 2025 and copper markets were volatile. Watch for policy stability and domestic investment signals that could take pressure off bid escalators.

- NERC seasonal assessments and interconnection reforms. Reliability outlooks will show whether equipment bottlenecks continue to hold back capacity additions, especially in regions with rapidly growing load from data centers and industrial investments. For the transmission angle, read our 2026 transmission pivot outlook.

The takeaway for 2025's crunch years

Transformers are no longer background equipment. They are the pacing item for data centers coming online, for renewables reaching commercial operation, and for grid upgrades that keep the lights on during heat waves and cold snaps. The good news is that many of the fastest fixes do not require an act of Congress. They require disciplined standardization, credible multi-year orders, and modular thinking about components and spares. The harder work is cultural: letting go of thousands of legacy specs, accepting good-enough losses in exchange for sooner energization, and signing contracts that share risk rather than shuffle it.

Utilities and developers that act on those specifics will unlock gigawatts sooner between 2026 and 2028. Those who wait for the perfect factory to arrive will compete for the same scarce slots, at higher prices, for longer. The grid is telling us exactly how fast it can grow. Listen to the transformer bays.